Catalog excerpts

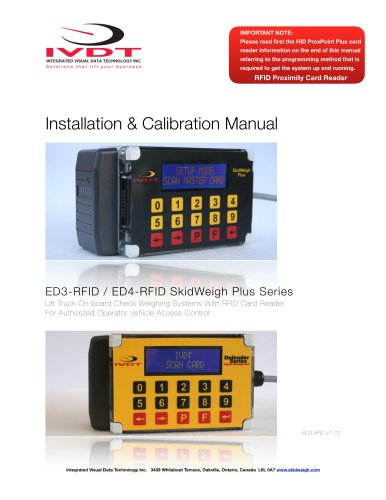

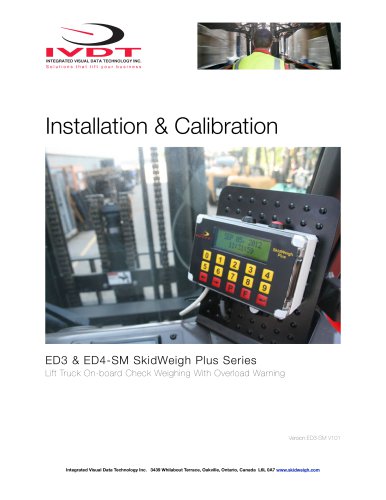

IMPORTANT NOTE: Please read first the HID ProxPoint Plus card reader information on the end of this manual referring to the programming method that is required to get the system up and running. RFID Proximity Card Reader INTEGRATED VISUAL DATA TECHNOLOGY INC. Solutions that lift your business Installation & Calibration Manual ED3-RFID / ED4-RFID SkidWeigh Plus Series _ift Truck On-board Check Weighing Systems With RFID Card Reader =or Authorized Operator Vehicle Access Contro Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville, Ontario, Canada L6L 0A7 www.skidweigh.com

Open the catalog to page 1

General Installation Guide This ED3-RFID and ED4-RFID SkidWeigh Plus V1.12 Series installation & calibration guide describes how to install, calibrate, test and use your on-board check weighing unit. Following the instructions in the ADMINISTRATION MENU guide will enable you to get the system set up and weighing calibration function operating quickly. In the event that you require additional assistance, please contact customer support via e-mail at support@skidweigh.com , visit www.skidweigh.com or contact us at the address or contact number below: Integrated Visual Data Technology Inc....

Open the catalog to page 2

(Master card to be used by the end user to program valid operators RFID cards. All programming can be done with ED3-RFID / ED4-RFID mobile units. There is no need for external programming device ) Operational principal The ED3-RFID SkidWeigh Plus series operational principal is based on the hydraulic pressure transducer mounted in the vehicle lifting hydraulic circuit that will automatically activate the “weighing cycle / specific algorithm ” every time a skid load is lifted just above the ground. The increase in pressure is converted in an electronic signal at the sample rate of 16000...

Open the catalog to page 3

Compact size All of the SkidWeigh systems are compact, housing dimension of only 120 x 80 x 55 mm is ideal for the installations to material handling vehicles of all kinds. Electrical connections All SkidWeigh RFID equipped systems operate from 12 to 55 VDC. Digital indicator with eight wires single cable - Orange Wire (+) Ignition switch On position - Brown Wire (-) Battery negative - Red Wire, connect to RED wire of the pressure transducer cable - Black Wire, connect to BLACK wire of the pressure transducer cable - White Wire, connect to WHITE wire of the pressure transducer cable...

Open the catalog to page 4

IMPORTANT For all SkidWeigh Plus Systems equipped with RFID card reader you MUST HAVE AT LEAST ONE VALID OPERATOR CARD in order to access the administration menu to set up and calibrate the weighing function of the system! “Quick test to determine if electrical connections are done right” Note 1: SkidWeigh weighing calibration function is not done yet at this stage. This procedure is only to test if electrical connections of the system installation into the vehicle is done properly! After you have connected electrical power and pressure transducer cable you can “quickly” check the system...

Open the catalog to page 5

Lift truck equipped with hydraulic accumulators If the standard SkidWeigh system is installed on the lift trucks equipped with hydraulic accumulators, please contact us to provide you with different digital indicator having specific software algorithm to obtain load weight accuracy within +/1% of vehicle maximum lifting capacity. SkidWeigh Plus series ED3-RFID LCD Display RFID Reader Toggle Arrows Keys in set up menu Enter Key Select function in F0 and F9 menu Print key or /and SEND key to wireless base station F9 F0 Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville,...

Open the catalog to page 6

Administration Menu Instructions (Weight scale function calibration, time/date, vehicle ID#) To enter into the Administration Menu, press F9 and input password _____________ Use left and right arrow keys to scroll and follow the LCD instructions. LCD Display MENU PASSWORD = _ LCD Display Date / Time Set Up LCD Display SET CLOCK ENTER TO SELECT LCD Display SET CLOCK AUTO _ Use left and right ▶ arrow key (bottom left side of the keypad) to change from AUTO to MANUAL date/time set up. Note: AUTO set up refers to system utilizing a wireless RF platform with automatic date /time update from IVDT...

Open the catalog to page 7

Aug 28, 2010 12:20:23 Press “Enter key” ↵ to confirm the setting. The cursor will automatically move to the next item to be changed ( Month, Day, Year, Hours, Minutes, Seconds). On the last correction, seconds item press “Enter key” ↵ to confirm new date / time set up. Set vehicle ID Maximum input number for vehicle ID is 4 digits. Note: For system used with RFID card reader maximum input number for vehicle ID is 5 digits. <> KEY to SCROLL F KEY TO EXIT LCD Display SET VEHICLE ID ENTER TO SELECT LCD Display ENTER VEHICLE ID 1_ LCD Display Integrated Visual Data Technology Inc. 3439 Whilabout...

Open the catalog to page 8

USB Port Protective Cover Save data to USB The SkidWeigh Plus system will allow you to download all recorded data onto a USB drive. Follow instructions shown on the LCD display This function is located in Supervisor Menu to protect the integrity of the information. <> KEY to SCROLL F KEY TO EXIT LCD Display SAVE TO USB ENTER TO SELECT LCD Display When the system has finished uploading the data to the USB memory stick the LCD display will prompt you to erase the SDRAM , all files contained on the SKidWeigh Plus ED3-IM . Once you have made your selection Y or N the system will automatically...

Open the catalog to page 9

Weighing scale function calibration The ED3-AT SkidWeigh Plus calibration is automatic and is done by lifting empty and loaded forks (or any other attachment such as paper clamp) just above the ground. MAKE SURE THAT YOU HAVE A KNOWN LOAD WEIGHT AND KEEP IT NEARBY TO COMPLETE THE CALIBRATION. For the best results use at least minimum calibration load test weight of 30 to 50% of maximum lifting capacity of the lift truck. Use customer floor scale or find a known skid load weight within the operational facility. Important: If you want the system to show load weight in pounds, use the known load...

Open the catalog to page 10All Integrated Visual Data Technology Inc catalogs and technical brochures

-

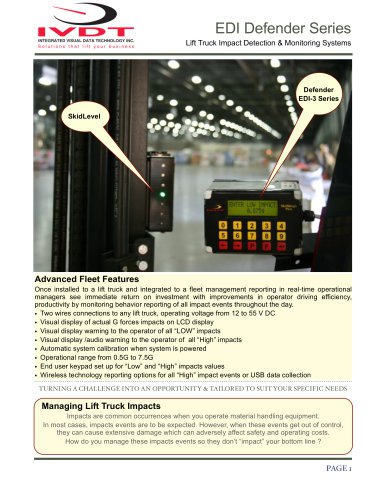

IM2-Defender Series

2 Pages

-

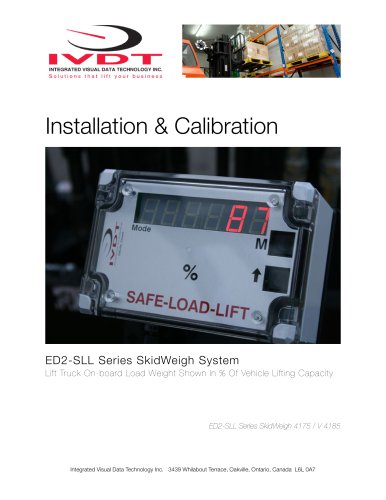

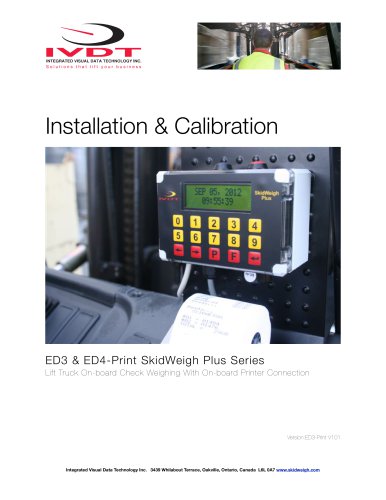

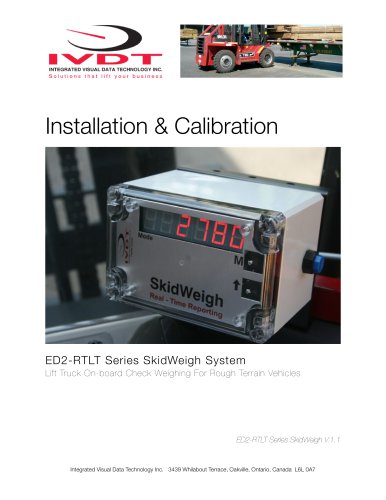

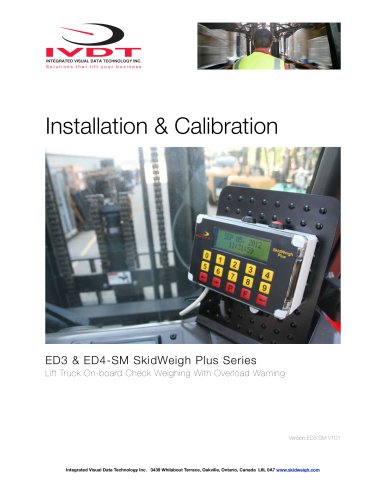

Installation & Calibration

12 Pages

-

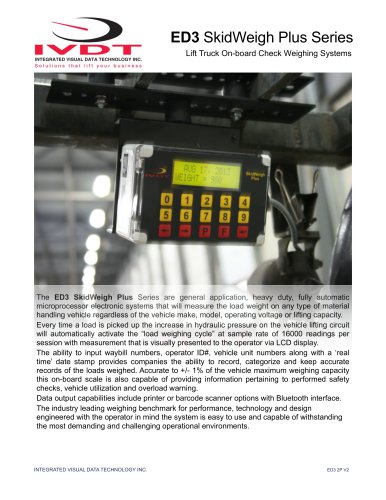

ED3 SkidWeigh Plus Series

2 Pages

-

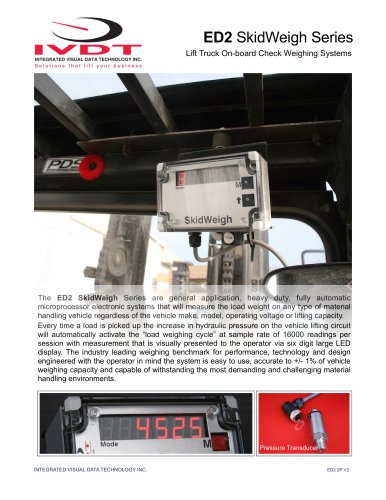

SkidWeigh ED2

2 Pages

-

ED4 SkidWeigh Plus Series

2 Pages

-

ED4 SkidWeigh

10 Pages

-

ED4 SkidWeigh

14 Pages

-

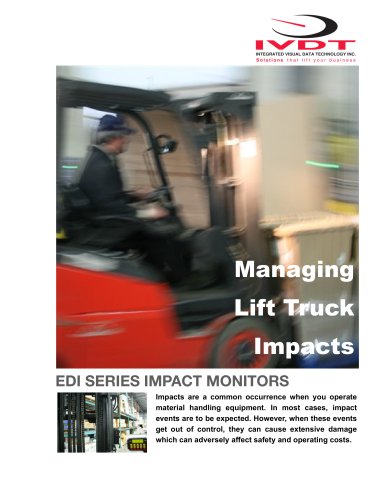

Forklift Impacts detection

14 Pages

-

ED3

14 Pages

-

SkidWeigh Forklift Scale

10 Pages

-

SidWeigh OL Series

11 Pages

-

ED2-EP SkidWeigh

2 Pages

-

Usage SkidWeigh

2 Pages

-

ED3- SkidWeigh Plus-Print

9 Pages

-

ED2-SkidWeigh

2 Pages

-

SkidWeigh printers

4 Pages

-

SP-1000 Series

11 Pages