Catalog excerpts

Indu-Sol GmbH – Specialist in Industrial Networks Optimum equipotential bonding Basis for stable data communication Products Diagnosis Monitoring Training Consulting Network Services

Open the catalog to page 1

networks our passion, Your Business

Open the catalog to page 3

EMC in fieldbus-related environments – Shielding, earthing, Shield terminal EMClip® PROFINET cable +FE Multi-frequency conductor cable Mesh resistance measuring clamp EMCheck® MWMZ II Leakage current measuring clamp EMCheck® LS

Open the catalog to page 4

Shield terminal EMClip® networks our passion, Your Business Meshed equipotential bonding system on cable tray PROFINET cable EMClots® Intelligent current measuring clamp EMCheck® ISMZ I Conductor cable class 8 Motor cable SymFlex® EMV-Drive +

Open the catalog to page 5

EMC in fieldbus-related environments – Introduction Basics Currently, a new phenomenon has appeared during the search for causes of network failures. It has been noted that data communication issues are becoming more frequent in situations where the system itself does not reveal any weak points. It was the investigation of shield currents on industrial data lines that prompted the diagnostic approach to take a completely new turn. It soon became clear that the network itself was in perfect condition but was being affected by external influences that are generally referred to as ”EMC...

Open the catalog to page 6

networks our passion, Your Business Typical sources of interference In recent years, many studies have revealed ever increasing loads on equipotential bonding systems due to highfrequency currents. The causes for this increase are quickly identified by the increasing number of variable-speed drives, combined with an increasing degree of automation of machines and systems. Other typical sources of interference include power electronics, switching operations (contactors) and equipotential bonding differences. The following principles apply: Strong and higher-frequency currents, as generated...

Open the catalog to page 7

EMC in fieldbus-related environments – Basic concepts Definitions Equipotential bonding (PA) A multitude of standards and guidelines exist on this subject. Some of them repeat or even contradict each other. The objectives of equipotential bonding include the protection of people and animals against electric shock as well as electrical functions such as providing a uniform signal reference potential. A distinction is therefore made between protective bonding and functional bonding. Important standards: Leakage currents VDE 0100-540 / DIN EN 61140 (currents in PE conductors) The PE conductor...

Open the catalog to page 8

networks our passion, Your Business Reference values In order to ensure the functional safety of the automation From an economic point of view, it should be possible to perform the measurements during operation of the system. network, the EMC acceptance check – based on measurements – is an essential quality certificate for systems. The The need for carrying out the measurements is related to frequent system downtimes that are not caused by communication errors in the industrial data communication but are rather caused by disturbances due to EMC interactions. objective is to ensure...

Open the catalog to page 9

EMC – Planning for equipotential bonding Planning for equipotential bonding – Today‘s technology As explained at the outset, disturbances of industrial data communication by electromagnetic interference may occur despite all devices and components being in perfect condition. In many cases, however, these interference values are only retroactively determined by measurements. The equipotential bonding system is installed subsequently and then needs to be adapted to the machine and system environment. According to current practice, the electronic components (PLC, drives, remote I/O) are mostly...

Open the catalog to page 10

networks our passion, Your Business Planning for equipotential bonding – Tomorrow‘s technology applies to FE/BN connections of electrical equipment with regard to the equipotential bonding of the machine/system. However, it is recommended to use a minimum of two connections in order to obtain a mesh width of 20 m. In addition, all electrically conductive system components, pipes, trays and channels must be arranged and wired within the machine/system in an EMC-compatible manner in order to achieve a maximum meshing effect. All switched inductances in the system (contactors, relays,...

Open the catalog to page 11

EMC infrastructure components Conductor cables, tin-plated, extra-fine wire and stranded Application Notes on the electrochemical series Non-insulated, highly flexible copper cables are especially suitable for the small-loop low-impedance bonding systems required by EN 50310 for machines and installations using higher-frequency drive solutions (inverters). The fine-strand cable structure provides large surfaces for the transfer of higher-frequency currents. Typical interference currents in industrial environments, e.g. due to frequency inverters, are in the range up to 8 kHz, or...

Open the catalog to page 12

networks our passion, Your Business Conductor cables Conductor structure to VDE 0295 class 2 Structure (tin-plated and extra-fine wire) ■ Cross-section: 0,5 mm² - 120 mm ■ Cross-section: 0.5 mm² - 120 mm² ■ Material: Cu-ETP wire corresponding to DIN EN 13602 ■ Surface: tin-plated bare, highly flexible stranded copper cable, tin-plated shielding according to DIN 46440 Stif f tion installa Structure (stranded) Conductor structure to VDE 0295 class 5 tin-plated shielding Structure (fine-wire) ■ Cross-section: ■ Material: ■ Surface: extra-fine wire copper strand 0.14 mm² - 120 mm² Cu-ETP 1...

Open the catalog to page 13

EMC infrastructure components EmClots® fastening elements – stable and conductive Planning for equipotential bonding with foresight The use of EmClots® significantly facilitates the implementation of a distributed equipotential bonding system. A variety of components can be used for connecting, fastening and branching of bare conductor cables of extra-fine wire and stranded type. Undefined interference currents are thus prevented and uniform equipotential bonding is implemented even in long production lines. EmClots® are ideally suited for implementing small-loop low-impedance bonding...

Open the catalog to page 14All Indu-Sol GmbH catalogs and technical brochures

-

D*BRIDGE + SIEDS

3 Pages

-

Infrastructure components

8 Pages

-

Machine network services

12 Pages

-

PROFIBUS Broschure

36 Pages

-

New Products Indu-Sol

7 Pages

-

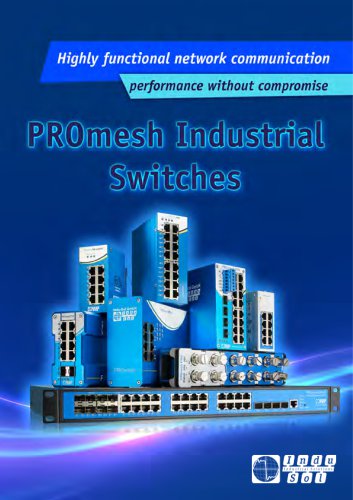

Indu-Sol PROmesh Switch Family

16 Pages