Website:

Inductoheat Europe GmbH

Website:

Inductoheat Europe GmbH

Group: Inductotherm Industries

Catalog excerpts

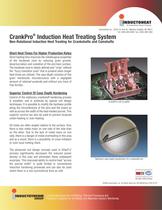

CrankPro® Induction Heat Treating System Non-Rotational Induction Heat Treating for Crankshafts and Camshafts Flexible Crankshaft Heating Solution CrankPro® systems utilize patented technology, SharP-C™ which eliminates the rotation of the crankshaft and movement of the inductor during heating and quenching cycles. This stationary heating method provides several practical and technical benefits; reduced floor space, simple operation, robust machined coil, low part distortion and minimal part growth. Features/Benefits: • SHarP-C™ Technology (Stationary Hardening Process for Crankshafts). • Short Heat times < 3 Sec. Production rates of up to 120 parts/ hour. • Robust one piece CNC machined block coil with no brazing extends coil life significantly. • Coils are CNC machined, certified and pinned in place with no adjustment necessary. • One moving part and stationary crank. • Over head gantry service. • Low distortion from 0 - 45 microns max has been observed in production and minimal part growth. • In process induction tempering. • Less wasted heat and reduced floor space. • Convertible I4 / V6 / V8. • Maintenance from outside machine/offline. CrankPro® system with gantry part handling Robust & Reliable Machined Coil Induction coils are much more robust and rigid, being CNC machined from a solid copper block without any brazed parts. This eliminates inductor distortion and hardness pattern drift. There are far fewer components involved in the novel coil design, meaning higher reliability and longer coil life because of the smaller numbers of mechanical features that could otherwise go wrong. Robust, CNC machined copper coil For more information, call 800/624-6297, email: sales@inductoheat.com or visit www.inductoheat.com

Open the catalog to page 1

Inductoheat Inc., 32251 N. Avis Dr., Madison Heights, MI 48071 Tel: (248) 585-9393 Fax: (248) 589-1062 CrankPro® Induction Heat Treating System Non-Rotational Induction Heat Treating for Crankshafts and Camshafts Short Heat Times For Higher Production Rates Short heating time improves the metallurgical properties of the hardened zone by reducing grain growth, decarburization and oxidation of the pin/main surface. The hardened zone is clearly defined and “crisp” without the “fuzzy transition zone” that is present when longer heat times are utilized. The case depth consists of fine grain...

Open the catalog to page 2All Inductoheat Europe GmbH catalogs and technical brochures

-

INDUCTOSCAN Move

2 Pages

-

Inductoforge™

4 Pages

-

IROSS

2 Pages

-

Inductoheat Europe Imagebrochure

20 Pages

-

Unicool

1 Pages

-

ENERGY MONITOR

2 Pages

-

Water Recirculating System

2 Pages

-

INSTA CHANGE

1 Pages

-

Load Frequency Analyzer

1 Pages

-

Large to Medium Bearing Race

2 Pages

-

STATISCAN II and IV

2 Pages

-

InductoScan PC HMI-PLC

2 Pages

-

STATIPOWER®SP18

2 Pages

-

STATIPOWER® SP16

2 Pages

-

STATIPOWER® SP11

2 Pages

-

STATIPOWER® SP12

2 Pages

-

STATIPOWER® SP5 & 7

2 Pages

-

iRoss

2 Pages

-

STATISCAN®

2 Pages

-

UNISCAN® II

2 Pages

-

VSM-95

2 Pages