Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

TNX65 Turn-mill center for high performance machining

Open the catalog to page 1

standards in high-performance machining. Its future-oriented machine concept comprising a new, unique milling unit offers previously unexpected opportunities of integrating machining processes.This concept stands for previously unknown flexibility and productivity.The new milling unit impresses by its chip-to-chip times, such as previously only known of tool turrets.

Open the catalog to page 2

TNX65 A passion for high performance

Open the catalog to page 3

economical with The machine concept of the TNX65 has been tailored to the wide range of requirements needed by users. The result offers many advantages: ■ quadruple functional symmetry i. e. 4 identical turrets with independent Y axis, with identical tool change areas and identical number of tool stations ■ free allocation of the tool carriers to the two spindles ■ high-powered drives on main and counter spindles provide optimum metal-cutting performance ■ powerful tool drives on all turrets for perfect complete machining Less setup efforts ■ precise tool change repetitive accuracy of the...

Open the catalog to page 4

Modular system New: The milling unit Features chip-to-chip times that are as quick as with a turret. Up to 80/120 tools in the magazine are available for almost limitless machining tasks. The modular system For optimal adaptation of the machine equipment to your specific needs. The basic structure The compact machine bed made of heavily ribbed cast iron has high torsional and bending stiffness. It carries the thermo-symmetric headstock and the linear guideways for bed slides and counter spindle slides. It offers excellent vibration dampening, outstanding dynamic stiffness and high thermal...

Open the catalog to page 5

with only two turrets The TRAUB TNX65 allows you to perform a host of different machining tasks using just the basic equipment including two turrets. This is made possible because both tool carriers can be used on both the main and counter spindles. This gives you previously unknown freedom in simultaneous machining of the workpiece on the front and back. Thus, machining tasks can be planned perfectly and the resulting parts can be produced with minimum cycle times. One tool holder for all turrets and all machining directions The two-sided serration of our tool holders (TRAUB patent) allows...

Open the catalog to page 6

The turrets Owing to their 30 mm of shaft diameter, the 10 tool holder stations form a solid base when using different tools. Short setup times are achieved by using the patented TRAUB tool holder alignment or W serration. The spindles The identically designed spindles are provided as standard with hybrid bearings. This gives significantly increased service lives. The powerful motor spindles are designed in synchronous technology Automatic unloading The finished part is discharged by a gripper positioned via highly dynamic axes on the right side of the machine via a conveyor in parallel to...

Open the catalog to page 7

of our turrets Intelligent turret construction ■ the controllable turret indexing simplifies your setup procedure ■ large tool change areas and reduced risk of collision are 3-D machining ■ 4 independent sub systems of ± 40 mm Y travel each allow simultaneous drilling and milling with 4 tools on the spindles ■ X travels of up to 40 mm under the turning centre allow high-precision end-face machining up to a pitch circle of 80 mm without C axis movement achieved with our inclined bed construction and the particularly large available space ■ large tool stock by using double tool holders

Open the catalog to page 8

Simply unique the milling unit The milling unit is the highlight of the TNX65. The tool magazine with its 80/120 tool pockets and incredible chip-to-chip times stands for maximum productivity. Tool holder system: the highly compact design of the milling unit also allows simultaneous end face machining means of the turrets no restrictions for the axis movements due to the unique kinematics, i.e., same traversing range as that of the turrets unrestricted use on main and counter spindles allows processes such as turning, gear hobbing, hobbing, B axis machining etc., to be integrated powerful...

Open the catalog to page 9

Options - as varied as your requirements Tool holders: single or double fixed or driven

Open the catalog to page 11

Clearly arranged user interface with dialog technology for programming, editing, setup and operation ■ 15” Multitouch display for the use of touch functions with gesture technology or menu operation using buttons ■ Ideally equipped for Industry 4.0 - easy integration of the machine into the manufacturing environment ■ Online retrieval of manufacturing and setup information; remote access via VNC ■ Graphics-supported interactive guidance also during setup ■ Comfortable process synchronization and optimization of the program sequences of parallel machining processes ■ Visual control to avoid...

Open the catalog to page 12

Get a firm grasp on your production Additional safety device -Electronic quick retraction ■ Active on all TRAUB machines ■ Active counter control in case of malfunction ■ Response time in the millisecond range by intelligent servo amplifier ■ More effective than mechanical safety systems Programming, optimization, simulation ■ Realistic real-time simulation for shorter setup times ■ 3D workpiece display as standard feature ■ Graphical display of the working sequences ■ Visual collision check before the machine is run in '.-4Q KAHFASEN ETlRHFRjiFSUIJi ft- Fr^HiGUr-Adna/ ftm ribcn G17Y AiIh j...

Open the catalog to page 13

Working areas Milling unit Milling unit

Open the catalog to page 14

Working range Turning length Main spindle, counter spindle Bar capacity (max. bar diameter) Spindle diameter front bearing Spindle nose ISO 702/1 Chuck diameter Speed Power at 40 % Torque at 40 % C axis resolution Z axis rapid traverse (counter spindle) Compound slide Slide travel 1 Slide travel 2 Slide travel 3 Slide travel 4 Rapid traverse Turrets 1,2, 3, 4 Number of stations Cylindrical shank mounting DIN 69880 Tool drive speed max. Tool drive power max. Tool drive torque max. Milling unit Slide travel Rapid traverse Speed max. Power max. Torque max. Tool holder system Number of tool...

Open the catalog to page 15

BRAZIL // Sorocaba INDEX Tornos Automaticos Ind. e Com. Ltda. Rua Joaquim Machado 250 18087-280 Sorocaba - SP Phone +55 15 2102 6017 vendas@indextornos.com.br br.index-traub.com CHINA // Shanghai INDEX Trading (Shanghai) Co., Ltd. No.526, Fute East 3rd Road Shanghai 200131 Phone +86 21 54176637 china@index-traub.com www.index-traub.cn FINLAND // Helsinki INDEX TRAUB Finland Hernepellontie 27 00710 Helsinki Phone +35 8 108432001 pekka.virkki@index-traub.fi www.index-traub.fi FRANCE // Paris INDEX France Sarl 1A, Avenue du Quebec / Z.A. de Courtabreuf 91941 Les Ulis Cedex Phone +33 1 69187676...

Open the catalog to page 16All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

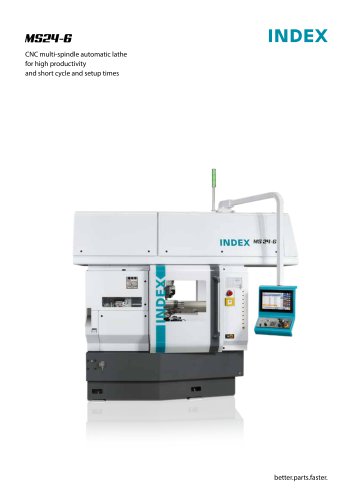

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

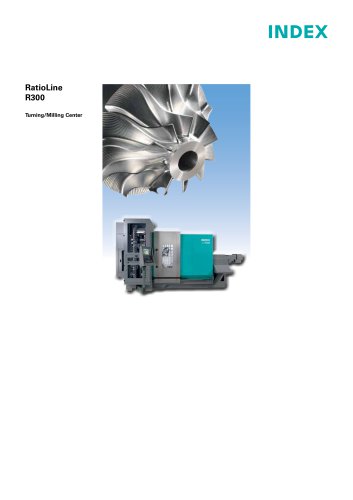

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages