Catalog excerpts

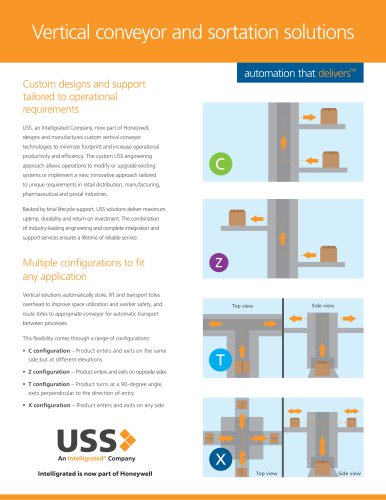

automation that delivers™ Custom designs and support tailored to operational requirements USS, an Intelligrated Company, now part of Honeywell, designs and manufactures custom vertical conveyor technologies to minimize footprint and increase operational productivity and efficiency. The custom USS engineering approach allows operations to modify or upgrade existing systems or implement a new, innovative approach tailored to unique requirements in retail distribution, manufacturing, pharmaceutical and postal industries. Backed by total lifecycle support, USS solutions deliver maximum uptime, durability and return on investment. The combination of industry-leading engineering and complete integration and support services ensures a lifetime of reliable service. Multiple configurations to fit any application Vertical solutions automatically store, lift and transport totes overhead to improve space utilization and worker safety, and route totes to appropriate conveyor for automatic transport between processes. This flexibility comes through a range of configurations: ■ C configuration - Product enters and exits on the same side but at different elevations ■ Z configuration - Product enters and exits on opposite sides ■ T configuration - Product turns at a 90-degree angle, exits perpendicular to the direction of entry ■ X configuration - Product enters and exits on any side uss> An ntelligrated1 Company Intelligrated is now part of Honeywell

Open the catalog to page 1

USS vertical conveyor is well-suited for a variety of applications. Vertical indexing conveyor Vertical indexing conveyor transfers product in a single direction, up or down, with multiple discharge chutes and entry locations for high §§ Accumulation buffering – Control product flow to keep downstream operations moving efficiently system flexibility. Compact designs, efficient timing belt technology and optimized cycle times enable maximum throughput and years of reliable, low-maintenance operation. §§ Kitting – Release totes packed with components to workstations and handle takeaway of...

Open the catalog to page 2All Intelligrated catalogs and technical brochures

-

AS/RS solutions

4 Pages

-

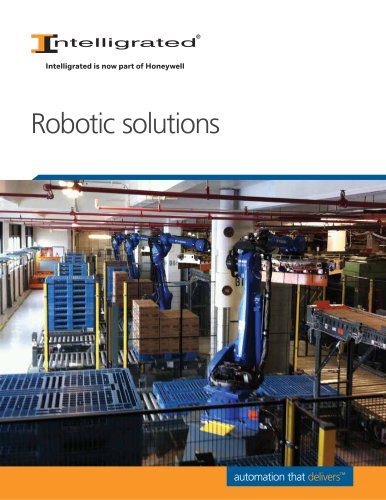

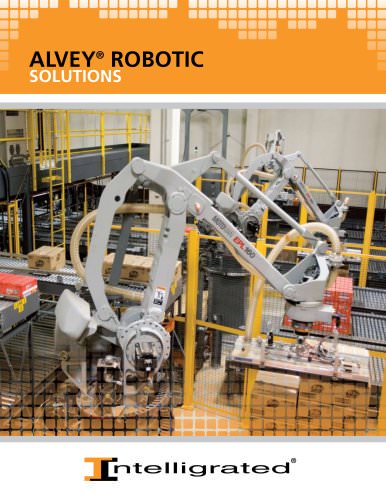

Robotic solutions

8 Pages

-

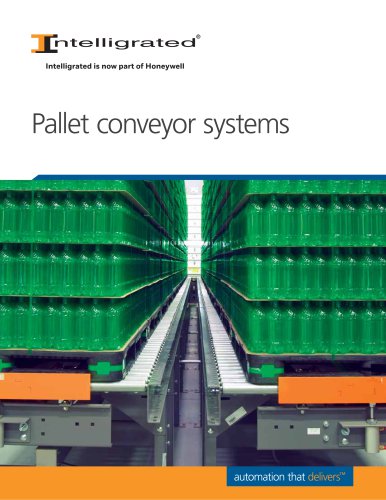

Pallet conveyor systems

8 Pages

-

Corporate Capabilities

28 Pages

-

Alvey Robotic Solutions

6 Pages

-

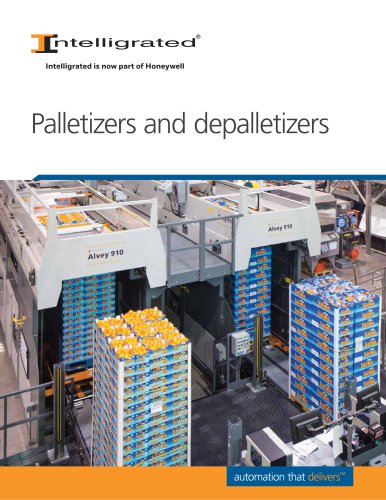

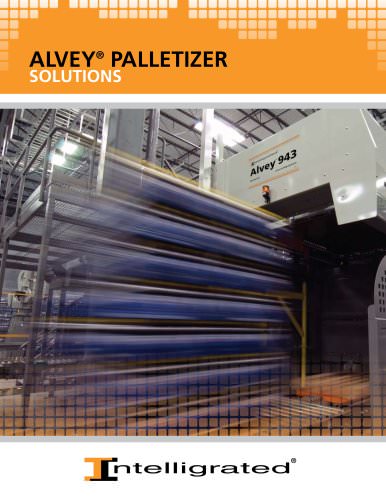

Alvey Palletizer Solutions

6 Pages