Catalog excerpts

Inspired by efficiency Established in 1959 Interroll has grown to become the world‘s leading supplier of key products for internal logistics. Whether boxes, pallets or soft goods are to be handled, no other supplier has such a complete product range on offer. That is why system integrators, OEMs and operators select Interroll as their partner for their internal logistics business. Worldwide. The Interroll global network ensures quick delivery and superior service for every local customer. We inspire our customers and provide opportunities for them to increase efficiency. Interroll reserves the right to modify the technical characteristics of all its products at any time.Technical information, dimensions, data and characteristics are indicative only. © Interroll 2014 Drum mOtors

Open the catalog to page 1

Which drum motor is suitable for your application? AC Asynchronous Motors AC" Permanent Magnet Synchronous Motors Friction Drive Belt Positive Drive Belt or All Belt Types or Application Non-Belt Application no belt Drum Motor Drum Motor Choose Drum Drum Motor Interroll Woldwide Group 2 Interroll Product Overview 6 Introduction to Interroll Drum Motors 8 Applications for Interroll Drum Motors 10 Standard Asynchronous Drum Motors for All Applications 12 Standard Synchronous Drum Motors for All Applications 92 IFI - IP55 Interroll Frequency Inverter 120 Lagging for Friction Drive Belts 128...

Open the catalog to page 2

The Worldwide Interroll G roup The Interroll Group is one of the world‘s leading specialists for in-house logistics. The company, which is listed on the stock exchange and has its headquarters in Switzerland, employs some 1,600 people in 31 companies around the globe. Holding Global Centers of Excellence Sales/Production Agents/Distributors Our products can be found primarily in the food industry, in airport logistics, in the parcel, postal and courier sector, in distribution, and in various branches of the industry. This includes: Easy-to-integrate drive solutions such as drum motors for...

Open the catalog to page 3

The Hear t of In -House Logistic s With an experienced eye for the big picture, we offer you the kind of products that are versatile and essential building blocks in the portfolio of any successful planner or developer. Versatile and reliable core products ensure a dynamic, efficient Millions of different individual items travel through the world’s Economical and user-friendly: the dynamic storage solution material flow across all continents and in all sectors: flow of goods every day and must be delivered on time that operates without energy. It is designed for fast-moving Conveyor rollers...

Open the catalog to page 4

Product Overview Order picking racking with Carton Flow (Roller Track) Order picking racking with Flex Flow Conveyor Rollers and Accessories Idler Pulleys Crossbelt Sorters Belt Curves Belt Conveyor Modules Conveyor Modules for zero pressure accumulation (ZPA) Conveyors Standard Asynchronous Drum Motors Standard Synchronous Drum Motors Interroll IFI–IP55 Frequency Inverter Options Accessories Drum Motors, Idler Pulleys, brackets LIFO - Pallet flow storage modules (Cart Pushback) LIFO - Pallet flow storage modules (Conveyor Rollers) FIFO - Pallet flow storage modules (Conveyor Rollers)...

Open the catalog to page 5

99 Hard-wearing 99 Hygienic design 99 Energy efficient Interroll Drum Motors are much quicker and easier to install than conventional drive systems, requiring less than a quarter of the time needed to fit a multicomponent drive. Fewer parts mean reduced costs for conveyor design and purchasing of parts. Interroll Drum Motors will keep operating at 100 % even in harmful environmental conditions, such as water, dust, grit, chemicals, grease, oil and even during high pressure wash-down procedures. Due to the smooth, stainless steel finish and the hermetically sealed and totally enclosed...

Open the catalog to page 6

Friction drive belts Positive drive belts: Plastic modular belts Positive drive belts: Thermoplastic homogeneous belts Non-belt applications Without frequency inverter Standard Drum Motor Motors for applications with positive drive belts or no belts Motors for applications with positive drive belts or no belts Motors for applications with positive drive belts or no belts With frequency inverter Standard Asynchronous Drum Motor Standard Asynchronous Drum Motor Standard Asynchronous Drum Motor Standard Asynchronous Drum Motor Sensor-less or Servo Driver Standard Synchronous Drum Motor...

Open the catalog to page 7

Standard Asynchronous Drum Motors Overview Gear material Rated power Rated torque Belt pull* Velocity of the shell* Shell length SL Friction drive belt ü Positive drive belt û Without belt Note: *Values of Belt pull and velocity are given for the shown diameter. Standard Synchronous Drum Motors p 92 Options p 126 Refer to the Planning Section from p 194 for help with planning and design

Open the catalog to page 8

Standard Asynchronous Compact drive for small light-duty conveyors Product Description Because of its strength, reliability and zero maintenance, this drum motor is perfect for small infeed conveyors, You can choose the following versions of drum body components and electrical connection. The versions depend on the material of the components. 99 Small light-duty conveyors 99 Light-duty packaging equipment 99 Cross belt feed conveyors 99 3-phase or 1-phase AC induction motor 99 Lightweight 99 Maintenance-free (with aluminium shaft caps) 99 Integral thermal motor protection 99 Technopolymer...

Open the catalog to page 9

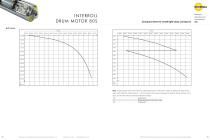

Interroll D r u m M oto r 8 0 S Product Range Standard Asynchronous Compact drive for small light-duty conveyors accordance with the configurator at the end of the catalogue. All data and values in this catalogue refer to 50 Hz operation. Mechanical data for 3-phase motors PN Mechanical data for 1-phase motors The following tables give an overview of the possible motor versions. When ordering, please specify the version in Motor versions Drum Motors Overview of Standard Asynchronous Drum Motors p 12 Rated power Number of poles Gear stages Gear ratio Rated velocity of the shell Rated...

Open the catalog to page 10

Standard Asynchronous Compact drive for small light-duty conveyors Note: To get the right value of the maximum allowed belt tension, first find the maximum allowed TE value for the drum motor RPM. For motors with SL > 402 mm,check if the maximum allowed TE value for the SL is lower. In this case, use the lower value as maximum allowed TE value. TE nA SL Overview of Standard Asynchronous Drum Motors p 12 Belt Tension Rated revolutions of the drum shell Shell length Refer to the Planning Section from p 194 for help with planning and design

Open the catalog to page 11All Interroll catalogs and technical brochures

-

CONTROLS ZONECONTROL

3 Pages

-

CONVEYOR MODULES

131 Pages

-

DRUM MOTORS

198 Pages

-

CONVEYOR ROLLERS

218 Pages

-

RM6008

2 Pages

-

ROLLERS SERIES 1200

3 Pages

-

ROLLERS SERIES 1100

3 Pages

-

Interroll Drum Motor 113C

2 Pages

-

SERIES EC5000

7 Pages

-

HP5424

3 Pages

-

Interroll Spiral Lift

1 Pages

-

RollerDrive EC310

8 Pages

-

CART PUSHBACK

8 Pages

-

CARTON FLOW

28 Pages

-

PALLET FLOW

10 Pages

-

NEW CONVEYOR ROLLERS CATALOG

142 Pages

-

BM 8350

1 Pages

-

CONTROLS POWERCONTROL

2 Pages

-

efficient conveyor systems

8 Pages

-

Industry Fact Sheet

8 Pages

-

Intelligent Solutions

20 Pages

-

Drum Motors in Food Processing

20 Pages

-

rollers & rollerdrive

17 Pages

-

Drum Motors Overview

7 Pages

-

RollerDrive & Controls

20 Pages

-

Conveyor Rollers

117 Pages

-

Interroll Drum Motors

164 Pages

-

Supermarket Solutions

50 Pages

-

Idlers and Pulleys

26 Pages

-

4/08 Poly-Vee

2 Pages

Archived catalogs

-

Conveyor Lines Catalogue

81 Pages

-

Synchronous Drum Motor

28 Pages