Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

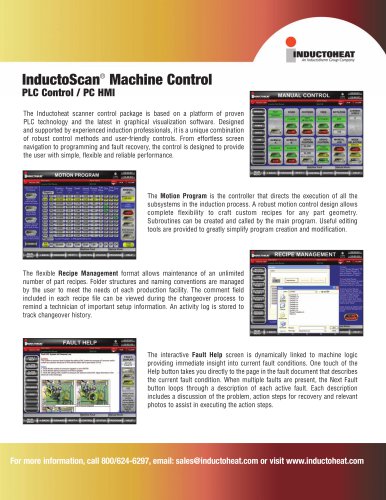

InductoScan® Machine Control The Inductoheat scanner control package is based on a platform of proven PLC technology and the latest in graphical visualization software. Designed and supported by experienced induction professionals, it is a unique combination of robust control methods and user-friendly controls. From effortless screen navigation to programming and fault recovery, the control is designed to provide the user with simple, flexible and reliable performance. i |f <BAC* ||f QRVMAfiDfl NEXT' ||C0NTTKM.| STATUS Hpnl?QHAMH HilP i V ', H <MU( MF™WAflQH Nj*r L ||COWTItQL0 STATUS tyPROGIUMty HELP The Motion Program is the controller that directs the execution of all the subsystems in the induction process. A robust motion control design allows complete flexibility to craft custom recipes for any part geometry. Subroutines can be created and called by the main program. Useful editing tools are provided to greatly simplify program creation and modification. The flexible Recipe Management format allows maintenance of an unlimited number of part recipes. Folder structures and naming conventions are managed by the user to meet the needs of each production facility. The comment field included in each recipe file can be viewed during the changeover process to remind a technician of important setup information. An activity log is stored to track changeover history. The interactive Fault Help screen is dynamically linked to machine logic providing immediate insight into current fault conditions. One touch of the Help button takes you directly to the page in the fault document that describes the current fault condition. When multiple faults are present, the Next Fault button loops through a description of each active fault. Each description includes a discussion of the problem, action steps for recovery and relevant photos to assist in executing the action steps. M --BACK HtOHlNAHC/ti NEXT * ipCLWIHULfl STATUS tyPROGNAMty HELP e information, call 800/624-6297, email: sales@inductoheat.com or visit www.inductoheat.com

Open the catalog to page 1

An Inductotherm Croup Company InductoScan® Machine Control Inductoheat, Inc. 32251 N. Avis Dr., Madison Heights, Ml 48071 Trend screens provide a graphical view of machine performance relative to upper and lower control limits over a time period. They also show when a control limit has been changed. A trend screen is provided for each parameter being monitored, and the most recent 999 samples for each parameter are stored. The graph is interactive and allows the user to define the number of cycles per sample and the number of samples to display. MACHINE MANUAL A complete interactive library...

Open the catalog to page 2All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

STATISCAN II and IV

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages

-

VSM-95

2 Pages