Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

TNL20 Sliding / fixed headstock automatic lathe for precise and economical machining

Open the catalog to page 1

Sliding/fixed headstock automatic lathe TNL20 productive sliding and fixed headstock turning of medium and high complexity workpieces from bar stock or with an integrated robot cell The new TNL20 has two identical work spindles and two tool The work area, unique in its class, of this automatic turning turrets, each with X-, Z-, and Y-axes. And in addition, it can be machine assures with its compact foot print a very high power equipped with a front and back working attachment. density for economic production. In addition, the vertical work So this sliding and fixed headstock automatic lathe...

Open the catalog to page 2

The work area concept Simultaneous and productive machining with two tool turrets and a front and rear working attachment. The machine design • Bar capacity up to 0 20 mm • Up to three tool carriers and one back working attachment, each with Y-axis • Simultaneous machining with two, three or four tools • High tool pool for setup-friendly production • Short tool changing times by means of CNC indexing axis in the tool turrets and in the front working attachment • Very fast and energy-efficient dog clamping on the main spindle and counter spindle • Generous and process-reliable work area •...

Open the catalog to page 3

Sliding/fixed headstock automatic lathe TNL20 TNL20-9 / TNL20-9B – simultaneous and precise manufacturing with up to three tools The machine concept of the TNL20 has been systematically The machine’s crucial productivity advantage is the result of its matched to the daily requirements of the user. extraordinarily high dynamics. The newly developed machine So the kinematics of the machine allows effective and simulta- bed from gray cast iron forms the basis for utmost vibration neous machining with two or three tools. dampening properties. And the high rigidity and thermal The generous and...

Open the catalog to page 4

Sliding/fixed headstock automatic lathe TNL20 TNL20-11 with additional front working attachment – precise and even more efficient production with four tools simultaneously Control slide valve Drive shaft Material Cycle time Cycle time Cycle time

Open the catalog to page 6

The components Main and counter spindles (motorized spindles) • Bar capacity Ø 20 mm • Spindle speed 10,000 rpm • Drive power (100% / 40%) 3.0 / 5.5 kW Torque (100% / 40%) 5.73 / 10.5 / max. 17 Nm .2 • Fast material clamping, approx. 0.2 s for dog clamping • Optional: Pneumatic clamping device with 6 mm clamping stroke and clamping force programming on the operating panel Two tool turrets Indexing axis designed as interpolated H-axis 8 stations, up to 24 tools per turret can be used Compact shank mounting Ø 45 mm 20 / 20 / 40 m/min 1.0 / 2.0 kW Coolant pressure up to 80 bar, up to 120 bar...

Open the catalog to page 8

Sliding/fixed headstock automatic lathe TNL20 The workpiece discharge unit – fast, safe and gentle Flushing unit for workpieces Small workpieces weighing up to approx. 150 g and up to 20 mm in diameter can be flushed out easily, quickly and gently from the counter spindle through the indexing shaft of the lower tool turret by means of an optional flushing unit. A ring sensor monitors and confirms the safe discharge of the workpieces to the right into a workpiece container or onto an optional part conveyor belt. Workpiece removal unit The workpiece removal unit (servo linear axis in...

Open the catalog to page 10

Integrated robot cell Intelligent automation – even more flexibility and efficiency With the optional robotic cell, blanks and/or finished parts can be supplied and discharged quickly, safely and flexibly. The robot cell is integrated ergonomically into the machine. It can be moved easily to the left during the setup process, allowing unobstructed access to the work area of the machine. During production, the robot cell is fixed in front of the machine’s work area. The robot then accesses the work area via the sliding guard of the machine, which opens automatically behind the robot cell....

Open the catalog to page 12

^XIBB V panelThe cockpit for easy integration of the machine in your business organization. Focus on production and control - Industry 4.0 included. The iXpanel operating concept provides access to networked production. With iXpanel your staff always has all relevant information for efficient production right at the machine. iXpanel is already included in the standard and can be individually extended. You can use iXpanel as you want it for your business organization - that's Industry 4.0 tailored to your needs. Future-proof. TRAUB TX8i-s V8 optimally integrates the iXpanel functionalities....

Open the catalog to page 14

Order documents Customer data Setup sheet Information center Remote access User management Technology computer • WinFlexIPS • WinFlexIPS Plus • Custom applications Programming help + many more standard features

Open the catalog to page 15

Sliding/fixed headstock automatic lathe TNL20 Work area TNL20-9 Tool turret 1 CSP Turning with guide bush Turning without guide bush Rear end machining unit 567,5 Turning with guide bush Turning without guide bush * Dimension without robot cell ** Dimension with robot cell Installation Chart

Open the catalog to page 16

Max. Z-travel Sliding headstock machine/fixed headstock machine mm Max. rapid traverse rate Z m/min Upper tool turret Tool mountings Number Live tools Number Turning tool cross-section mm Rapid traverse rate X / Y / Z m/min Swivel angle B axis Deg. Lower tool turret Tool mountings Number Live tools Number Turning tool cross-section mm Rapid traverse rate X / Y / Z m/min Back working attachment Tool mountings Number Counter spindle Max. spindle capacity mm Rapid traverse rate X / Z m/min Cooling lubricant unit (basic unit) Pump pressure bar Pump capacity 3 / 8 bar l/min Machine dimensions...

Open the catalog to page 17

Sliding/fixed headstock automatic lathe TNL20 Work area TNL20-11 Tool turret 1 Front working attachment Turning with guide bush Turning without guide bush Rear end machining unit 2,91° Front working attachment Turning with guide bush Turning with guide bush Turning without guide bush Turning without guide bush Rear end machining unit

Open the catalog to page 18All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

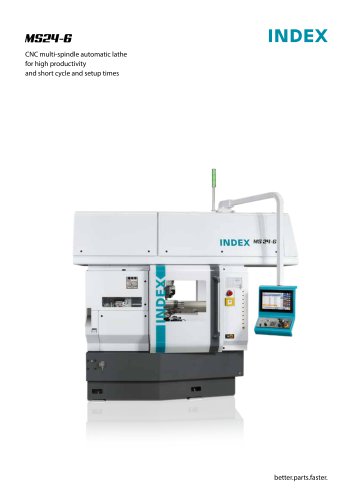

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

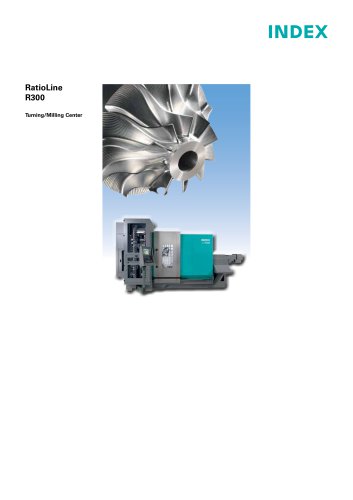

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages