Catalog excerpts

Product overview Interroll Drum Motors unit load handling

Open the catalog to page 1

S Series Asynchronous i Series Drum Motors Frequency inverters, Options, Accessories Synchronous D Series Interroll Drum Motors are extremely efficient with efficiencies up to 83% Interroll Drum Motors: Efficient, space-saving, hygienic Different material handling tasks require different solutions. However, the requirements are always the same: high efficiency, simple assembly, broad performance spectrum and maintenance-free. Design that meets space-saving and hygiene requirements Interroll Drum Motors are the perfect drive solution for material handling equipment in numerous industrial...

Open the catalog to page 2

There are many reasons… … for using space-saving Interroll Drum Motors instead of conventional motors. Because the motor, gearbox and bearings are mounted within the drum shell, a drum motor takes up much less space than other motors. As a result, the belt conveyors have a more compact design and a more space-saving installation. The installation of Interroll Drum Motors is significantly faster and easier – less than a quarter of the installation time for a drive with many individual components. Fewer components mean reduced costs for conveyor design and purchasing of parts. Wear-resistant...

Open the catalog to page 3

Interroll Drum Motor overview Gear material Rated Power Friction drive belt Positive drive belt Without belt Rated torque Belt pull* Velocity of the shell* Shell length SL Note: * Values of belt pull and velocity are given for the shown diameter For detailed technical data and further in

Open the catalog to page 4

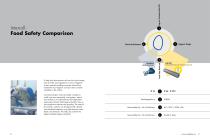

Ingress Protection Rate (IP) Interroll: Food Safety Comparison Chemical Resistance Hygienic Design Standard GEAR MOTOR To help food manufacturers all over the world comply with all of the strict regulations in terms of hygiene in their material handling processes, Interroll has created the most hygienic conveyor drive currently available on the market. Conventional gear motors are bulky, complex to install, and most importantly, non-hygienic: tested and verified as non-cleanable by the independent organization Danish Technological Institute, they require expensive cabinets and guarding. The...

Open the catalog to page 5

Hexagon shell with stainless steel sprockets Cylindrical shell with key and sprockets Torque transmission: a perfect solution for every conveyor belt The torque of the drum motor can be transmitted in different ways. Depending on the conveyor belt – plastic modular belts, positive drive solid homogeneous belts, belts made of steel braid or wire or the classic friction-driven belts made of rubber, PVC and PU – Interroll offers the perfect torque transmission method for every application. Profiled lagging for plastic modular belts Frictional lagging with groove Interroll Centre of Excellence...

Open the catalog to page 6

About Interroll Established in 1959 Interroll has grown to become the world’s leading supplier of key products for intralogistics. Whether boxes, pallets or soft goods are to be handled, no other supplier has such a comprehensive range of products on offer. That is why system integrators, OEMs and operators select Interroll as their partner for their internal logistics business. Worldwide. The Interroll global network ensures quick delivery and superior service for every local customer. We inspire our customers and provide opportunities for them to increase efficiency. interroll.com...

Open the catalog to page 7All Interroll catalogs and technical brochures

-

CONTROLS ZONECONTROL

3 Pages

-

CONVEYOR MODULES

131 Pages

-

DRUM MOTORS

198 Pages

-

CONVEYOR ROLLERS

218 Pages

-

RM6008

2 Pages

-

ROLLERS SERIES 1200

3 Pages

-

ROLLERS SERIES 1100

3 Pages

-

Interroll Drum Motor 113C

2 Pages

-

SERIES EC5000

7 Pages

-

HP5424

3 Pages

-

Interroll Spiral Lift

1 Pages

-

RollerDrive EC310

8 Pages

-

CART PUSHBACK

8 Pages

-

CARTON FLOW

28 Pages

-

PALLET FLOW

10 Pages

-

NEW CONVEYOR ROLLERS CATALOG

142 Pages

-

BM 8350

1 Pages

-

CONTROLS POWERCONTROL

2 Pages

-

efficient conveyor systems

8 Pages

-

Industry Fact Sheet

8 Pages

-

Intelligent Solutions

20 Pages

-

Drum Motors in Food Processing

20 Pages

-

rollers & rollerdrive

17 Pages

-

RollerDrive & Controls

20 Pages

-

D R U M M O T O R S

138 Pages

-

Conveyor Rollers

117 Pages

-

Interroll Drum Motors

164 Pages

-

Supermarket Solutions

50 Pages

-

Idlers and Pulleys

26 Pages

-

4/08 Poly-Vee

2 Pages

Archived catalogs

-

Conveyor Lines Catalogue

81 Pages

-

Synchronous Drum Motor

28 Pages