Catalog excerpts

SIMOTICS – compact, dynamic and rugged The optimum motor for every motion control application

Open the catalog to page 1

SIMOTICS motion control -if you want to move something 3 Optimum integration in the drive and control system 4 Servomotors for every motion application 5 Our servo drive systems -can be simply engineered for your application 11 Main motors with outstanding performance up to 40,000 rpm 13 The benchmark for directly driving linear axes 16 Always providing the right spin at precisely the right time 18 MOTION-CONNECT connection system -the simple, fast and reliable connection 20 DRIVE-CLiQ - for plug & play commissioning and increased transparency for monitoring motors 21 SIZER, DT Configurator...

Open the catalog to page 2

Since the development of the dynamo-electric principle by Werner von Siemens back in 1866, innovative motor technology represents a core business of our company. In addition to low-voltage, DC and high-voltage motors, SIMOTICS motion control motors have firmly established themselves in many sectors when it comes to addressing demanding motion control applications. The correct solution Whether for precise and repeatable positioning, constant speed and high dynamic motion, long traversing paths or fast velocity changes - the Siemens SIMOTICS portfolio of servo, main, linear and torque motors...

Open the catalog to page 3

Optimum integration in the drive and control system Our SIMOTICS motion control motors are perfectly harmonized and coordinated for operation with our SINAMICS frequency converters. This simplifies engineering and commissioning system solutions for high-performance applications in plant and machinery construction. To optimize interaction with the converter, the motors have a DRIVE-CLiQ interface to quickly transfer data – and transparently monitor important motor data. Further, SIMOTICS motion control motors operate perfectly with SIMATIC, SINUMERIK and SIMOTION control systems from...

Open the catalog to page 4

Servomotors for every motion application No matter whether positioning, angular synchronism, cyclic drives or path control in machine tools: With SIMOTICS servomotors you profit from high dynamic performance, precision, compactness and ruggedness. SIMOTICS S-1FK7 – cost-effective, flexible and universal With our SIMOTICS S-1FK7 servomotors, depending on the requirements relating to dynamic performance, control response, precision and space, there are three moment of inertia versions to select from – when required, also in combination with a gearbox. SIMOTICS S-1FK7 Compact (CT) High power...

Open the catalog to page 5

Servomotors for every motion application SIMOTICS S-1FK7 High Inertia (HI) The increased intrinsic moment of inertia of our SIMOTICS S-1FK7 High Inertia (HI) motors ensures an extremely rugged control response, ideal for applications with high and variable load moments of inertia. SIMOTICS S-1FK7 with mounted planetary gearbox When specified, we can also supply S-1FK7 motors with a mounted planetary gearbox. High-precision and economic planetary gearboxes are available to address a wide range of applications. You profit from high smooth running properties and compactness for motion control...

Open the catalog to page 6

Servomotors for every motion application SIMOTICS S-1FT7 – maximum power and performance with customized cooling Our SIMOTICS S-1FT7 motors are completely in their element when it comes to high-performance motion applications in the torque range up to 280 Nm. They are available in two different versions with various cooling methods: SIMOTICS S-1FT7 Compact motors (CT) Naturally cooled, force-ventilated or water-cooled 1FT7 motors are predominantly used where space is restricted and a high power density is required. Their low torque ripple makes them predestined for machine tool applications...

Open the catalog to page 7

Servomotors for every motion application Forced ventilation Natural cooling Typical application areas • Machine tools • Packaging machines • Printing machines • Conveyor technology and handling systems SIMOTICS S-1FT7 servomotors - an overview SIMOTICS S-1FT7 * depending on the version and type

Open the catalog to page 8

Servomotors for every motion application SIMOTICS S-1FG1 – open for a wide range of gearboxes The concept of our SIMOTICS S-1FG1 servo geared motors is attractive as a result of the variable configuration options that can be used to create customized solutions both regarding type of construction and power rating. Irrespective of whether your application requires a helical, parallel shaft, bevel or helical worm gearbox: With high efficiencies, low torsional backlash and finely graduated ratios, these motors can optimally address a wide range of different motion control applications. Optimum...

Open the catalog to page 9

Servomotors for every motion application Helical geared motor Parallel shaft geared motor Bevel geared motor Helical worm geared motor Typical application areas • Packaging machines • Printing machines • Wood and metal processing • Palletizers and storage & retrieval machines with hoisting, gantry and fork drives • Dosing pumps and actuator drives SIMOTICS S-1FG1 servo geared motors – an overview SIMOTICS S-1FG1 Helical geared motor 2-stage (Z), 3-stage (D) Parallel shaft geared motor 2-stage (Z), 3-stage (D) Bevel geared motor, 2-stage (B), 3-stage (K) Helical worm geared motor, 2-stage...

Open the catalog to page 10

Highlights SINAMICS V90 and SIMOTICS S-1FL6 • Two versions with different moments of inertia: Low and High Inertia • Three hundred percent overload capability and high IP65 degree of protection • With either incremental or absolute encoder • Quick release connector for simple motor installation • Servo tuning and machine optimization using the auto-tuning function • All frame sizes have an integrated braking resistor • Optional with/without brake -as well as with plain shaft or feather key can be flexibly configured in the lower power range In conjunction with SINAMICS V90 inverters, our...

Open the catalog to page 11

Our servo drive systems can be simply engineered to address your application Highlights SINAMICS S210 and SIMOTICS S-1FK2 • Two versions with different moments of inertia: Compact and High Dynamic • High efficiency and 300 percent overload capability • With either multiturn absolute or incremental encoders • Extremely simple to commission with web server, motor parameters are automatically read in - and the drive system can be perfectly optimized using the One Button Tuning function • One Cable Connection (OCC) to connect the motor to the converter SIMOTICS S-1FK2 and SINAMICS S210 -perfect...

Open the catalog to page 12All INNOMOTICS catalogs and technical brochures

-

Y87

1 Pages

-

SINAMICS CU320 control unit

2 Pages

-

K86

2 Pages

-

SINAMICS PERFECT HARMONY GH180

90 Pages

-

D02

2 Pages

-

D03

2 Pages

-

D04

2 Pages

-

D021

2 Pages

-

E9x

4 Pages

-

K51

1 Pages

-

P61

2 Pages

-

Innomotics Training Services

4 Pages

-

NXGPro+

2 Pages

-

A02

2 Pages

-

SISynch

5 Pages

-

High Voltage Motors HV C

572 Pages

-

Medium Voltage Drives GM150 SM150

202 Pages

-

SINAMICS S200

156 Pages

-

SINAMICS S210

476 Pages

-

SIMOTICS Motors for Cranes

118 Pages

-

SINAMICS G220

112 Pages

-

SINAMICS Low Voltage Converters

34 Pages

-

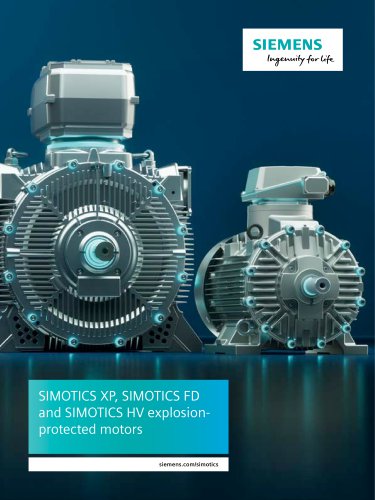

The SIMOTICS HV family

7 Pages

-

SIMOTICS low-voltage motors

36 Pages

-

SC600 and SIDRIVE IQ

8 Pages

-

DC motors

44 Pages