Website:

Inosol

Website:

Inosol

Catalog excerpts

Hydraulic Products innovative solutions Fluid Connectors | Workholdings | Bleed screws Rotary Joints | Valves | Pressure Generators

Open the catalog to page 1

About us... Dear customer, dear prospective customer With this 12th edition of our product catalog we would like to show an overview about our current standard products. The catalog contains products from the fields of fluid connecting and workholding technology, as well as the associated valves, pressure generators, rotary distributors and other accessories. Many of the products we have developed have a real unique selling point. We develop special solutions from the already mentioned areas and especially in the areas of rotary distributors and pressure generators. If you are looking for...

Open the catalog to page 2

Content Workholdings Link Clamps Rotary Lever Clamps Eccentric Lever Clamp Lever Clamp - Tiny Link Clamp 11-15 Sliding Joint Clamp Schwenkspanner Compact Swing Clamp Standard-Swing Clamp Inosol-Swing Clamp Others Work Support up to 350 bar Flat Centering Vise - 200 bar Fluid Connectors Connector Elements, 350 bar Connector Elements, 200 bar Manual Coupling Unit SA Manual Coupling Unit DA Bleeding- and Plug screws Vent/Bleeding Screws Holding Valves 50 Holding Valves Insert Valves Mini Screw-In Valves Mini Pressure Relief Valves Screw-In Non-Return Valve Threaded Valves Hydraulic Timer Valve...

Open the catalog to page 3

Hydraulic Workholdings innovative solutions LINK CLAMPS Rotary Lever Clamp Page 3-7 Eccentric Lever Clamp Page 8-10 Tiny Link Clamp Page 11-15 Sliding Joint Clamp Page 16-17 SWING CLAMPS Compact Swing Clamp Page 18-21 Standard Swing Clamp Page 22-25 Inosol Swing Clamp Page 26-29 OTHERS Work Support Seite 30 Flat Centering Vise Seite 31-35 Examples for custom made solutions: 2 *Subject to change without notice. Current issue under inosol.solutions

Open the catalog to page 4

Rotary lever clamp innovative solutions hydraulic, up to 400 bar, single- and double acting Ü Advantages: üClamping without shear force üCompact design üVery few parts üCost-efficient üLength of clamping arm variable üNo interference contour while loading and unloading üMounting in feeder plate possible Double acting Single acting Because of their compact design, rotary lever clamps are particularly suitable for use in clamping devices with low Installation spaces. The clamping lever is actuated by the piston. Due to the large opening angle of the clamping lever they allow easy loading and...

Open the catalog to page 5

Rotary lever clamp innovative solutions hydraulic, up to 400 bar, single- and double acting Ü Double acting type (Steel) Length - clamping lever (see pages 7+8) Edge rounded Insert contour releasing clamping optional Edge rounded Lateral channel bore View U Control open Control open applies only for type with pneumatic query Control closed Control closed Screws included in scope! Technical Data Part numbers without clamping lever! Effective piston area (cm2) Piston force at 100 bar (kN) Piston force at 400 bar (kN) Volume (ccm) Weight Part number without pneum. query Part number with pneum....

Open the catalog to page 6

Rotary lever clamp innovative solutions hydraulic, up to 400 bar, single- and double acting Ü Single acting type (Steel) Length - clamping lever (see pages 7+8) Z W Edge rounded clamping optional Lateral channel bore View O Single acting type with spring return Y Screws included in scope! Size A B C D E F H J Radius K L M QØ RØ V W X Y (acc. DIN 6912)* Z Effective piston area (cm 2) Piston force at 100 bar (kN) Piston force at 400 bar (kN) Volume (ccm) Weight Part number Technical Data Part numbers without clamping lever! *Subject to change without notice. Current issue under inosol.solutions

Open the catalog to page 7

Rotary lever clamp innovative solutions hydraulic, up to 400 bar, single- and double acting Ü Clamping lever - Standard Part number Calculation Actual Clamping force Fs in response to the piston force FK and Length of lever arm L Example: Rotary lever clamp size 20 working pressure 400 bar, piston force FK = 18 kN Dim. Z (page 3) = 15,0 mm Length of lever L Actual Clamping force Fs = 12,0 kN Clamping force Fs = Attention: On request for size 16-50 there are clamping levers available with a modified operating point. For these ones the clamping length is the same, but the operating point...

Open the catalog to page 8

Rotary lever clamp innovative solutions hydraulic, up to 400 bar, single- and double acting Ü Clamping lever - semifinished Steel (not carbonized) 1.7131 (16MnCr5) Tool steel 1.2842 (90MnCrV8) Part number Steel Part number Tool-steel Attention: Clamping levers from 16MnCr5 must be hardened after mechanical processing! Special levers on Request! Calculation Actual Clamping force Fs in response to the piston force FK and Length of lever arm L Example: Rotary lever clamp size 20 working pressure 400 bar, piston force FK = 18 kN Dim. Z (page 3) = 15,0 mm Length of lever L Actual Clamping force...

Open the catalog to page 9

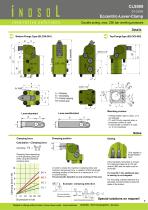

innovative solutions Double acting, max. 250 bar working pressure Ü Advantages: üCompact Design üIncluding Pneumatic Control üTop-Flange- / Bottom-Flange-Models üSimple Counter Contour üThread and manifold connection üVariable Mounting Position The eccentric lever clamp has a relatively high clamping force with a small base area. For this reason, this solution is suitable for machines with high power and challenging spaces. The eccentric lever clamp is a double-acting pressure cylinder, in which the clamping lever is moved over a eccentrically mounted rotary point to clamp the workpiece....

Open the catalog to page 10

innovative solutions Double acting, max. 250 bar working pressure bottom view A = Clamping B = Unclamping P1= Control clamping P2= Control open Mounting contour - If flange bottom type is used, „o“ is not required - P1 and P2 only required when a pneumatic control is used - If only thread connection is used, „w“ is not necessary Notes Clamping position Clamping force Calculation - Clamping force Clamping FK x l1 l2; l3 Only applies to flange-bottom type Clamping force depending on the operating pressure when using the standard clamping lever In order to create the maximum clamping force and...

Open the catalog to page 11