Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

MS40-8 CNC multi-spindle automatic lathe for high-productivity manufacturing

Open the catalog to page 1

INDEX CNC multi-spindle automatic lathe More productive with 8 spindles! With the totally configurable INDEX MS40-8, we offer a All aspects of the INDEX MS40-8 were developed using machine concept that meets all requirements and the most state-of-the-art manufacturing technologies. stringent demands. Eight main spindles, up to two swiveling synchronous Generously dimensioned and freely accessible, the work spindles, and up to eighteen tool carriers, which can be area minimizes setup cost, especially for changeovers. configured in XYZ, enable high-productivity manufacturing. Unhindered chip...

Open the catalog to page 2

Designed to meet precise user requirements − the concept behind the INDEX MS40-8 Machine design • Freely accessible work area, making setup particularly easy • Highly dynamic slide with sliding guide (X axis) • Non-wearing Z axis, due to quills with hydrostatic support • Front-opening machine for bar machining • Chuck part machining with robot loading and unloading • Directed part discharge through linear handling • Extremely fast swiveling synchronous spindles with C axis • Swing arm is locked in machining position by three-piece Hirth coupling ensuring maximum rigidity • Maximum of 7...

Open the catalog to page 3

Our hallmark - the spindle drum The compact spindle drum ensures maximum precision in each position through the use of a three-piece Hirth coupling. The basis is composed of eight fluid-cooled motorized spindles integrated in the spindle drum. Infinitely variable speed control, compact design, low maintenance and the latest synchronous drive technology provide a guarantee for high-precision workpieces. Independent speeds During machining, it is always possible to program the optimum speed, which can still be varied during cutting, for each spindle position and each cutting edge of the tool....

Open the catalog to page 4

The double four-spindle machine - an interesting upgrade option • Additional part production time reduction due to simultaneous manufacturing of 2 workpieces • 18 tool carriers with 1 or 2 axes (optionally also Y axis) • 2 swiveling synchronous spindles and up to 7 tools for face machining, 4 of them live (per spindle) Versatility is a strength of the INDEX MS40-8. Whether complex parts or manufacturing methods are involved - almost anything is possible • A maximum of 18 tool carriers with 1 or 2 travel axes • Y axis (optional) • 1 or 2 swiveling synchronous spindles • Variable use of tool...

Open the catalog to page 6

Simply more possibilities The work area – virtually limitless machining capabilities for each Machining examples 1. xternal turning – E internal turning spindle position The tool carrier arrangement in the work area, without longitudinal sliding block, allows more than one tool to be used on each spindle. Available machining operations are therefore limited only by the tool holder. As a result, external turning you can specify all production steps in all spindle positions. Another advantage: They have free chip fall. 3. External live – internal live understand it Maximum productivity and...

Open the catalog to page 8

Valve sleeve Mounting

Open the catalog to page 9

Linear shuttle with intermediate gripper for directed parts discharge from spindle position 8 Very rapid, position-oriented removal by a linear and rotary motion. The workpiece is transferred first from the synchronous spindle to the intermediate gripper. The linear shuttle then takes the workpiece from the intermediate gripper and passes it to the external handling system. This process takes place during secondary processing time. Parts feed and discharge by 6-axis robot via the swivel disk interface to the external handling system The workpiece handling system for chuck parts and bar...

Open the catalog to page 10

Directed parts removal from synchronous spindle onto the internal conveyor belt Axially-directed discharge by gripper and linear cylinder transfers parts from the synchronous spindle in position 8 to the internal conveyor belt for parts that may not be ejected. 3-axis linear shuttle for directed parts removal from the synchronous spindle Damage-free and position-oriented delivery of components is provided from the synchronous spindle in position 8, or positions 7 and 8, to the external handling system at the front of the machine. All 3 axes of the machine-integrated handling system are...

Open the catalog to page 11

■■■■■ panel IIIHThe cockpit for easy integration of the machine in your business organization. Focus on production and control - Industry 4.0 included. The iXpanel operating concept provides access to networked production. With iXpanel, your staff always has all relevant information for efficient production right at the machine. iXpanel is already included as standard and can be individually extended. You can use iXpanel as you want it for your business organization - that's Industry 4.0 tailored to your needs. Future-proof. iXpanel integrates the latest control generation SIEMENS S840D sl...

Open the catalog to page 12

Maintenance & care User management Technology computer Programming help VirtualPro Custom Programming applications + many more standard features

Open the catalog to page 13

Technical data Work spindles Tool carrier Synchronous spindle Speed Nmax. Speed Nrated Swiveling angle of synchronous spindles Number of tools for rear-end machining Back-boring slides 7.3 / 8.3 (optional) Tool carriers for rear-end machining Slide travel X Number of tools for rear-end machining Back-boring slides 7.4 / 8.4 (optional) Tool carriers for rear-end machining Number of tools for rear-end machining Machine dimensions Length x width x height Connected power Options Polygon turning, hobbing, tool monitoring, Y axis, transmit function 4707 Loading magazine

Open the catalog to page 14

BRAZIL // Sorocaba INDEX Tornos Automaticos Ind. e Com. Ltda. Rua .Joaquirn Machado. 250 18087-280 Sorocaba - SP Phone +55 15 2 102 60.17 vendas@indextornos.com.br br.index-traub.com CHINA ■■■■ Shanghai INDEX Trading (Shanghai) Co., Ltd. No.526, Fute East 3rd Road Shanghai 200131 Phone +86 21 54176637 china@index-traub.com www.index-traub.cn CHINA ■■■ Dalian INDEX DALIAN Machine Tool Ltd. 17 Changxin Road Dalian I I 6600 Phone +86 4 | | 876I 9788 dalian@index-traub.com www.index-traub.cn DENMARK " Langeskov INDEX TRAUB Danmark Havretoften 1 5550 Langeskov Phone +45 30681790...

Open the catalog to page 16All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

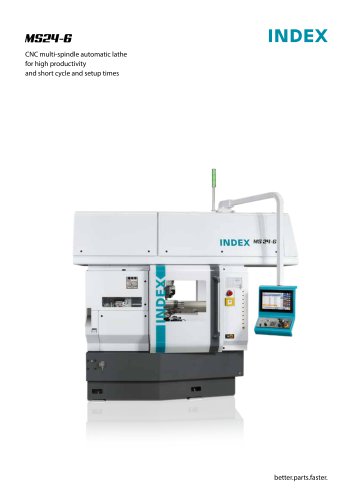

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

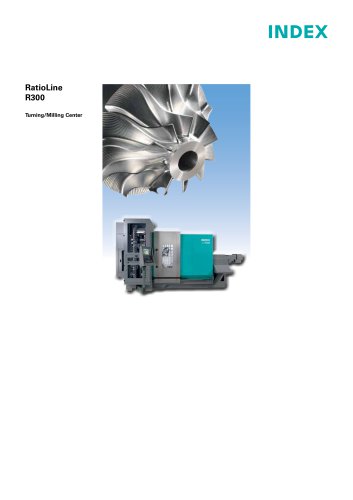

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages