Website:

Inox Meccanica S.p.A.

Website:

Inox Meccanica S.p.A.

Catalog excerpts

WASHING SYSTEMS INOX MECCANICA TECHNOLOGY

Open the catalog to page 1

A team at your disposal to implement the guidelines through which innovate the washing processes of food equipment. At Inox Meccanica we firmly believe that, to improve technologies related to processes and washing machines and at the same time satisfy the needs and the requirements of the food market, resources, technical potential, specific knowledge and, above all, the ability to “step into the shoes of others” that is in the practical problems of our potential customers. This is why we have promoted the birth of a Team (Washing Solution Team) whose Mission is the constant and...

Open the catalog to page 2

INTRODUCTION The sanitization of environments, production lines and equipment in industries food is now to be considered an integral part of the production process; in fact from one shift to another, it is possible to start again with the production just if all surfaces involved in the production process in contact with food have been sanitized. As well as to be competitive on the market it is essential to innovate to automate and to rationalize the productions, in the same way it becomes more and more urgent to take part on costs and results of sanitation which is an indispensable process...

Open the catalog to page 3

Guarantee of the constant result and Dedicated washing programs and diversified according to the different equipment or products to be washed Less water consumption Electric energy saving washing temperature Savings of detergents products thanks to Wide possibility of system customization an automatic dosing system Technical assistance always ready Cost reduction of water purification to support every need Lower cost of labor and accident risk System easy to wash and sanitize Internally developed software and exclusively by Inox Wide washing flexibility for different equipment or Meccanica...

Open the catalog to page 4

WASHABLE EQUIPMENT… Suitable for all equipment in stainless steel and plastic materials used in the food and non-food industry.

Open the catalog to page 7

SECTORS AND APPLICATIONS We build industrial washing machines designed and engineered with the greatest possible attention to energy saving and water waste without penalizing the washing and sanitizing results. FISH INDUSTRY COSMETIC & PHARMACEUTICAL BAKERY INDUSTRY

Open the catalog to page 8

WASHABLE PRODUCTS... Automatic washing machines for salami, bresaola, hams, speck, etc…! We provide the customer with countless solutions depending on the type of product to be

Open the catalog to page 9

RACKS & TROLLEYS WASHERS It is a specific machine for washing large equipment such as trolleys, frames, tables, cages, etc ... Our washing machine for trolleys can be designed with 1 or 2 doors in order to separate and safely separate dirty equipment from those that have just been cleaned, avoiding contamination. The dimensions and technical characteristics vary according to the equipment to be washed and the rooms in which the machine is installed.

Open the catalog to page 10

CRATES & BOXES WASHERS Specific machine for continuous washing of small and medium-sized containers and crates. The process can consist of several stages depending on customer requirements: pre-washing, washing, rinsing, sanitising, blow-drying, drying. The dimensions and technical characteristics vary depending on the equipment to be washed and the premises where the machine is installed. The crates & baskets washer consists of a washing tunnel, equipped with a conveyor track with adjustable speed.

Open the catalog to page 12

PALLETS WASHERS Machine designed for the continuous washing of pallets and similar used in the meat, dairy and confectionery industry. The fully automatic process ensures the cleaning and disinfection of the containers. Depending on the needs, plants with specific requirements are designed.

Open the catalog to page 14

MOULDS WASHERS This machine has been studied for continuous washing of molds and similar equipment used in the meat, cheese and bakery processing industry. The cycle is completely automatic and guarantees the cleaning and the sanitizing of the containers. According to customer’s need, specific machines are built.

Open the catalog to page 16

BINS & VATS WASHERS Machine designed for washing large containers for the stowage and transport of food products. Designed according to the dimensions of the container to be washed, the washing machine can be produced both in the version with a single door and in the version with the double door in order to keep the product inlet and outlet areas distinct, minimizing contamination.

Open the catalog to page 18

GLOVES, TOOLS & KNIVES WASHERS Conceived and manufactured specifically for washing gloves, slicer knives, pots and containers of various kinds used in the production processes of the food industries. Heating of the washing water with steam, electricity. Very small dimensions despite having a large washing chamber inside. Realization with 1 or 2 workstations.

Open the catalog to page 20

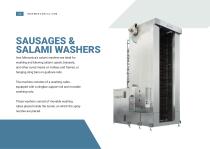

SAUSAGES & SALAMI WASHERS Inox Meccanica’s salumi washers are ideal for washing and blowing salami, speck, bresaola, and other cured meats on trolleys and frames, or hanging sling bars on guidovie rails. The machine consists of a washing cabin, equipped with a slingbar support rail and movable washing rods. These washers consist of movable washing tubes placed inside the tunnel, on which the spray nozzles are placed.

Open the catalog to page 22

THE STRUCTURE HAS BEEN DESIGNED TO GUARANTEE A N E F F E C T I V E C L E A N I N G A N D S A N I T I S AT I O N O P E R AT I O N A F T E R E V E RY W O R K S H I F T

Open the catalog to page 24

REMOTE ASSISTANCE We offer our customers an integrated connectivity system where functionality and ease of use find the perfect balance. Each Inox Meccanica machine can be equipped with a router that allows us to provide timely and often decisive remote support. Our technology can dialogue with production plants and any company management software to offer the best in terms of remote control and in-plant technical assistance.

Open the catalog to page 25

01. MATERIALS The materials used for the construction of ours machines are almost exclusively Aisi stainless steel 304 and plastic materials suitable for corrosive environments. 02. WASHING PUMPS The washing pumps are of the centrifugal type, a open impeller and with Viton seals toresist long to detergent and disinfectants. All machines are equipped with filters at the inlet washing pump, static WHY CHOOSE INOX MECCANICA All the washing machines of INOX MECCANICA are built to last over time, as our customers using our systems for more than 40 years are testifying. for standard systems and...

Open the catalog to page 26All Inox Meccanica S.p.A. catalogs and technical brochures

-

SE-LE net & casing loader

2 Pages

-

IR 115

2 Pages

-

CLP 1T & CLP 2T

2 Pages

-

TUMBLER BT-C

2 Pages

-

TUMBLER BT-S

2 Pages

-

TM 200 V

2 Pages

-

P600 & P800

2 Pages

-

PIC 99 DRW

2 Pages

-

PIC 99 BCE

2 Pages

-

Smoking Sytstem

16 Pages

-

Quality Ham System

24 Pages

-

Fast Ham System

32 Pages