Catalog excerpts

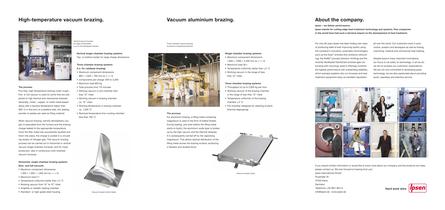

Vacuum brazing is better … Brazing made easy – with vacuum furnaces by Ipsen. This is what vacuum brazing is for. Many high-grade stainless steel, ceramic and aluminium products can only be manufactured in an economically- and environmentally sound manner using vacuum brazing. To meet these needs, Medical technology – brazed component for directing beam concentration in radiation therapy Ipsen offers manual, semi- and fully-automatic single- and multi-chamber vacuum furnaces The brazed joints produced by this method are also superior. They are significantly more reli- able and stronger because there is no chance of They are increasingly manufactured using vacuum flux material entering the joints and reducing their mechanical strength or the corrosion resistance of Heat exchangers and heating tubes The process of choice for the durable connection Image: H & ST High temperature brazing in rough-, fine- or full- of heat exchanger components and heating tubes is high-temperature brazing, for example using vacuum is especially well-suited to thermally and mechanically highly-stressable joints. It’s no won- Turbine blades der that vacuum brazing has become the standard Turbine blades are subjected to huge stresses for component manufacturing in safety-critical in practice. By brazing them in vacuum, especially Plate heat exchanger components can be joined applications such as aerospace technology. with the perfect uniform heating, their joints are quickly, simply and reliably using vacuum brazing. stainless steel or copper filler material. made highly reliable. The advantages of Ipsen vacuum brazing equipment are plain to see: fully definable furnace Vacuum brazing is more an more becoming Flux-free brazing is especially environmentally atmosphere, fast temperature regulation, and the choice in manufacturing of stainless steel friendly because no aggressive fluxing agents guaranteed almost ideal temperature uniformity. are applied to the components. This renders the Furthermore, Ipsen’s vacuum brazing technology removal of flux residues and finishing treatments The new Ipsen all-metal chamber for hard- and hightemperature brazing offers exemplary energy efficiency. Titan 6 – the new, economical vacuum-furnace for all brazing applications Brazing component assembly Image: H & ST Honeycombs and mounting components The highly mechanically stressed joints of connectors, including honeycomb structures, nuts, screws and rivets, are brazed in vacuum furnaces. Hard work wins Drill bit with hard metal cutting pate, hardened and attached in a single process

Open the catalog to page 1

High-temperature vacuum brazing. Vacuum aluminium brazing. About the company. Ipsen – we deliver performance. Ipsen stands for cutting edge heat treatment technology and systems. Few companies in the world have had such a decisive impact on the development of heat treatment. Vertical vacuum furnace for large components, e. g. for the aerospace industry For over 60 years Ipsen has been finding new ways Vertical single-chamber brazing systems Single chamber brazing systems Top- or bottom-loader for large charge dimensions • Maximum component dimensions 1,600 × 7,800 × 2,400 mm (w × l × h)...

Open the catalog to page 2All Ipsen International GmbH catalogs and technical brochures

-

IP-704 Fluid

2 Pages

-

Ipsen Plant Technology

7 Pages

-

Ipsen HydroNit Sensor

2 Pages

-

Ipsen Titan

9 Pages

-

Ipsen HybridCarb

3 Pages

-

Ipsen AutoMag® 4.0

3 Pages

Archived catalogs

-

Atmosphere Technology

5 Pages

-

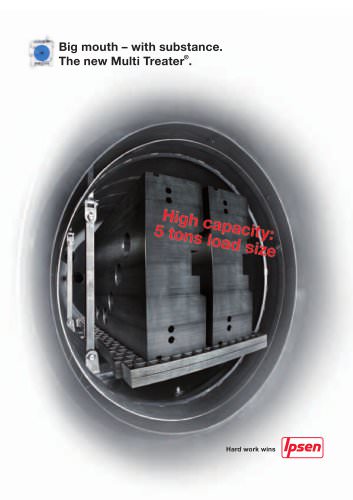

Ipsen Multi Treater

5 Pages

-

Carb-o-Prof® 4.0

3 Pages

-

Ipsen SolNit

3 Pages

-

Ipsen Turbo²Treater

6 Pages

-

Wind Energy

5 Pages

-

Ipsen Vacuum Technology

6 Pages

-

Ipsen SuperQuench

3 Pages