Catalog excerpts

Electric Chain Hoist ELK Series 1/8 to 2 ton Product Maintenance Information Save These Instructions Ingersoll Rand, Edition 4 May 2018 CCN 47584689001

Open the catalog to page 1

Only allow Ingersoll Rand trained technicians to perform maintenance on this product. For additional information contact Ingersoll Rand factory or nearest Distributor. For additional supporting documentation referto Table 1, p.2. Manuals can be downloaded from ingersollrandproducts.com The use of other than genuine Ingersoll Rand replacement parts may result in safety hazards, decreased performance and increased maintenance and will invalidate all warranties. Original instructions arein English. Other languages area translation of the original instructions. Refer all communications to the...

Open the catalog to page 2

According to ASME B30.16, frequency of periodic inspection depends on the severity of usage: Disassembly may be required for Heavy or Severe usage. Keep accumulative written records of periodic inspections to provide a basis for continuing evaluation. Inspect all the items shown in "Frequent Inspection" section of Product Information Manual (47584686001). Also, inspect the following: 1. Fasteners: Check all rivets, split pins, capscrews and nuts. Replace if missing or tighten if loose. 2. All components: Inspect for wear, damage, distortion, deformation and cleanliness. If external evidence...

Open the catalog to page 3

Inspection Figure 1. Chain Records and Reports Inspection records, listing all points requiring periodic inspection should be maintained for all load bearing equipment. Written reports, based on severity of service, should be made on the condition of critical parts as a method of documenting periodic inspections. These reports should be dated, signed by the person who performed the inspection, and kept on file where they are readily available for review. Load Chain Reports Records should be maintained documenting the condition of load chain removed from service as part of a longrange load...

Open the catalog to page 4

Table 2. Load Chain

Open the catalog to page 5

Ingersoll Rand ELK Electric Chain Hoist ELK Series

Open the catalog to page 6

Inspection Report (a) Maximum test load should neverexceed 125% of rated capacity. This form may be photocopied and used as an inspection record.

Open the catalog to page 7

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections performed by personnel instructed in safety, operation and maintenance ofthis equipment. The chart below provides a briefguide to common hoist symptoms, probable causes and remedies.

Open the catalog to page 8

Never perform maintenance on the hoist while it is supporting a load. Before performing maintenance, tag controls: Only allow personnel trained in service and repair of this hoist to perform maintenance. After performing any maintenance on the hoist, test hoist before returning hoist to service. Turn off and lockout/tag out electrical disconnect switch before performing any maintenance. The lower sheave block or hook assembly must be lying on the floor or a maintenance platform before beginning service. WARNING - DO NOT OPERATE - EQUIPMENT BEING REPAIRED. General Maintenance Instructions It...

Open the catalog to page 10

Do not heat a part with a flame to free it for removal, unless the part being heated is already worn or damaged beyond repair and no additional damage will occur to other parts. NOTICE In general, the hoist is designed to permit easy disassembly and assembly. The use of heat or excessive force should not be required. 5. Keep the work area clean to prevent dirt and other foreign matter from getting into bearings and other moving parts. All seals and ‘O’ Rings should be discarded once they have been removed. New seals and ‘O’ Rings should be used when assembling the hoist. When grasping a...

Open the catalog to page 11

Maintenance Cover Removal Electrical side is indicated by Symbol. Brake System (DC Brake) The spring loaded brake is an solenoid operated single disk brake with two friction surfaces. The braking force is applied by springs. The braking torque is generated when no current is applied. The ventilation is solenoid. The brake operates with DC current. In the power free mode, the brake must be able to hold the nominal load without any problems. Figure 2. Brake CAUTION The brake coil voltage must be the same as the operating voltage. NOTICE Replace brake discs if they are distorted or severely...

Open the catalog to page 12

Brake Test 1. Use a test load that is 100% of hoist capacity. 2. With cover off, hoist load, in low speed mode, approximately 1 ft. (0.3 m). 3. Listen to brakewhile hoisting. 4. When hoisting stops, brake should hold load. Table 4. BrakeAir Gap (DC Brake) Load Chain Before conducting maintenance on the hoist, lower and remove suspended load. Disconnect electrical supply and remove hoist from overhead suspension. • The chain is to be replaced when the measurements exceed those defined in Table 2 'Load Chain'. The chain wheel and chain guide are to be checked for wear at the same time, and,...

Open the catalog to page 13

Screw connections at the limit stop and shims at lower sheaves are to be checked and, where necessary, tightened to the right torque. For torque values see Table 5, p. 14. Table5. TorqueValues The gear has continuous lubrication The Gear Compartment is filled with grease at the factory. Replacement of thegrease for the life of the hoist is not required. Slip Clutch The slip clutch is set to work at 125% and prevents overloading of the chain hoist. This is in accordance with DIN EN 14492-2. Resulting force arising from adjusting the slip clutch must be absorbed by the suspension parts. The...

Open the catalog to page 14

the new possible theoretical utilization the max. period until the next general overhaul Such data is to be documented in the inspection report. Table 6. General Overhaul Motor Shaft Antifriction bearing Chain wheel, chain guide Travelling gear, running wheel Contactor, limit switch Load hook

Open the catalog to page 15

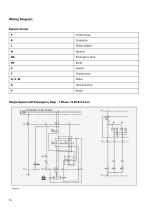

Wiring Diagram Electric Circuit F Control fuse Power supply Emergency stop Terminal strip Single Speed with Emergency Stop - 1 Phase / 0.25 & 0.5 ton

Open the catalog to page 16

Wiring Diagram Dual Speed with Emergency Stop - 3 Phase / 0.25 & 0.5 ton Dual Speed with Emergency Stop - 3 Phase / 1 ton

Open the catalog to page 17All INGERSOLL RAND catalogs and technical brochures

-

Ergonomic Handling Systems

52 Pages

-

Industrial Lifting Equipment

51 Pages

-

BOP HANDLING SYSTEM

13 Pages

-

Liftstar and Pullstar Winches

12 Pages

-

Liftstar Heavy Air winches

4 Pages

-

Pullstar Heavy Air winches

4 Pages

-

Liftstar Portable Air

4 Pages

-

SideKick Flyer

2 Pages

-

Fulcrum Winches

12 Pages

-

Manual Hoists

20 Pages

-

ELK Series Electric Hoist

4 Pages

-

Winch & Hoist

8 Pages

-

VORTEX VT22 TURBINE GRINDER

3 Pages

-

W5001 SERIES

6 Pages

-

W7150

6 Pages

-

X-SERIES SYSTEM AUTOMATION

8 Pages

-

Infinity FA10i Air Winches

4 Pages

-

Arm Systems

8 Pages

-

Winches & High Capacity Hoists

92 Pages

-

Winch & Hoist Catalog 2012

68 Pages

-

TIR6600 Series

3 Pages

-

RT Series

1 Pages

-

PT and GT Series

2 Pages

-

Rail Systems

6 Pages

-

Jib crane

7 Pages

-

VL2 " Premium" Series

1 Pages

-

SLB "Silver" Series

1 Pages

-

L5H "Premium" Series

1 Pages

-

P Series Ratchet Puller

1 Pages

-

C Series Ratchet Puller

1 Pages

-

LIFTCHAIN® Hydraulic Hoist

8 Pages

-

LIFTCHAIN® Chain Hoist Series

10 Pages

-

MLK Chain Hoist Series

9 Pages

-

Handling Device Catalog

6 Pages

-

Balancers

12 Pages

-

Industrial Lifting Equipment

20 Pages

-

CLK Series Air Chain Hoist

6 Pages

-

Spring Balancers

2 Pages