Catalog excerpts

NETWORKS. OUR PASSION. YOUR BUSINESS. Services for productive machine networks

Open the catalog to page 1

Services for networks & for every maintenance and management strategy on the shop floor level Our team of 40 network specialists offers industrial companies throughout Europe the daily support needed to appropriately and purposefully meet every type of challenge that can arise from the operation of machine networks. increase overall system effectiveness significantly, stabilise production processes and open up access to previously unattainable potential savings. In future, the digitalisation know-how in our condition monitoring systems will not only extend to the network itself, but also to...

Open the catalog to page 2

Consulting for OT and IIT networks and integrations Condition Monitoring Systems automate the maintenance activities We extend the CMMS* to include multi-sensors (SIEDS*) and an OT security device (D*bridge) and create the basis so that installers and operators receive equal access to the data streams below the PLC. Our experts are already undertaking the field level network management for several of our most renowned customers. Working closely with the maintenance on site – via remote – together we are already developing the forward-looking network management of tomorrow today. The result...

Open the catalog to page 3

1,750 deployments of our service technicians at a total breakdown on the operator side. More than

Open the catalog to page 4

always there when it’s really urgent We have used the events of recent years as an opportunity – to review how the quality of machine networks and the opportunities for operating proactive condition monitoring have developed. In 2022, our network experts were called out to approx. 150 SOS deployments on site (in industry). The reasons for these are generally massive faults in the production process or total breakdowns, which are caused by a reactive maintenance strategy, which exceed the client’s resources and know-how. » €2.3 billion of lost profits due to reactive maintenance. 90% could...

Open the catalog to page 5

service levels for condition monitoring management systems with maintenance offer a massive economic contribution. Our

Open the catalog to page 6

Digitalisation and OT/IT integration are changing everything Due to the increasing digitalisation of the field level, sweeping changes result within the classic job descriptions. New task profiles result. The classic OT organisation not only meets its limits with regard to content but above all in terms of personnel. The new objective is to automate the core process and constantly recurring maintenance tasks economically and efficiently. Apart from production planning and control, this also severely affects maintenance. Due to the integration of OT and IT in particular, new specialists are...

Open the catalog to page 7

Which maintenance strategy is pursued in the company? A suitable condition monitoring management system can make a proactive contribution to the correction of these problems to make your production more efficient, reduce costs and automate many recurring maintenance tasks. Along the way to efficient and likewise productive maintenance – in the sense of Industry 4.0, operators of machines and plants are faced by diverse challenges: High direct and indirect maintenance costs, which can often account for more than 40% of the ongoing operating costs, poor documentation, insufficient access to...

Open the catalog to page 8

Condition-based maintenance Predictive maintenance In this maintenance strategy the component or tool is not changed until the highest degree of wear has been reached. Pursues a forward-looking approach and services machines and plants proactively. In this maintenance strategy, the suitable time and measures required for changing the component or tool is determined on the basis of the current and historical data. To this end, the actual condition of a plant is monitored continuously to determine which maintenance measures are required.

Open the catalog to page 9

Investment comparison Costs vs. benefits The condition monitoring “earnings” The example described below involves a medium-sized production plant, with 6 programmable logic controls in the food industry. potential savings can be achieved in your field level, then simply contact us. We will be pleased to assist you. If you are interested in finding out what specific Implementation without monitoring Implementation with monitoring Investment in reactive maintenance: Invest in proactive maintenance: Network SmartUp Service » Troubleshooting stress » Reduced plant availability and therefore...

Open the catalog to page 10

Costs comparison Insourcing vs. Outsourcing » Personnel recruiting » Scalable costs » The experts at your side » Create redundancies » Ability to respond fast » Costs for personnel management » Cost-effective from year 1 * Insourcing costs, for approx. 1.5 FTE, approx. 30%, of which spent on condition monitoring deployments We involve the experts in the workflow We integrate the experts into the network management » Remove problems/faults » Remove problems/faults » Servicing/maintenance » Record/evaluate NW data » Record/evaluate NW data » Recommended actions

Open the catalog to page 11

info@indu-sol.com www.indu-sol.com Certified to EN ISO 9001:2015

Open the catalog to page 12All Indu-Sol GmbH catalogs and technical brochures

-

D*BRIDGE + SIEDS

3 Pages

-

Infrastructure components

8 Pages

-

EMV Brochure

36 Pages

-

PROFIBUS Broschure

36 Pages

-

New Products Indu-Sol

7 Pages

-

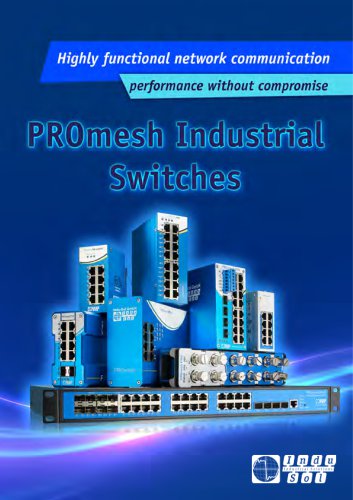

Indu-Sol PROmesh Switch Family

16 Pages