Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

INDEX Turn-mill center for flexible complete machining better, parts, faster.

Open the catalog to page 1

A new dimension in milling and turning With the R series, INDEX is setting the standard for a new generation of turning/milling centers. Two motorized milling spindles perform machining in two independent sub-systems, including 5-axis machining. Both heavy-duty roughing operations and highly accurate fine-turning operations can be performed simultaneously on the main spindle and counter spindle. This parallel use increases productivity significantly compared to conventional designs. New design solutions for optimum stiffness, thermal and dynamic stability, and vibration damping also provide...

Open the catalog to page 2

Due to intelligent kinematics with an efficient arrangement of axes, a trend-setting machine concept has emerged that also facilitates comprehensive complete machining operations. The idea: A vertical machine arrangement in which the main spindle moves in the Z direction, the counter spindle in the X and Z directions, tool carrier 1 in the X, Y, and B directions, and tool carrier 2 in the Y and B directions. Solid construction with impressive kinematics The result: A design with two independent sub-systems, exceptional stiffness between moving components and machine bed, as well as...

Open the catalog to page 3

Circular guide - from the center of the machine bed INDEX Circular guide • High stiffness • Transmission of force via short lever arms • High dynamic response • Best damping and guiding properties During development of the R series, emphasis was placed on achieving a high degree of stiffness, thermal and dynamic stability, and vibration damping. For this reason, a vertical cast machine bed with a heavily ribbed, enclosed modular design was chosen. The motorized milling spindles are placed in the center of the machine and are operated freely and wearfree in the Y- and B-axes via hydrostatic...

Open the catalog to page 4

The magazine - all tools on board Two separate shuttle units independently supply the two motorized milling spindles with the tools required in each case from the tool magazine. With a maximum of 120 tool pockets, the R200 has a large tool set. Chip-to-chip time of 4 seconds contributes to minimizing secondary processing times. At a glance • 80/120 tool stations (HSK-T40 holder) • Minimum load cycles; Chip-to-chip time only 4 s • Simultaneous and independent changes at both milling spindles possible • High degree of functional reliability due to standard tool magazine with chain design...

Open the catalog to page 5

For years, INDEX has viewed the efficient use of energy and resources as a key requirement in its machine development activities. Therefore, today all machines already conform to the principle of reduced energy consumption with simultaneous improvement in environmental compatibility. Design experience, such as measurements on machines in the field, form the basis for meeting or even surpassing requirements regarding energy/resource efficiency sustainably, also in the future. Weight reduction: • Reduction of energy consumption Simulation programs enable minimization of weights of moving...

Open the catalog to page 6

Simple tool selection The programmer decides which new tool is to be provided and when - separately and independently for both tool carriers. Simultaneous tool change is also possible. The tool pool in the magazine can be used by both tool carriers without restriction. A control designed according to user's wishes Reliable handling The INDEX C200-4D sl control is based on the field-proven SIEMENS SINUMERIK S840D Solution Line, paired with drives from the Easy to program A large number of powerful user cycles ensure: • Simple and fast programming • Field-oriented applications • Tested and...

Open the catalog to page 7

Technical data Working area mensions Di +Y2 160 6.3) Main spindle, counter spindle Unit Spindle diameter in front bearing mm (inch) Spindle nose ISO 702/1 Size Chuck diameter mm (inch) C-axis resolution Degrees Feed drive of main spindle Minimum distance for collet mm (inch) Slide travel of Z-axis mm (inch) Rapid traverse rate m (inch)/min Feed drive of counter spindle Minimum distance for collet mm (inch) Slide travel of Z-axis mm (inch) Slide travel of X-axis mm (inch) Rapid traverse rate X, Z m (inch)/min 100 (3.9) 390 (15.4) R200 with SBL bar loading magazine 2380 (93.70) 3470 (136.62)...

Open the catalog to page 8

BRAZIL I Sorocaba INDEX Toriios Automaticos Ind. e Com. Ltda. Rua Joaquim Machado 250 18087-280 Sorocaba - SP Phone +55 15 2102 6017 info@index-traub.com.br www.index-traub.com.br CHINA I Shanghai INDEX Trading (Shanghai) Co., Ltd. No. 526, Fute East 3rd Road Shanghai 200131 Phone +86 21 54176637 info@index-traub.cn www.index-traub.cn CHINA I Taicang INDEX Machine Tools (Taicang) Co., Ltd. 1-1 Fada Road, Building no. 4 Ban Qiao, Cheng Xiang Town 215413 Taicang, Jiangsu Tel.: +86 512 5372 2939 info@index-traub.cn www.index-traub.cn DENMARK I Langeskov INDEX TRAUB Danmark Havretoften 1 5550...

Open the catalog to page 9All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

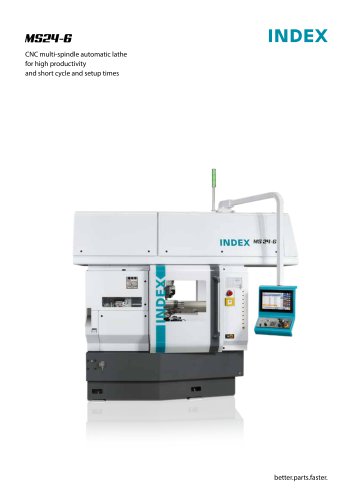

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

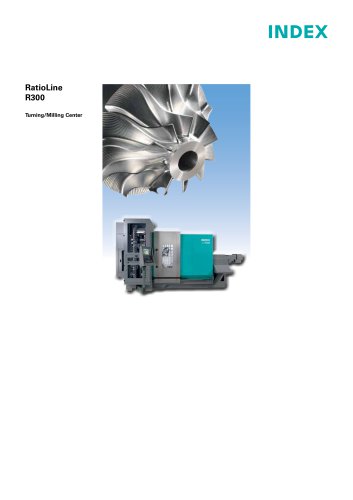

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages