Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

Solutions Dedicated to the World of Induction Heating Induction heating, heat treating & forge heating

Open the catalog to page 1

Dedicated to meeting your production needs... With effective induction heating solutions Inductoheat Inc. has been headquartered in Madison Heights, MI for over 50 years, here we provide customers with patented technologies, high quality induction equipment and dedicated customer support. We work on specialized programs for some of the most respected companies in the World, encompassing an array of industries: Our team of scientists, engineers and maintenance experts blend a variety of techniques to establish the perfect heating solution specifically suited for your processing needs. Our...

Open the catalog to page 3

The World Leader in Solid-State Induction Heating Power Supplies Induction Heating Power Supplies Customer focused and application driven, our engineers can draw from well proven SCR, IGBT and MOSFET technologies for each and every customer application, satisfying diverse requirements for power and frequency the world over. Thermal Processing Solutions Tailored To Your Application: 0.05kHz - 800kHz / 2.5kW - 4MW MODEL SEMI. LOAD FREQ. (kHz) POWER (kW) OUTPUT (VOLTS) EZ-VIP SCR Series 0.05 – 6 150 – 4000 600 - 3000 With a clear desire to remain world leader for induction power supplies,...

Open the catalog to page 4

Induction Heat Treating Systems Designed to fit the flexible manufacturing requirements of today’s commercial heat treaters. M any metals require heating and/or heat treating to achieve their optimum physical properties. Our focus is to provide a family of high quality induction heating systems that meet your process and application requirements. No matter the size or geometry of your part, we supply standardized and custom induction systems that produce superior long lasting parts time and time again. InductoScan® modular induction heating system 25 - 300kW @ 3 - 200 kHz Perfect for almost...

Open the catalog to page 5

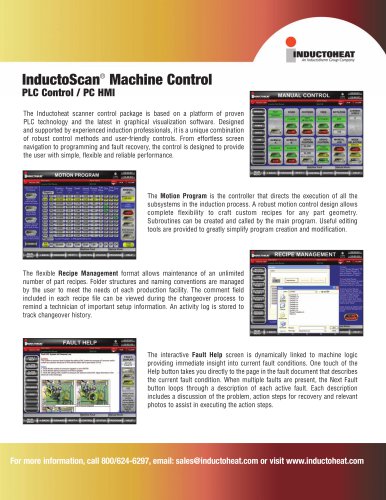

Advanced System Controls PC-HMI Interface Intuitive, user-friendly, touch-screen controls. MANUAL CONTROL Premiere System Controls The Inductoheat scanner control package is based on a platform of proven PLC technology and the latest in graphical visualization software. Designed and supported by experienced induction professionals, it is a unique combination of robust control methods and user-friendly controls. From effortless screen navigation to programming and fault recovery, the control is designed to provide the user with simple, flexible and reliable performance. Features & Benefits:...

Open the catalog to page 6

IROSS™ Pipe-End Heating Systems For OCTG Flexible, 50/60 Hz Heating Solutions For Tube & Pipe. Induction Tube & Pipe Heating IROSS™ Pipe-End Heating Units are designed specifically for heating a variety of tubular products. These systems utilize patented fluxmanager technology that yields superior temperature uniformity compared to conventional medium frequency designs. Inductoheat and sister company Thermatool Corp., offer a variety of induction heating systems for the pipe and tube industry. Thermatool’s focus is on the tube and pipe producers, while Inductoheat offers induction equipment...

Open the catalog to page 7

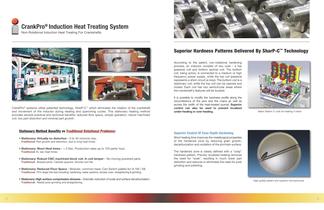

CrankPro® Induction Heat Treating System Non-Rotational Induction Heat Treating For Crankshafts. Superior Hardness Patterns Delivered By SharP-C™ Technology According to the patent, non-rotational hardening process, an inductor consists of two coils - a top (passive) coil and bottom (active) coil. The bottom coil, being active, is connected to a medium or high frequency power supply, while the top coil (passive) represents a short circuit (a loop). The bottom coil is a stationary coil, while the top coil can be opened and closed. Each coil has two semicircular areas where the crankshaft’s...

Open the catalog to page 8

InductoForge® Modular Induction Billet Heaters Designed to fit the flexible manufacturing requirements of today’s forge shop. The powerful combination of advanced engineering, product innovation and over 50 years experience in induction heating has helped Inductoheat become a world leader in them production of billet and bar heating equipment for the forging industry. The InductoForge® Modular Billet Heating System offers flexibility and efficiency with its individually controlled (500Hz - 6000Hz) power modules. The flexible modular design results in a much finer and more accurate control...

Open the catalog to page 9

Newelco Brand Bar Line Heaters Shaping the future of induction bar heating technologies. Over 50 years of experience in induction heating has made Inductoheat the world leader in the production of billet and bar heating equipment for the forging industry. The Newelco product brand produces a wide range of bar heaters to feed automatic forging machines, hot shear lines and rolling mills. When customers requirements’ go beyond standard equipment, we will design and manufacture a system to meet your specific needs. Increased Productivity Newelco bar heater line productivity can be further...

Open the catalog to page 10

Induction Gear Hardening Systems Successfully induction harden gears for over 40 years Just like gears, induction heating is all about Precision. Inductoheat’s accurately controlled, induction gear hardening systems provide specific metallurgical patterns, minimum shape distortion, increased wear resistance and exceptional contact fatigue strength. Inductoheat offers the most flexible solution for today’s gear needs and as tomorrow’s business changes, we develop new solutions for a more efficient hardening process resulting in reduced energy, utility and operation costs. Simultaneous Dual...

Open the catalog to page 11

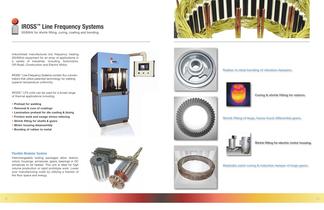

IROSS™ Line Frequency Systems 50/60Hz for shrink fitting, curing, coating and bonding. Inductoheat manufactures low frequency heating (50/60Hz) equipment for an array of applications in a variety of industries, including: Automotive, Off-Road, Construction and Electric Motor. Rubber to steel bonding of vibration dampers. IROSS™ Line Frequency Systems contain flux concentrators that utilize patented technology for yielding superior temperature uniformity. IROSS™ LFS units can be used for a broad range of thermal applications including; • Preheat for welding • Removal & cure of coatings •...

Open the catalog to page 12All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

STATISCAN II and IV

2 Pages

-

InductoScan PC HMI-PLC

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages

-

VSM-95

2 Pages