Catalog excerpts

25 to 250 Metric Tons Capacity

Open the catalog to page 1

THE OIL & GAS INDUSTRY For over 50 years, Ingersoll Rand has ® designed, manufactured, and serviced hundreds of Blowout Preventer (BOP) Handling Systems for all the major drilling contractors and oil companies MODULAR CONCEPT Our tough systems feature a new modular “platform” design that can accomodate either gear or piston air motors, as well as hydraulic versions. Find the right headroom size, choose your bottom attachment and control type, Ingersoll Rand engineers designed this concept to make things simple for you. This modular design combined with our commitment to safety and quality...

Open the catalog to page 2

STANDARD FEATURES STANDARD FEATURES ALL MODELS • All steel/cast iron construction • 5:1 design factor on load bearing parts • Group Mechanism: FEM 1Bm (ISO M3) • -20°C design temperature • Automatic Fail Safe multi disc brake on hoist and trolley (Self-locking worm drive gear box on BHS trolley) • Fully enclosed planetary gear box • Articuled trolley allowing side pulling operations of + / - 20°(not available on LBS and ULBS series) SPECIFIC TO AIR OPERATED SYSTEMS • 2 motors “PHS” variable speed pendant control (one per hoist) • 9 meter of control drop • Pneumatic limit switches for...

Open the catalog to page 3

OPTIONAL FEATURES STANDARD FEATURES CORROSION PROTECTION • Corrosion resistant load chain • Corrosion resistant Marine paint • Corrosion resistant bolting (Stainless steel up to M10, hot dip galvanized > M10) TESTING • Test at nominal load of speeds and controls • Dynamic test at 110% of Safe Working Load • Brake Static test at 125% of SWL • Adjustment of overload protection as per EN14492-2 (CE certified models only) DOCUMENTATION • Test Reports, Technical Datasheets • Installation and safety manual in multiple languages • Spare parts manual (English only) • Instruction manual (English...

Open the catalog to page 4

BS SERIES GEAR AIR MOTOR BHS SERIES PISTON AIR MOTOR Gear motors have only two moving parts, which reduces the complexity of motor maintenance. The high torque feature provides outstanding control at low speed. Gear motors will better tolerate the wet and dirty air supply than any other technologies. Built from the famous Liftchain series frame, the new BHS series features a performant piston air motor of 9.4hp. Very versatile, our new platform concept use the widespread Herculink™ piston motor to enrich the largest choice of BOP handling hoists in the market. • Radial Piston type air motor...

Open the catalog to page 5

LBS SERIES GEAR AIR MOTOR ULBS SERIES GEAR AIR MOTOR Ultra-Low Headroom Models When huge BOP stack size becomes a problem for most of standard cranes, Ingersoll Rand® Low Headroom LBS Series, can sneak in a very small space. Low profile BOP handling systems can be optioned with rack and pinion trolley drives for positive traction. A choice of various attachments offers extra space saving to tailor the product to your needs. Ingersoll Rand® Ultra Low Profile BOP Handling Systems feature the same reliable operation and durable construction while providing even more clearance for BOP stack...

Open the catalog to page 6

Ingersoll Rand® has developped a large range of options and pneumatic accessories to provide you a key on hand solution. CONTROLS When the BOP system has to be installed on a bi-directional bridge crane, the PHS6 pendant allows the full control of the 3 movments. The progressive control levers provides an exceptionnal variable speed control of the load. Various versions are available to meet CE and ATEX requirements. The Accu-trol™ pendant is an alternative to the standard PHS pendant, offering a vertical arrangement of the control buttons in a fully enclosed impact resistant frame....

Open the catalog to page 7

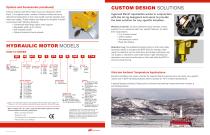

BS SERIES HYDRAULIC MOTOR LBS SERIES HYDRAULIC MOTOR The LIFTCHAIN® Hydraulic Chain Hoist series is an innovative alternative to our air driven chain hoists. With a very low noise level, Ingersoll Rand® Hydraulic BOP Systems provides extremely sensitive variable speed control of lifting and travelling motions combined with a very low noise level. Ingersoll Rand® Low Profile BOP Handling Systems feature the same reliable operation and durable construction while providing even more clearance for BOP stack operation. Spark resistant, ATEX Zone 1 packages are available. • Piston or orbital...

Open the catalog to page 8

ULBS SERIES HYDRAULIC MOTOR HYDRAULIC MOTOR MODELS Ultra-Low Headroom Models The BS Series BOP Handling Systems can be designed in ultra-low headroom version for applications requiring a very limited working height — range of capacities from 100 to 250T. The minimum headroom of these products is only slightly greater than the size of the bottom hook assembly. Our Hydraulic BOP Handling Systems can benefit of many options and accessories to suit your application. Ingersoll Rand® Hydraulic BOP Systems can be delivered with a full flow control, meaning that up-down and forward reverse commands...

Open the catalog to page 9

CUSTOM DESIGN SOLUTIONS Options and Accessories (continued) Festoon trolleys with either steel or bronze wheels (for ATEX Zone 1) to support hoses; number of festoon trolley has to be determined depending on the travel length and the possible loop maximum height. These trolleys are dsigned for long-life in harsh environment with following features: • Galvanized steel large radius hose support • Adjustable width up to 310mm • Anti-kickback wheel • Optional massive bronze wheels Ingersoll Rand® specialists works in conjunction with the oil rig designers and users to provide the best solution...

Open the catalog to page 10

ENCOMPASS RECERTIFICATION PROGRAM TROLLEY SELECTION Blowout Preventer (BOP) Handling Systems are critical to your operation. Encompass is designed to prolong the life of this equipment and ensure it runs safely when you need it by streamlining start-up, inspection, maintenance and overhaul processes. In addition to extending your warranty, you’ll benefit from reduced costs related to unplanned repairs and improved productivity. Using the right trolley size is crucial for your installation. Ingersoll Rand® has created 2 trolley sizes in order to match any configuration, even with very large...

Open the catalog to page 11All INGERSOLL RAND catalogs and technical brochures

-

Ergonomic Handling Systems

52 Pages

-

Industrial Lifting Equipment

51 Pages

-

Liftstar and Pullstar Winches

12 Pages

-

Liftstar Heavy Air winches

4 Pages

-

Pullstar Heavy Air winches

4 Pages

-

Liftstar Portable Air

4 Pages

-

SideKick Flyer

2 Pages

-

Fulcrum Winches

12 Pages

-

Manual Hoists

20 Pages

-

ELK Series

20 Pages

-

ELK Series Electric Hoist

4 Pages

-

Winch & Hoist

8 Pages

-

VORTEX VT22 TURBINE GRINDER

3 Pages

-

W5001 SERIES

6 Pages

-

W7150

6 Pages

-

X-SERIES SYSTEM AUTOMATION

8 Pages

-

Infinity FA10i Air Winches

4 Pages

-

Arm Systems

8 Pages

-

Winches & High Capacity Hoists

92 Pages

-

Winch & Hoist Catalog 2012

68 Pages

-

TIR6600 Series

3 Pages

-

RT Series

1 Pages

-

PT and GT Series

2 Pages

-

Rail Systems

6 Pages

-

Jib crane

7 Pages

-

VL2 " Premium" Series

1 Pages

-

SLB "Silver" Series

1 Pages

-

L5H "Premium" Series

1 Pages

-

P Series Ratchet Puller

1 Pages

-

C Series Ratchet Puller

1 Pages

-

LIFTCHAIN® Hydraulic Hoist

8 Pages

-

LIFTCHAIN® Chain Hoist Series

10 Pages

-

MLK Chain Hoist Series

9 Pages

-

Handling Device Catalog

6 Pages

-

Balancers

12 Pages

-

Industrial Lifting Equipment

20 Pages

-

CLK Series Air Chain Hoist

6 Pages

-

Spring Balancers

2 Pages