Catalog excerpts

What you should know about Ipsen’s plant technology. Hard work wins

Open the catalog to page 1

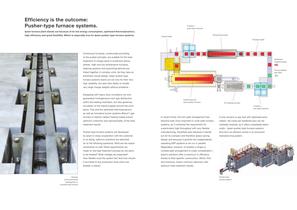

In recent times, the twin-path arrangement has become even more important in multi-path furnace systems, as it combines the requirement for a particularly high throughput with very flexible manufacturing. Doubtless also because it stands out for its compact and therefore space-saving design and because it permits two independently operating ERP systems to be run in parallel. Regardless, however, of whether a single or multiple path arrangement is under consideration – Ipsen’s solutions offer a maximum in efficiency thanks to their specific construction. Which, first and foremost, means...

Open the catalog to page 2

Thanks to their high throughput, rotary hearth furnace systems, are preferred, just like pushertype furnace systems, for processing large production-run, identical parts. Two different versions are available: Single furnaces, which can be charged and discharged either automatically or manually – and multiple chamber furnaces, so-called ring furnaces, which can be linked with other plant components. The two furnace types are ideally suited to single charging and discharging, but can also be used, without any adaptation for re-heating prior to press hardening. When equipped with additional...

Open the catalog to page 3

Continuous and semi-continuous Ipsen systems offer clear advantages: they help in handling large throughputs, save energy and ensure constant, highest possible levels of quality consistency. The Ipsen AutoMag® software solution was designed so that its benefits could be optimally used with all different system versions. In addition it offers highly flexible process and procedure control, optimisation of batch sizes and chargespecific logging. This permits precise control and monitoring of all the heating and cooling zones of a system in a charge-specific manner – the charge tracking...

Open the catalog to page 4

If you require further information or would like to know more about our company and the products we make, please contact us. We look forward to hearing from you! Ipsen International GmbH Flutstraße 78 47533 Kleve Germany Telephone +49 2821 8 04-0 info@ipsen.de · www.ipsen.de Hard work wins © Ipsen 10 2007 For over 60 years Ipsen has been finding new ways of producing steel of ever improving quality using the company’s innovative, proprietary technologies, such as the AvaC® process (low-pressure carburising), the SolNit® process (solution nitriding) and the recently developed HybridCarb...

Open the catalog to page 5All Ipsen International GmbH catalogs and technical brochures

-

IP-704 Fluid

2 Pages

-

Ipsen HydroNit Sensor

2 Pages

-

Ipsen Brazing

2 Pages

-

Ipsen Titan

9 Pages

-

Ipsen HybridCarb

3 Pages

-

Ipsen AutoMag® 4.0

3 Pages

Archived catalogs

-

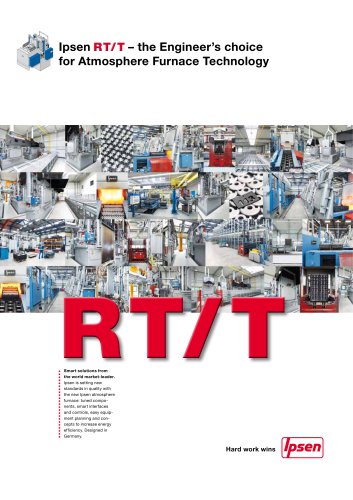

Atmosphere Technology

5 Pages

-

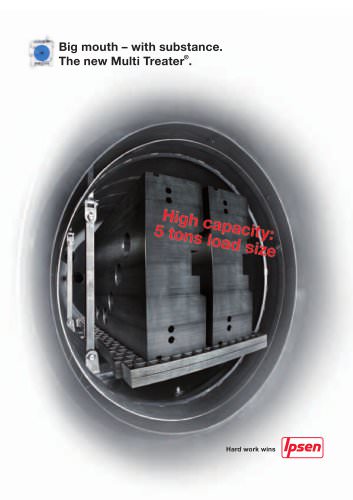

Ipsen Multi Treater

5 Pages

-

Carb-o-Prof® 4.0

3 Pages

-

Ipsen SolNit

3 Pages

-

Ipsen Turbo²Treater

6 Pages

-

Wind Energy

5 Pages

-

Ipsen Vacuum Technology

6 Pages

-

Ipsen SuperQuench

3 Pages