Catalog excerpts

Optical Identification SIMATIC MV - Keeping a watchful eye on production and logistics

Open the catalog to page 1

Optical Identification: a watchful eye on production and logistics As automation rapidly advances, the demands placed on industrial identification are steadily growing. Siemens’ response to these requirements is SIMATIC Ident, a uniquely comprehensive and scalable portfolio of RFID and optical read systems for the flexible implementation of efficient, economical identification solutions in manufacturing and logistics. SIMATIC Ident is the top choice for meeting today’s requirements and one of the key technologies on the road to digitalization

Open the catalog to page 2

Identification systems: optical readers and RFID Whether Data Matrix Codes (DMC) or radio frequency identification (RFID): Both marking and recognition systems feature high data security, have been proven in a variety of applications - including in harsh industrial environments - and meet the growing demand for seamless tracking and tracing of products and processes. At the same time, they require less time and effort than manual marking and reading systems. For the precise reading and verification of 1D/2D codes, text recognition (Optical Character Recognition, OCR), and object...

Open the catalog to page 3

The future is in the cloud – SIMATIC MV500 supplies production data to MindSphere Maintaining a constant overview of the entire production and supply chain means dealing with staggering volumes of data that flow together into virtual clouds to the Internet of Things (IoT). The analysis and utilization of this data opens up unimagined potential. Siemens has developed a solution that allows this potential to be fully exploited. MindSphere supports the digital transformation of enterprises of any size and in any sector, and in the shortest possible time. Embrace the digital future with SIMATIC...

Open the catalog to page 4

Example applications Optical Identification in practice Pick & place: random picking of product blanks by robots Industry: any Detecting the position of product blanks for pick & place by means of robots • Reading of workpiece position, detection and ejection of defective parts • Communication of position of correct workpieces to robots Solution • Transportation of workpiece to processing position when this position is free • Large image field – one camera precisely covers the entire range • High processing speed for complex structures • Reduced glare thanks to flexible lighting Benefits •...

Open the catalog to page 6

Verification: checking of marking quality in the supply and production chain Industry: automotive supplier Measuring marking quality according to supplier specifications • Testing stations in the production and delivery chain according to applicable standards, such as ISO TR 29158 • Checking and documentation of markings for readability • Implemented test algorithms and calibratable lighting units according to standard • Large high-resolution image sensors according to standard • Trend information via uncalibrated Q-measurement • Product includes test algorithms and calibration card •...

Open the catalog to page 7

More example applications Routing: recording of product ID to control transport systems Industry: Food & Beverage, Pharma, Tobacco Controlling transport systems (routing) based on product ID • Flexible reading of ID for different products • Selective activation of transport system for the specific product Solution • Control of highly flexible logistics processes, for example to perform specific product picking • Large image field – with extreme accuracy • High image capture rate and high processor performance ensure extremely high belt speed • Flexible, high-performance IP67 built-in ring...

Open the catalog to page 8

Assembly: detection of installation status Industry: automotive Ensuring correct built-in parts by measuring slight differences in shape SIMATIC MV440 • Checking the correct position of an installed element using the optical reader, based on preceding assembly stage • Alternatively: checking a product property before an assembly stage as prerequisite for the next step • Preventing the installation of damaged and/or semi-finished products and protecting production plants against damage • Large image field for large objects • E-focus for simple commissioning and distances from product •...

Open the catalog to page 9

0 Everything necessary for Marking, Verifying, Reading, and Communication Four key elements are required for Direct Part Marking (DPM) traceability applications that we combined under MVRC: Marking, Verification, Reading, and Communication. Marking is placing the code directly on the object, verification is checking the quality of the mark located on the object, reading is reading the mark in the production domain or when servicing, and communication is reliably transmitting the read result. Siemens covers all four key elements with a variety of products and systems and provides support for...

Open the catalog to page 10

Marking Applying the code directly to the object (DPM) Verifying Checking the quality of the mark located on the object Reading Reading the mark in the production domain or when servicing Communication Transmitting the read results

Open the catalog to page 11

Optical readers The SIMATIC MV optical readers are high-performance, intelligent readers both for easy, high-contrast 1D/2D codes and for difficult-to-read DPM codes on different surfaces on the product itself. The optical readers also permit text recognition, object recognition, and the checking of marking quality. Readers in the SIMATIC MV family also feature high-performance image capture. Different resolutions and integrated lighting thus make the optical readers the obvious choice for flexible use in production and logistics. Device configuration via Web-Based Management and system...

Open the catalog to page 12

AutoTrigger With AutoTrigger, codes that enter the reader's image field are automatically read. The reader itself searches a sequence of images over any preferred time span for code visibility. It does not require any external trigger signals, such as from a light barrier. Multi-code reading With multi-code reading, up to 150 codes can be coded for each image capture, for example when several objects are bulk-read in one stack. Verification Only high-quality marking can ensure maximum readability in the case of contamination in the production proczes. Verification also reduces production...

Open the catalog to page 13All INNOMOTICS catalogs and technical brochures

-

Y87

1 Pages

-

SINAMICS CU320 control unit

2 Pages

-

K86

2 Pages

-

SINAMICS PERFECT HARMONY GH180

90 Pages

-

D02

2 Pages

-

D03

2 Pages

-

D04

2 Pages

-

D021

2 Pages

-

E9x

4 Pages

-

K51

1 Pages

-

P61

2 Pages

-

Innomotics Training Services

4 Pages

-

NXGPro+

2 Pages

-

A02

2 Pages

-

SISynch

5 Pages

-

High Voltage Motors HV C

572 Pages

-

Medium Voltage Drives GM150 SM150

202 Pages

-

SINAMICS S200

156 Pages

-

SINAMICS S210

476 Pages

-

SIMOTICS Motors for Cranes

118 Pages

-

SINAMICS G220

112 Pages

-

SINAMICS Low Voltage Converters

34 Pages

-

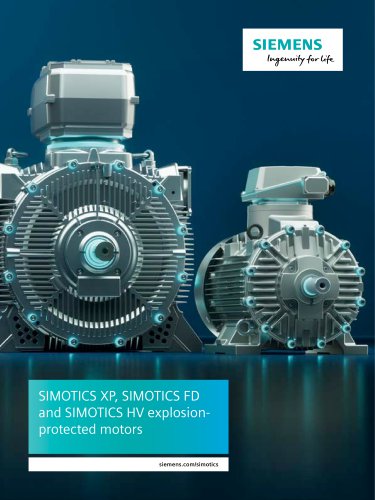

The SIMOTICS HV family

7 Pages

-

SIMOTICS low-voltage motors

36 Pages

-

SC600 and SIDRIVE IQ

8 Pages

-

DC motors

44 Pages