Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

VSM-95 Rev 2 4/18/07 10:57 AM Page 1 VSM-95 One, Two or Four-Spindle, Vertical Scanning Precision Induction Hardening Machine Features/Benefits: • Scan hardens cylindrical parts up to (80 in./2030 mm) long with weights up to (300 lbs./135 kg on single spindle) (400 lbs./180 kg max. total) • Single or dual position tooling for optimum machine usage • Easily adapts to most heat stations • User friendly controls simplify set-up, changeover and trouble-shooting, includes PLC with industrial computer operator interface • Pre-plumbed integral quench system for a controlled, clean quench • Multiple operating modes are easily selected for maximum application flexibility • High speed index capability for exceptional productivity Rugged Production Hardening System Self-Contained Quench System A completely pre-plumbed, self-contained quench system features a plate and frame water-to-water heat exchanger for low plant water demand and easy cleaning. A bronze fitted integral pump motor combination eliminates alignment problems. The quench tank has epoxy coated surfaces for long life. A four outlet quench manifold allows the user to balance each line separately for uniform quench impingement. A suction strainer and in-line basket strainer with dual filters assures a clean quench. Integrating our experience and technology has paved the way for developing this precision vertical hardening system (VSM-95). The outstanding rigidity of our design results in repeatability of better than ± .002 in. Heavy-duty hardened and chrome plated shafting with bearing seals, wipers and scrapers means long life and low maintenance. In addition to scanning, our flexible system performs a variety of static applications such as single shot hardening, tempering, annealing and gear hardening. The standard low maintenance, large servo allows a high speed index without sacrificing slow speed accuracy for increased productivity. The standard available model includes many special mechanical features with a wide variety of options to expand the application range including a second work station. Programmable For Maximum Flexibility The standard VSM-95 has a programmable logic controller (PLC) based closed-loop servo control. Individual 36 step part process program controls position, power level, dwell time, scan speed, rotation speed and quench on/off. It also features a real time display of process parameters. The control cycles automatically through intermittent heating and quenching times at selected scanning speeds. It is easily reprogrammed for static and lift-and-rotate applications. To further simplify set-up, the upper tooling carriage can be adjusted up/down without tools. Options are available for even more versatility. See our option sheet, Bulletin HT-45 OP, for details. For more information, call 800/624-6297 or visit www.inductoheat.com

Open the catalog to page 1

An Induclolherm Gnjif) Company Precision Induction Hardening Machine Inductoheat, Inc. 32251 N. Avis Dr., Madison Heights, Ml 48071 hardening with 25kHz power Uppers centers adjustable without tools operator touch screen ©2007 Inductoheat, Inc. All rights reserved. 500 04/07 LITHO IN U.S.A. HT-45 Rev. 2 Leading Manufacturers of Melting, Thermal Processing & Production Systems for the Metals & Materials Industry Worldwide

Open the catalog to page 2All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

STATISCAN II and IV

2 Pages

-

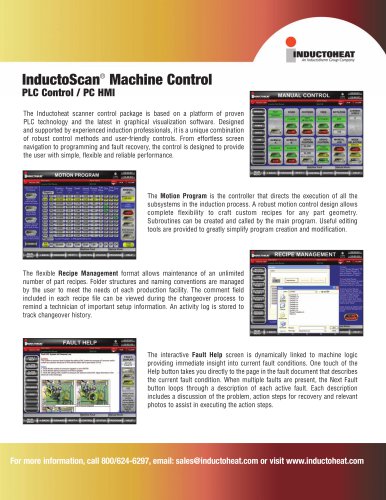

InductoScan PC HMI-PLC

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages