Catalog excerpts

SGT screw jack Product description SGT 5 to SGT 1000 screw jack Both trapezoidal and ball screw versions ALBERT-SGT-screw jacks are electromechanical transmission components suitable for a wide spectrum of industrial machinery. A range of 11 sizes, coupled with a modular approach to nut and installation arrangements, satisfy customer design requirements. The range has a logical progression of load capability between 5 and 1000 kN. Higher loads are possible and spindles up to 10m long can be provided. Normal stroke speeds up to 0.05m/s: For higher speeds please enquire. Logically designed combinations of standard components, with good interchangeability, make simple installation possible whilst permitting operation in any chosen position and attitude with minimum space requirement. ALBERT-SGT-screw jacks can be provided with electrical, hydraulic, pneumatic and manual inputs. Precise relative motion is provided for screw jacks used in combination but with unequal loads. Rest positions are maintained by the self locking trapezoidal spindle or by the use of a brake motor. Environmental temperatures between -50°C and +200°C are possible. High operational safety is ensured by the choice of compatible materials and simple installation and maintenance. For more extreme mechanical or chemical conditions, ALBERTSGT-screw jacks are manufactured with suitable special materials. The enclosed construction, including comprehensive spindle protection, allows utilisation in hostile conditions. Standard options include Safety Nuts, Ball Screw Spindles (for high utilisation or lifting speeds), spindle rotation prevention and backlash compensation. Special spindle diameters and leads can also be supplied. Application examples: Production Equipment, Assembly and Repair, Storage and Mechanical Handling, Paper, Food, Rolling Mills and Foundries, Mining and Metal manufacturers, Building, Water and Ship Building (exposed deck equipment), Research and Development, New Technologies, Theatre and Stage Engineering. The wide range of available accessories ensures the closest possible match to customer requirements. If you have questions or problems our Technical and Sales personnel will be very pleased to hear from you. We are always happy to offer our experience and provide assistance with the design of drives and equipment.

Open the catalog to page 1

SGT screw jack Contents list SGT screw jacks - basic design and running nut design Page Versions basic design GO, GU running nut design LO, LU Dimensions SGT 5 to SGT 1000 GO, GU dimensions for SGT 5, SGT 20 and SGT 500 dimensions for SGT 30 to SGT 350, SGT 750 and SGT 1000 standard spindle ends for versions GO, GU initial selection table Dimensions SGT 5 to SGT 1000 LO, LU dimensions for SGT 5, SGT 20 and SGT 500 dimensions for SGT 30 to SGT 350, SGT 750 and SGT 1000 standard spindle ends for versions LO, LU initial selection table Trapezoidal spindle standard dimensions Input power and...

Open the catalog to page 2

SGT screw jack Contents list SGT screw jacks - basic design and running nut design Calculations Maximum radial load Fr max. [N], duty ED [%/h], input torque Min. [Nm] at the worm shaft, selection of the motor, torque MSp. [Nm] in the lifting spindle total input torque Mtot. [Nm], spindle efficiency spindle [-], surface stress in thread p [N/mm²], life Lh [h] ball screw spindle/ ball bearing critical spindle speed ncrit. [1/min] (only running nut design) Permissible side loading FS [kN] on the spindle due to compressive loads critical buckling loads Fcrit. [kN] on the spindle Gear housing...

Open the catalog to page 3

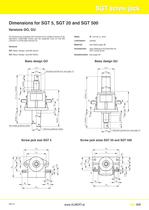

SGT screw jack Versions Basic design GO, GU G configuration (basic design) has two versions: GO (basic design, spindle above) and GU (basic design, spindle below). In both cases the spindle moves to transmit the linear lifting motion. The spindle is axially guided through the screw jack gear housing. Any tendency of the spindle to rotate must be resisted. Basic design Basic design GO Trapezoidal spindle Ball screw spindle

Open the catalog to page 4

SGT screw jack Versions Running nut design LO, LU L configuration (running nut) has two versions: LO (running nut, spindle above) and LU (running nut, spindle below). The axial movement of the nut transmits the linear lifting motion due to spindle rotation. In this configuration the spindle is axially fixed in the gear housing. Running nut design Running nut design LO Trapezoidal spindle Ball screw spindle

Open the catalog to page 5

SGT screw jack Dimensions for SGT 5, SGT 20 and SGT 500 Versions GO, GU All versions are supplied with double worm shafts (version 0) as standard. Optionally these can be supplied only on the left (version 1) or the right (version 2). GU: Basic design, spindle below grease see table page 48 GO: Basic design, spindle above see catalogue accessories for SGT screw jacks Standard spindle end, see page 10 with single guidance collar with two guidance collars Ø Standard spindle end, see page 10 Screw jack sizes SGT 20 and SGT 500 Screw jack size SGT 5

Open the catalog to page 6

Dimensions [mm] Order code SGT 5 SGT 20 SGT 500 Dimensions [mm] Order code Only valid for versions in standard materials. General tolerances to DIN ISO 2768 - medium, apply to machined surfaces. For all other dimensions casting tolerances apply.

Open the catalog to page 7

SGT screw jack Dimensions for SGT 30 to SGT 350, SGT 750 and SGT 1000 Versions GO, GU All versions are supplied with double worm shafts (version 0) as standard. Optionally these can be supplied only on the left (version 1) or the right (version 2). Versions GO: Basic design, spindle above GU: Basic design, spindle below Standard spindle end, see page 10 with two guidance collars Ø Screw jack sizes SGT 30 to SGT 350 with single guidance collar Standard spindle end, see page 10 Screw jack sizes SGT 750 and SGT 1000 H3 H4

Open the catalog to page 8

Dimensions [mm] Order code SGT 30 SGT 50 SGT 150 SGT 200 SGT 300 SGT 350 SGT 750 SGT 1000 Dimensions [mm] Order code Only valid for versions in standard materials. General tolerances to DIN ISO 2768 - medium, apply to machined surfaces. For all other dimensions casting tolerances apply.

Open the catalog to page 9All INKOMA catalogs and technical brochures

-

KL spiral bevel gear units

6 Pages

-

DSH screw jack

16 Pages

-

HSG screw jack (cubic design)

34 Pages

-

INKOMA - LA Linear actuators

2 Pages

-

ALBERT manufactured spindles

2 Pages

-

INKOMA - Inkoturn couplings

2 Pages

-

INKOMA - Elaflex couplings

2 Pages

-

INKOMA - Inkocross couplings

2 Pages

-

INKOMA - KSO couplings

2 Pages

-

INKOMA - Inkoflex couplings

2 Pages

-

INKOMA - Lineflex couplings

2 Pages

-

INKOMA - PK couplings

2 Pages

-

INKOMA - products

1 Pages