Catalog excerpts

INO MAKINE XP 8000 - 4 AXIS CNC PROFILE MACHINING CENTRE 1 Description: Servo motor 4 Axis CNC controlled Gantry type machining centre, Bridge system supports perfect allignment of the spindle moving on the profile and 0,1mm./1m. Accuracy. Double servo motor system on both sides of the bridge makes the machine work smoothly without any vibration. 7.5 kW high speed spindle works up to 24.000 rpm and is able to work on very thick profiles from the top and all intermediate angles between 0-180 degrees. Perfect CNC Controller provides the most accurate profile machining. The alloys that can be processed on the machine: Aluminium up to 20 mm wall thickness – steel up to 2 mm wall thickness – light alloys such as PVC and etc. The XP 8000 has 8 profile clamps that are manually positioned according to the positions assigned by the CAD-CAM software. AUTOMATIC POSITIONING is optional. All clamps has rigid connection pieces and move on linear guides with bearings. Profile processing in 4 axis is 350 mm. X 350 mm. which is a giant size, compared to the competitors. Thanks to 8 positions tool magazine placed on the side of the machine, it is possible to carry any tool b/w 1 mm – 20 mm tool diameter and 300 mm of disc cutter. The disc cutter is vital for alu windows&doors&sliding series processing. In case the disc cutter i placed in the tool magazine, the magazine capacity falls down to 6 tools. Waste pieces are isolated by the machine cover and extracted by the CE norm waste piece extraction conveyor belt. In this way all the waste pieces are kept in one place and the thee are no waste pieces sticked around the machine. CAD-CAM software is specially designed for the easiest way of processing profiles. The system starts workig with the import of DXF drawings of the profile that will be processed. It is extremely easy to program the profile, make demo before it works, help to work out time study and keep the work done in the HDD of the machine easily. The TWIN working mantality makes the operator to load and offload the profiles without loosing time and it increases the capacity of the machine no less than 5

Open the catalog to page 1

Axis information: X axis net processing length: 6.500mm. – Double Station Y axis net processing width: 350 mm.. Z axis net rpocessing depth: 350 mm. The body: Vibration free steel chasis, processed with the highest accuracy before mounting the linear accessories. Spindle Heads: 7.5 kw 1.000 -24.000 rpm spindle with one inverter adjusted for any rotation speed to work in 4 Axis. Axis technical information: Gantry Type X axis is working on rack and pignon with brushless servo motors and guided by linear guides from the both endings of the bridge with 80 mt./min speed. Servo motors are in...

Open the catalog to page 2

Pneumatic Profile Clamps: 450 mm. X 350 mm. large clamping section. Each clamp’s referance points and the clamping pistons can be removed to adjust the width. Any kind of mould or fixture equipment can be connected easily. Manually positioned. Automatic positioning is optional.

Open the catalog to page 3

Equipment: Referance points: 2 pieces. For using the Machine with 2 processign stations and also for machining profiles longer than the measure. Both endings of the Machine is opened as a standard accessory. Profile clamps: 8 pieces are standard. The number of the clamps can be increased up to 14 clamps optionally. CAD-CAM Software: Uni_Link INO-OnBoard Software – 1 licance for the Machine + 1 licance for the office is included. Laser safety barriers functioning automatically according to the TWIN working cycle. Spray mist cooling system with oil tank mounted on the Z axis. User manuals. CE...

Open the catalog to page 4

INDUSTRIAL CNC CONTROLLER – ESA AOTOMOTION – www.esautomotion.it 12 Axis RTCP (Rotation Tool Center Point) type of 4 Axis simultaniously interpolating real CNC controller. Italian technology with the software and all the hardware. 19” Touchpanel + the CNC controller + the power supply + servo motors + servo drivers with Can-Open. Each axis has “Absolute Encoder” for avoiding the problems caused by homing and home sensors. The Machine does not need to g oto home position each time the operator turns on the Machine. All power & encoder cables, driver mounted motor communication cables and all...

Open the catalog to page 5

Tool Changer Magazine: The capacity is in total 8 places. 8 standard ISO30 or HSK-F63 tool holders + 1 disc cutter with maximum diameter of 300 mm. Placed inside the Machine cover, in front of the spindle not to loose time during the tool change. Maximum disc cutter diameter 350 mm. Maximum tool size 200 mm. Magazine cover pneumatically openning and closing to keep the tools clean from swarf. Optional: Bigger tool changing magazine for 11 tool places.

Open the catalog to page 6

Air Cooling electrospindle: High speed spindle with ceramic bearings. Standard ISO 30; optionally HSK F-63 Air cooling system. Spindle Power: 7.5 kW in S6 and 6.6 kW in S1 Spindle Torque: 5.9 Nm in S6 and 5.3 kW in S1 Spindle rotation: 24.00 rpm (adjustable between 0-24.000) Tool Holder Set - Optional Collet Set - Optional Cutter set - Optional Liquid Cooling electrospindle: High speed spindle with ceramic bearings. Standard HSK F-63 Liquid cooling system thanks to chiller placed beside the Machine. Spindle Power: 10.0 kW in S6 and 8.5 kW in S1 Spindle Torque: 8.0 Nm in S6 and 6.8 kW in S1...

Open the catalog to page 7

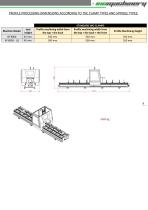

PROFILE PROCESSING DIMENSIONS ACCORDING TO THE CLAMP TYPES AND SPINDLE TYPES: Profile machining width from the top + the back 350 mm. 500 mm. STANDARD INO CLAMPS Profile machining width from the top + the back + the front 350 mm. 500 mm. Profile Machining Height 350 mm. 350 mm.

Open the catalog to page 8

UNI_LINK 3D CAD-CAM: • Design, R&D and application are carried through the vast experinece of ino machinery team and Uni_Link engineers. • The perfect optimization of economic profile working in 3,4 and 5 Axis. • Importing of DXF files and converting them to 3D images. • Generating G-codes over the DXF files. • Understanding of the operations on the DXf files and auto-tooling • Also availbale in Office verson with a perfect simulation interface, so that the one working at the Office will also prepare the profile machining programs just like he is beside the machine. • Incredibly user...

Open the catalog to page 9