Catalog excerpts

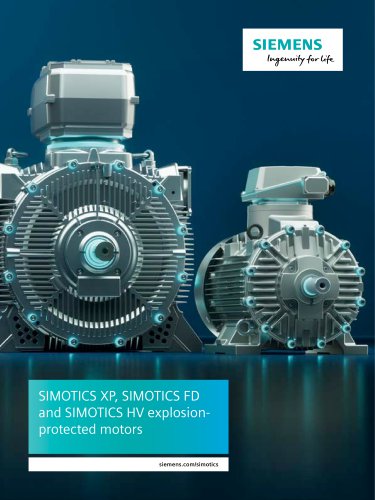

Please scan the QR code for further information The SIMOTICS HV family siemens.com/simotics-hv Motors for every demand Core Applications and Product Highlights Core Applications Pumps, fans, blowers, compressors, extruders, agitators, mixers, mills, crushers, kilns, conveyor belt systems, t hrusters, winches, refiners, winders etc. Core Applications Pumps, fans, blowers, compressors, extruders, agitators, mixers, mills, crushers, kilns, conveyor belt systems, t hrusters, winches, refiners, winders etc. Maximum plant availability, low operating cost, short time to market SIMOTICS HV Series H-compact Product Highlights Revolutionary cooling concept – Unique power density for minimum space requirements and easy plant integration. There are good reasons why the SIMOTICS HV family is one of the leading portfolio in the global transnorm motor market. The comprehensive portfolio has the optimum motor for every high-rating drive application and sets new standards when it comes to flexibility, efficiency, time to market and plant availability. The backbone of your process reliability We know about the importance of our motors for the reliability of your plant and application. That’s why we put every effort into quality and testing. The result: an optimized performance, and reliability and availability second to none, also in extreme environments. In addition the use of highly standardized com‑ ponents increases plant availability through simplified spare parts management. And: SIMOTICS HV motors are now integral part of SIDRIVE IQ, the digital platform for optimizing your drive systems. Thus SIMOTICS HV motors take advantage of digitalization to enter into a new dimension of availability, serviceability, productivity, and efficiency. Maximum flexibility Our motors are available in virtually any imagi ble configurana tion and offer power ranges up to 100 MW and higher, speeds from 7 to 15,900 rpm and torques up to 2460 kNm. When you select your transnorm motor from our HV motor lineup, you gain considerable flexibility. This includes several cooling systems and degrees of protection as well as suitability for use in aggressive atmospheres and in potentially hazardous areas. Extremely rugged design – Maximum reliability even under extreme conditions Optimized temperature distribution – Extended service intervals and extreme long ifetime l Variable terminal box position – Increased flexibility in plants and systems and simplified installation Energy usage has an especially significant impact on the operating costs. To keep these low, SIMOTICS HV motors have an especially low-loss design: in some instances, they have efficiencies close to 99%. Beyond this, the low-maintenance concept reduces maintenance costs to a minimum. Product Highlights Compact construction concept – Low space requirements and low weight for easy plant integration. Optimum efficiency – Low operating cost Designed for a high degree of reliability – High plant availability and low service & maintenance cost Low noise level – Exceeds most customer and legislated safety requirements Minimized noise level – Reduced noise damping measures and costs on-site SIMOTICS HV M Core Applications Compressors, pumps, fans, blowers, extruders, agitators, mixers, mills, crushers, kilns, thrusters, main propulsion, refiners, rolling mills etc. Product Highlights Highest power density – Small dimensions and low weight for simplified handling and easier plant integration. High stiffness design – Higher reliability and lower v ibrations, even under extreme conditions Very flexible construction concept – Accurately fitting solutions for the individual applications Short delivery times and standardized engineering tools – Simplified selection and configuration, shorter time to market Noise damping design – Less noise emission and in compliance with governmental laws Special motors for wide speed range (sub-critical motor design) Shorter project execution times SIMOTICS HV helps you cut on lead times with standardized production and test processes. The integration into standard tools such as Drive Technology Configurator shortens project planning times, and the tools also supports in configuring system components. How ver, SIMOTICS HV motors theme selves play a role in signifi antly speeding up project c execution: Their delivery times are extremely short and their small dimensions and low weight for the particular power rating, coupled with the installation- riendly design means that f they can be very quickly integrated in the plant or system. SIMOTICS HV Series A-compact PLUS Core Applications Pumps, fans, blowers, compressors, conveyors, main propulsion, thrusters Product Highlights Focused on features essential for high power, pumps and compressors – Low lifecycle cost by proven quality. Rugged design, low wear materials – Reliable and long service lifetime Extremely compact design – Low space requirements, easy plant integration SIMOTICS HV compact motors Subject to changes and errors. The information given in this document only contains general descriptions and/or performance features which may not always specifically reflect those described, or which may undergo modification in the course of further development of the products. The requested performance features are binding only when they are expressly agreed upon in the concluded contract. Article No.: PDLD-Y10129-01-7600 Dispo 00000 MD 000-000000 © Siemens 2021 Siemens Industry Inc. 100 Technology Drive Alpharetta, GA 30005 United States For the U.S. published by Large Drives Applications Vogelweiherstr. 1–15 90441 Nuremberg Germany Published by Siemens AG Trust every choice. SERENITY. SECURITY. SIDRIVE IQ LARGE DRIVES APPLICATIONS siemens.com/sidrive-iq SIDRIVE IQ – the holistic solution and service to IIoT for your drive system • Shorten unplanned downtimes • Increase availability • Reduce service and maintenance costs • Boost your productivity The goal of SIDRIVE IQ is to: Condition data such as drive information, historic logs, parameters and fault logs are evaluated, processed and sent to our cloud for analysis. In addition to that it can be analyzed with our digital platform SIDRIVE IQ Suite. With SIDRIVE IQ Suite users can track and visualize various drive system conditions, show trends, error messages and generate reports. SIDRIVE IQ is an integral component of SINAMICS drives. SINAMICS drives are equipped with a connectivity module (SINAMICS CONNECT 500) so that they can be easily integrated into our digital, cloud-based solution. SIDRIVE IQ – our holistic solution and service to IIoT for drive systems SIMOTICS HV modular motors Flexible regarding number of poles, voltage and cooling concept – Accurately fitting solutions for the individual application SIMOTICS HV high-power motors High-quality coating systems – High availability even under rough environment conditions SIMOTICS HV HP Core Applications High-power compressors for pipelines. LNG or air separation, IGCC compressors, large pipeline pumps, boiler fed pumps, blast furnace blowers, high-power mixers and extruders, high-power refiners etc. Product Highlights Unique grade of modularity and adaptability – Tailor-made solutions also for a wide range of complex high-power applications. Optimized baseframe – High mechanical rigidity, low vibrations, low noise and noise protection Standardized interfaces – Fast implementation Largely standardized components – Increased plant vailability due to fast and easy a access to spare parts and optimized serviceability Efficiency rates of close to 99% – Low operation cost Core Applications High-speed compressor drives, injection pumps, rolling mills, mine hoists, mine winders, direct-driven conveyor systems, gearless ring drives for ore mills, gearless drives for excavators etc. Product Highlights Specifically optimized to meet specific requirements of very complex applications – Tailor-made solutions also for extraordinary demands. Motor Solutions with extreme low speed (7 rpm), high speed (15,900 rpm) and high torque up to 40,000 kNm are available – Almost no limits concerning speed and torque Motor power ratings of 100 MW and more are possible – Perfect solutions for applications such as all electric LNG plants SIMOTICS HV ANEMA Core Applications Compressors, pumps, fans, blowers, extruders, agitators, mills, crushers, kilns, conveyor belt systems, thrusters, winders, main propulsion, refiners, winders, rolling mills etc. Product Highlights Tailored to the customers specifications – Reduced ngineering time and increased reliability. e Maximum availability and efficiency – Low total cost of ownership Rugged and low maintenance – Maximum productivity due to minimum downtimes. Perfect fulfilment of all NEMA specifications – Tailor- ade motor solution for the American market m Wide range of direct drive solutions – For va

Open the catalog to page 1All INNOMOTICS catalogs and technical brochures

-

Y87

1 Pages

-

SINAMICS CU320 control unit

2 Pages

-

K86

2 Pages

-

SINAMICS PERFECT HARMONY GH180

90 Pages

-

D02

2 Pages

-

D03

2 Pages

-

D04

2 Pages

-

D021

2 Pages

-

E9x

4 Pages

-

K51

1 Pages

-

P61

2 Pages

-

Innomotics Training Services

4 Pages

-

NXGPro+

2 Pages

-

A02

2 Pages

-

SISynch

5 Pages

-

High Voltage Motors HV C

572 Pages

-

Medium Voltage Drives GM150 SM150

202 Pages

-

SINAMICS S200

156 Pages

-

SINAMICS S210

476 Pages

-

SIMOTICS Motors for Cranes

118 Pages

-

SINAMICS G220

112 Pages

-

SINAMICS Low Voltage Converters

34 Pages

-

SIMOTICS low-voltage motors

36 Pages

-

SC600 and SIDRIVE IQ

8 Pages

-

DC motors

44 Pages