Catalog excerpts

Shaft vibration monitoring for sleeve bearings Order option A02 1 Description Using sensing probes, the shaft vibration monitoring continually senses the shaft vibration at the bearing locations. If vibration values change with respect to normal operation, the machine can be specifically monitored or shut down. As a consequence, problems are identified at an early stage and damage avoided. Vibration values are influenced by the bearing condition, the balance state and the machine mounting; they are also influenced by vibration excited by the driven machine via the drive shaft or from the line supply to the motor. The measuring circuit comprises the ”probe”, which is connected to the ”proximitor sensor” signal converter. A ”proximitor sensor” is integrated in a protective enclosure and is directly connected with the contactless probe (measuring sensor) at the end of a protective tube. It is attached to the machine through a thread and an adapter in the bearing housing or at the bearing sealing bracket. The signal converter output is wired to an auxiliary terminal box. Suitable evaluation units can be connected to series terminals at this interface. The probe senses the distance to the shaft. 2 vibration monitoring devices are attached to each sleeve bearing to sense the shaft vibration in two dimensions. They are arranged at an angle of ±45° with respect to the vertical, and are located in one plane perpendicular to the shaft. Shaft vibration is determined by evaluating the induced voltage change. The voltage change is proportional to the change in distance (clearance to the shaft). Mounting, shaft vibration monitoring, example Proxpac XL, Bently Nevada Transmittal, reproduction, dissemination and/or editing of this document as well as utilization of its contents and communication thereof to others without express authorization are prohibited. Offenders will be held liable for payment of damages. All rights created by patent grant or registration of a utility model or design patent are reserved. Department responsible Technical reference © Innomotics 2024 Branding disclaimer applies Document type Document status Option description Document title Document number Shaft vibration monitoring for sleeve bearings Innomotics HV C/M/HP, HS Order option A02 Edition date (YYYY-MM-DD)

Open the catalog to page 1

2 Technical data Type Type Probe Type Signal converter Bently Nevada Type of protection Signal converter IECEx/ATEX Class I Zone 0 / Class I Division 1, Groups A, B, C, D (1109248) Class I Zone 2 / Class I Division 2, Groups A, B, C, D (1109248) Type of protection Probe IECEx/ATEX Class I Zone 0 / Class I Division 1, Groups A, B, C, D (1109248) Class I Zone 2 / Class I Division 2, Groups A, B, C, D (1109248) Additional certificates Scope of delivery for each bearing 2 × Proxpac 3300 XL, fastened and wired to the auxiliary terminal box Calibration certificate The information provided in the...

Open the catalog to page 2All INNOMOTICS catalogs and technical brochures

-

Y87

1 Pages

-

SINAMICS CU320 control unit

2 Pages

-

K86

2 Pages

-

SINAMICS PERFECT HARMONY GH180

90 Pages

-

D02

2 Pages

-

D03

2 Pages

-

D04

2 Pages

-

D021

2 Pages

-

E9x

4 Pages

-

K51

1 Pages

-

P61

2 Pages

-

Innomotics Training Services

4 Pages

-

NXGPro+

2 Pages

-

SISynch

5 Pages

-

High Voltage Motors HV C

572 Pages

-

Medium Voltage Drives GM150 SM150

202 Pages

-

SINAMICS S200

156 Pages

-

SINAMICS S210

476 Pages

-

SIMOTICS Motors for Cranes

118 Pages

-

SINAMICS G220

112 Pages

-

SINAMICS Low Voltage Converters

34 Pages

-

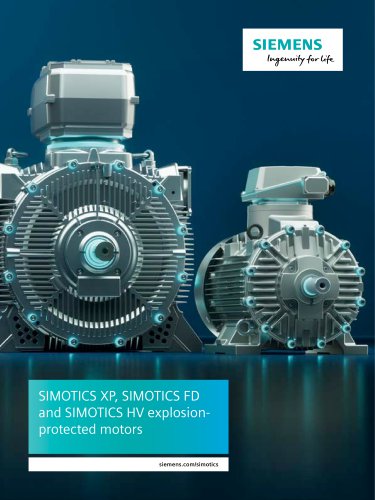

The SIMOTICS HV family

7 Pages

-

SIMOTICS low-voltage motors

36 Pages

-

SC600 and SIDRIVE IQ

8 Pages

-

DC motors

44 Pages