Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

InductoForge™ Billet Heater Tractor Infeed Drive Options The heavy-duty tractor chain drive in-feed system pushes billets through the induction coil line at an accurate controlled speed. This drive system combines the advantages of a pinch roll drive-easy automatic adjustment to billet size-with the extended billet gripping surface area of the tractor drive. Features/Benefits: • The heavy-duty reduction gear box drives both the top and bottom chain that is controlled by an extremely accurate AC variable frequency motor drive. • A pneumatic cylinder lowers the upper chain drive to “pinch” the billets. • A key safety feature is a lost-motion detector that will shut down the system’s power supply if the billets stop for any reason. • The extended upper and lower chain assembly allows for greater billet surface contact which greatly reduces slippage. • The drive includes an in-feed conveyor that operates 1.5 to 2X faster than the drive chains to avoid billet gaps. Heavy-duty twin chain tractor infeed drive • Grips either round or RCS billets Heavy-Duty, Multi-Strand Chain Infeed Conveyor Flexible Design For Long Life Performance The Tractor Chain Drive's in-feed conveyor has adjustable side plates for a wide range of billet diameters. This keeps billets centered in the conveyor for proper feeding to the chain drive assembly. The conveyor is driven by the main gear box and uses the same drive motor. The tractor drive is equipped with a pneumatically positioned upper chain assembly that automatically adjusts for different billet diameters. This provides for quick change-over resulting in improved productivity. The upper drive assembly is spring loaded to allow for small diameter variations from part to part without affecting the feed rate. For more information, call 800/624-6297 or visit www.inductoheat.com

Open the catalog to page 1

An inductotherm Group Company Billet Heater Tractor Infeed Drive Options Inductoheat, Inc. 32251 N. Avis Dr., Madison Heights, Ml 48071 Tractor Drive/Billet push-out device Close-up of heavy-duty twin chain tractor infeed drive Infeed conveyor InductoForge™ modular billet heating system Lost motion Conveyor drive •Sprocket sizes •Catch-up ratio Pusher drive Chain tensioner Pusher drive ©2007 Inductoheat, Inc. All Rights Reserved. 200 02/07 BULLETIN F-71 Leading Manufacturers of Melting, Thermal Processing & Production Systems for the Metals & Materials Industry Worldwide

Open the catalog to page 2All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

STATISCAN II and IV

2 Pages

-

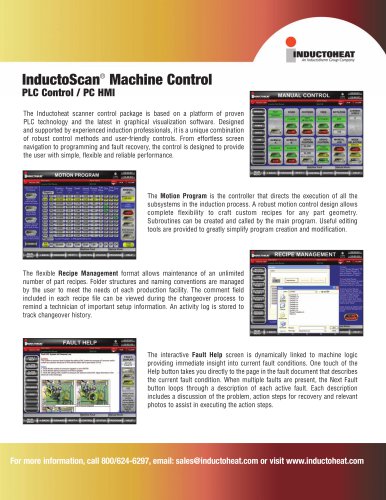

InductoScan PC HMI-PLC

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages

-

VSM-95

2 Pages