Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

Unitized Vertical-Scanning System with Two or Four Spindles Features/Benefits • Two spindles to process two parts at a time • Also available as a four spindle in a dual tower/dual power supply configuration • Scans part lengths of 30 in., with maximum scan heated length of up to 24 in. on standard model • Self-contained, compact design for minimal floor space and ideal for workcell • Different power ratings and frequency ranges available for application matched precision hardening • User-friendly controls simplify set-up, changeover and diagnostics • Built to machine tool standards for reliable performance • Simple utility connection for fast installation and relocation Two-Spindle Induction Heating System Low to Mid Volume Production Hardening System ® The STATISCAN can be configured as a single, dual or four spindle, vertical scanning system for hardening or tempering a wide variety of parts. Standard power ratings are available from 50-300 kW at 10-200 kHz depending on the application. Compact, Unitized Machine Design ® The STATISCAN system features a built-in transistorized solid state power supply with heat station, programmable scanner controls, quench and water recirculating system. This unitized construction reduces floor space 50-80% compared to conventional systems. Special Features to Speed Changeover Rugged Design For Long-Life Performance A user-friendly HMI on the STATISCAN® provides quick set-up, changeover and diagnostics capability. To further simplify set-up, the upper tooling carriage can be adjusted up/down without tools. A selection of standard Insta-Change inductor mountings are also available to minimize changeover time. The STATISCAN system is field proven with over 200 systems worldwide. Scanning towers are constructed with 1.5 in. diameter hardened chrome plated shafts, bronze bearings, stainless steel guide bars and 2 in. thick machined anodized aluminum plates. A DC rotation motor and AC servo motor scan for repeatability and positioning accuracy. For more information, call 800/624-6297 or visit www.inductoheat.com

Open the catalog to page 1

Inductoheat, Inc. 32251 N. Avis Dr., Madison Heights, MI 48071 TEL: (248) 585-9393 FAX: (248) 589-1062 Unitized Vertical-Scanning System with Two or Four Spindles SPECIFICATIONS FOR TWO SPINDLE SYSTEM: Power & Frequency Ratings Workpiece Capacity Length: 30 in. (760 mm) Weight: 22 lbs. (10 kg/spindle) Scanning Distance Workpiece Loading Manual load/unload Scanning Speed Spindle Rotation Quench Systems Water-to-water heat exchanger with centrifugal pump, digital temperature controller, quench heater and front-mounted pressure gauge and valve. Closed-loop, nonferrous reservoir, heat...

Open the catalog to page 2All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

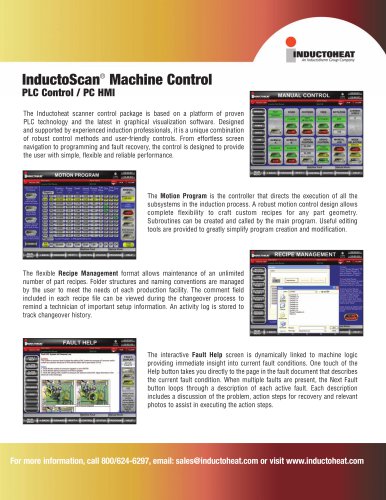

InductoScan PC HMI-PLC

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages

-

VSM-95

2 Pages