Catalog excerpts

Motors High Voltage Three-phase Induction Motors SIMOTICS HV Series A-compact PLUS

Open the catalog to page 1

Related catalogs Three-Phase Induction Motors SIMOTICS HV, SIMOTICS TN Series H-compact PDF (E86060-K5584-A111-A8-7600) Three-Phase Induction Motors SIMOTICS HV M

Open the catalog to page 2

High Voltage Three-phase Induction Motors SIMOTICS HV Series A-compact PLUS Motors Introduction Overview Technical features Article number code Type selection Overview of bearing versions Overview of explosion-protected motors Conveyor applications Options Motors for operation on line or with SINAMICS PERFECT HARMONY converters Open-circuit cooled motors Air/air-cooled motors Air/water-cooled motors Marine versions Selection and configuration tools Service & Support Catalog D 84.9 · 2019 Supersedes: Catalog D 84.9 · 2015 © Siemens AG 2019 The products and systems described in this catalog...

Open the catalog to page 3

Technical features Terminal boxes Vibration Article number code Type selection Overview of bearing versions Overview of explosion-protected motors Classification of zones Conveyer applications Options Description of options

Open the catalog to page 5

Introduction Overview ■ Overview SIMOTICS HV Series A-Compact PLUS high voltage motors The SIMOTICS HV Series A-compact PLUS high voltage motors are a new generation of modular motors manufactured by Siemens Electrical Drives Ltd., Tianjin, China. These motors have a high degree of reliability and are very compact. They are suitable for a wide range of applications, e.g. pumps, fans, compressors. The motors’ high availability still applies when used indoors, outdoors and even in regions with rough climates – as well as at high altitudes and in areas with a high humidity. Basic information •...

Open the catalog to page 6

Introduction Overview ■ Overview (continued) Open-circuit cooling Great performance in a compact design SIMOTICS HV Series A-compact PLUS The development of the A-compact PLUS series was focused on achieving the highest degree of reliability and lowest envelope dimensions. As a result, the A-compact PLUS high voltage motor fulfills both of these requirements: Reliable power and compact design. A-compact PLUS motors are designed for highly reliable operation of standard applications. Simplified order and optimized production processes result in considerably shorter delivery times. This...

Open the catalog to page 7

Introduction Technical features Terminal box Overview of generally used main terminal boxes Max. equipment mounting height 40 mm

Open the catalog to page 8

Introduction Technical features Terminal boxes ■ Dimensional drawings Main terminal box 1XB1 631 554

Open the catalog to page 9

Introduction Technical features Terminal boxes ■ Dimensional drawings (continued)

Open the catalog to page 10

Introduction Technical features Terminal boxes ■ Dimensional drawings (continued)

Open the catalog to page 11

Introduction Technical features Vibration ■ Overview High vibration quality An innovative production process in conjunction with high-precision balancing results in the vibration severity grade A (2.3 mm/s) according to IEC 60034-14. Environment-friendly low noise levels These motors have low noise values - even in the basic version. This has been achieved as a result of the following: • Optimum mechanical design of the motor • Motor frame and end shields made of grey cast iron for high damping • Optimized cooling • Aerodynamically designed fan • Air intake and enclosure designed for low...

Open the catalog to page 12

Introduction Article number code ■ Overview Structure of the Article No.: Safe area motors 1st to 2nd position: Main Group Identification 3rd position: 4th position: Series 5th to 6th position: Shaft height in mm according to horizontal machine 7th position: Core length Explosion-protected motors ' Safe area (1R...) • Squirrel cage - open cooling circuit ODP/WPI (IP23 / IC01) • Squirrel cage - air/water cooling TEWAC (IP55 / ICW81) • Squirrel cage - open cooling circuit WPII (IP24 / IC01) • Squirrel cage - air/air cooling TEAAC (IP55 / IC611 or IC616) Explosion-protection (1S...) • Squirrel...

Open the catalog to page 13

Introduction Article number code ■ Overview (continued) Structure of the Article No.: 10th position: Rotor winding for line supply and converter fed operation 11th position: Voltage and frequency 12th position: Type of construction • 4.16 kV, 60 Hz • 4.0 kV, 60 Hz • 2.3 kV, 60 Hz • 6.0 kV, 50 Hz • 6.6 kV, 50 Hz • 10 kV, 50 Hz • Other voltage/frequency • Horizontal (IM B3) • Vertical (IM V1) with protective hood • Horizontal (IM B35) with IEC flange and feet • Vertical (IM V1) without protective hood Additional information as text and/or option code required. Other voltage/frequency...

Open the catalog to page 14

Introduction Type selection Basic considerations when selecting a motor • Ambient conditions: Temperature, moisture, altitude • Type of driven load and moment of inertia • Starting frequency and voltage drop • Duty type and other special requirements • Temperature rise • Direction of rotation • Sort of coupling • Position of the terminal box The influence of ambient temperature and altitude on power rating 1RA1/1RP1 Guideline for coupling selection • The A-compact PLUS motors are designed for operation with a flexible coupling. • Motor and driven machine have to be aligned according to...

Open the catalog to page 15

Introduction Overview of bearing versions ■ Overview Bearing version Motors for connection to the line supply have anti-friction bearings or sleeve bearings as standard according to the following overview. The bearing concepts for motors for converter operation depend on the speed control range. Overview, bearing versions For motors with sleeve bearings, lateral flanges are used. Generally, these motors are equipped with two floating bearings. This means that the rotor must be axially guided by the bearings of the driven machine through a coupling with limited axial play. An appropriate...

Open the catalog to page 16

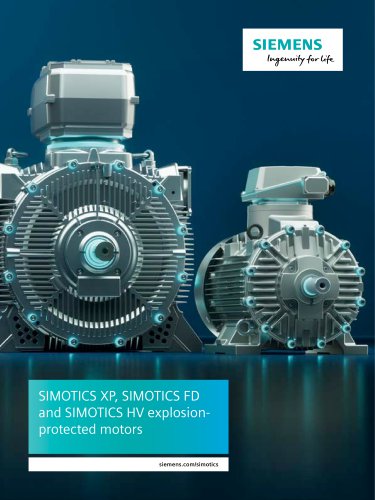

Introduction Overview of explosion-protected motors ■ Overview In many industries, the manufacture, processing, transport or storage of combustible materials results in the creation or release of gases, vapors or mist into the environment. Combustible dusts are created in other processes. Explosive atmospheres are formed when gases, vapors, mist or dust come into contact with oxygen in the air. If ignited, this can result in an explosion. In the chemical and petrochemical industries in particular, when crude oil and natural gas are transported, or in mining, milling (e.g. grain and granular...

Open the catalog to page 17All INNOMOTICS catalogs and technical brochures

-

Y87

1 Pages

-

SINAMICS CU320 control unit

2 Pages

-

K86

2 Pages

-

SINAMICS PERFECT HARMONY GH180

90 Pages

-

D02

2 Pages

-

D03

2 Pages

-

D04

2 Pages

-

D021

2 Pages

-

E9x

4 Pages

-

K51

1 Pages

-

P61

2 Pages

-

Innomotics Training Services

4 Pages

-

NXGPro+

2 Pages

-

A02

2 Pages

-

SISynch

5 Pages

-

High Voltage Motors HV C

572 Pages

-

Medium Voltage Drives GM150 SM150

202 Pages

-

SINAMICS S200

156 Pages

-

SINAMICS S210

476 Pages

-

SIMOTICS Motors for Cranes

118 Pages

-

SINAMICS G220

112 Pages

-

SINAMICS Low Voltage Converters

34 Pages

-

The SIMOTICS HV family

7 Pages

-

SIMOTICS low-voltage motors

36 Pages

-

SC600 and SIDRIVE IQ

8 Pages

-

DC motors

44 Pages