Catalog excerpts

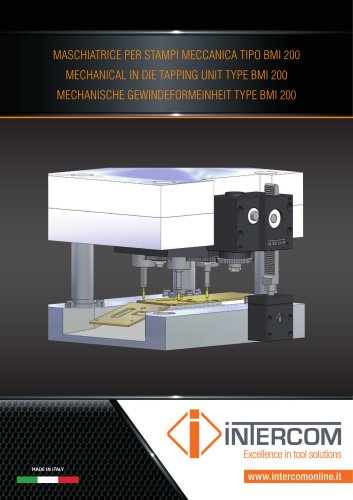

Tapping unit type

Open the catalog to page 2

Tapping unit type

Open the catalog to page 3

Tapping unit type Threading by high velocity; up to 150 strokes/min (according to the diameter, height and material to thread) Easy installation and maintenance The unit is compact and speed, with an electrical-mechanical functioning, without any compressed air The threading operation is independet from any die stroke, in each position: horizontal, vertical or inclined Reduced spaces Automatical approach of the tap to the hole Automatical tap lubrication at each stroke Torque controlled Control that each thread has been properly done Thread on dead holes Left threading (on request) Multiple...

Open the catalog to page 4

How many holes to thread: Time required for threading operation: Threading angle B (see at page 07) Send by fax at the +39 02 95300023 or by e-mail at intercom@intercomonline.it ilMlERCOM

Open the catalog to page 5

INTERCOM Ausrüster was das formen von Gewinden betrifft, öle geeignet für Kunststoff-Formen und Gewindeformer für hohe Leistungen. Minimal lubrication pumps Pumps can work with different kinds of lubricants, high viscosity oils and light oils, wich can be carefully controlled. Suitable for cold steel deformation processes. It gives high performances in the fine blanking, traditional blanking, drawing, bending, minting and by the use of rolling taps, for both steels and stainless steels. Minimal pumps emit a preset quantity of lubricant as an instant spray, just after receiving an electrical...

Open the catalog to page 6

The smaller is the angle of material feed, the greater will be the time for threading, (more strokes / min). Rolling thread example End threading controller To check the production is 100% properly executed

Open the catalog to page 7

The electronic tapping unit is a unit that can make threading operations inside the dies and in special settings, in a very easy and simple way, autonomously, and independently from the stroke of the die. It works with a brushless motor and with a servo driver that control each threading step. Just one start is enough to begin threading process independently and quickly, always with the possibility to regulate the speed and the threading depth. It is also possible to control the threading has been properly executed. @ MOTOR CABLE @ POWER SUPPLY SOCKET @ MASTER ON @ PANEL CONTROL PANEL...

Open the catalog to page 8

NEW CONSOLE ELECTRICAL CHARACTERISTICS OF 2-UNITS CONTROL (TOUCH SCREEN VERSION 7"): CONSOLE ELECTRICAL CHARACTERISTICS FROM 4 TO 6 UNITS CONTROL (TOUCH SCREEN VERSION 10"):* Power supply: single-phase 230 Vac (+ 15%, -15%) 50 Hz (± 3 Hz) Power supply: three-phases 400 Vac (+ 15%, -15%) 50 Hz (± 3 Hz) Maximum absorbed current: 16 A Maximum absorbed current: 32 A Approximate dimensions of the console, inclusive of the overall dimensions of the connectors and the flashing light: height 1300, width 700, depth 500 (dimensions in mm) Approximate dimensions of the console, inclusive of the...

Open the catalog to page 9

Example of application by presses like Bihler or similar Example of application with 6 tapping units by components for automotive industry UP TO 8 THREADINGS flTH ONE CONSOLE

Open the catalog to page 10

PRODUCTS Mechanical in die tapping units SERVICE MORE THAN 30 YEARS EXPERIENCE, IN SPECIFIC SOLUTION FOR EVERY SITUATION AFTER SALES ASSISTANCE ALWAYS THINKING ON NEW SOLUTIONS Please visit our Web Site DOWNLOAD OUR TECHNICAL FILES

Open the catalog to page 11

Excellence in tool solutions Via C. Cattaneo 18/22 - 20064 Gorgonzola (Milano) Tel. +39 02 95300202 Fax +39 02 95300023 www.intercomonline.it - intercom@intercomonline.it

Open the catalog to page 12All Intercom s.r.l. catalogs and technical brochures

-

Springs for wire molds

28 Pages

-

Ground Steels

58 Pages

-

Mechanical tapping Unit

12 Pages

-

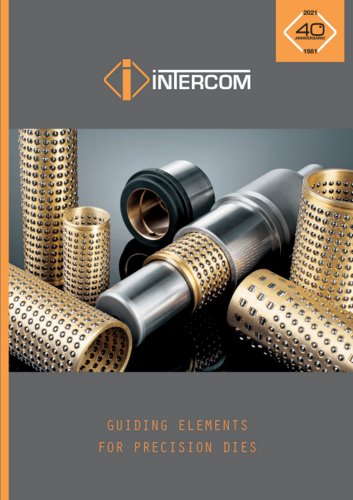

STANDARD GUIDE ELEMENTS

214 Pages