Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

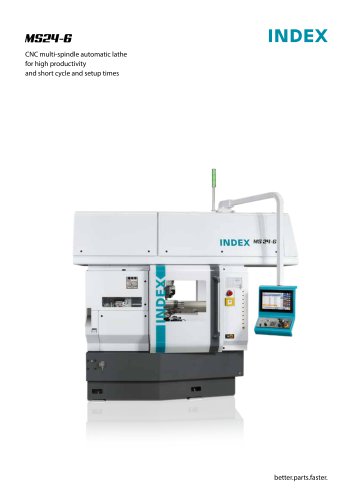

MS24-6 CNC multi-spindle automatic lathe for high productivity and short cycle and setup times

Open the catalog to page 1

INDEX CNC multi-spindle automatic lathe: high level of flexibility, shorter setup and cycle times With the INDEX MS24-6 multi-spindle automatic lathe, which The INDEX quick-clamping system, patented W-serration, and can be configured according to manufacturers' specific ergonomic open-front work area minimize setup times. needs, INDEX is presenting a machine concept that meets Maximum dynamic response and minimum non-productive stringent requirements and the highest demands. times also contribute to low part costs. Six main spindles, up to two swiveling synchronized spindles, and up to...

Open the catalog to page 2

Flexible, highly productive, and quick to set up – the machine concept of the INDEX MS24-6: • Highly-dynamic cross slide with sliding guide (X axis) • Non-wearing Z axis thanks to quills with hydrostatic support • Freely accessible working area, making setup particularly easy • Fast tool setup with the INDEX quick clamping system and its W-serration interface • Extremely fast swiveling synchronized spindles with C axis - the swivel arm is locked in its working position by a threepiece Hirth coupling providing maximum rigidity • Up to 6 tools for rear end machining per swiveling synchronized...

Open the catalog to page 3

Our hallmark: the spindle drum The compact spindle drum ensures maximum precision in each and every position through the use of a Hirth coupling. The core is composed of six fluid-cooled motorized spindles integrated in the spindle drum. An infinitely variable speed range, high tractive force, compact design, low maintenance, and the latest synchronous drive technology - these are the criteria that make an INDEX CNC multi-spindle automatic lathe stand out. Workpiece clamping can be achieved both by push/pull or chuck clamping. This opens up a wide range of possibilities for raw part feeding...

Open the catalog to page 4

Precise, fast, and flexible Versatility is a strength of the INDEX MS24-6. Whether complex or more simple parts are involved or even varying processes, –anything is possible • A maximum of 12 tool carriers with 1 or 2 travel axes • Y axes (optional) • 1 or 2 synchronized spindles • Variable use of tool carriers for internal and external machining • Use of several tools per tool carrier possible • Cross machining with live tools • C axis and polygon turning for extended fields of application Rear-end machining with swiveling synchronized spindle • Up to 6 tools, 2 of which are live • Fast...

Open the catalog to page 6

The tool holders Tool holder change: 50% faster setup times The INDEX MS24-6 succeeds in further simplifying various setup tasks. Each cross slide now has a W-serration interface, which significantly facilitates the µm-accurate alignment of the tool holder and prevents its misalignment. The operator can preset the tool holder externally, place it on the slide, and fix it in position using the newly developed INDEX quick clamping device. All that is then needed is a quick turn with the wrench and the holder is ready to use. Thanks to this plug & play approach, the holder is changed in just...

Open the catalog to page 7

Simply more possibilities The work area – virtually limitless machining capabilities in each spindle position The tool carrier arrangement in the work area, without longitudinal sliding block, allows more than one tool to be used on each spindle. Available machining operations are therefore limited only by the tool holder. The result is that all production steps in all spindle positions can be freely defined. Another advantage: They have free chip fall. Performance as we understand it Maximum productivity and cost-effectiveness of multi-spindle automatic lathes, combined with the precision...

Open the catalog to page 8

Milling Milling with live tools in the following variants: • Disk milling cutter in conjunction with C axis operation (transmit function) • End milling cutter in conjunction with Y axis operation • Plunge milling (see j diagram) Gear cutting, gear hob-bing • Coupled with electronic precision • Maximum stability • Teeth in correct position relative to other surfaces or shaped elements • Any angular offset can be programmed • Greater tool service life as a result of shifting with Y axis Elliptical deburring of cross-drilled holes Uniform deburring (even chip removal) of cross-drilled holes...

Open the catalog to page 9

Workpiece handling systems Stationary workpiece removal device with integral parts conveyor The workpieces fall onto the internal conveyor belt through a chute and are then deflected 90° by a second chute to reach an external conveyor belt. Position-aligned workpiece removal with integral parts conveyor The workpieces are removed from position 6 by the synchronized spindle and are aligned in position to the internal conveyor belt for parts that are not to be ejected. Position-aligned workpiece removal with intermediate gripper and linear shuttle Very rapid, damage-free, position-oriented...

Open the catalog to page 10

■■■■■ panel IIIHThe cockpit for easy integration of the machine into your business organization. Focus on production and control - Industry 4.0 included. The iXpanel operating concept provides access to networked production. With iXpanel, your staff always has all relevant information for efficient production right at the machine. iXpanel is already included as standard and can be individually extended. You can use iXpanel just as you require it for your business organization - that's Industry 4.0 tailored to suit your needs. Future-proof. iXpanel integrates the latest control generation...

Open the catalog to page 12

Order documents Customer data Workpiece counter Production status Setup sheet Virtual machine 3D simulation Information center Maintenance & care User management Technology computer Programming help VirtualPro programming studio Custom applications + many more standard features

Open the catalog to page 13

Synchronized spindle swivel angle degrees 120 (157) Max. number of tools for rear-end machining 6 Back-boring slides 1+2 (optional) Tool carriers for rear-end machining 1 / 2 Number of tools for rear-end machining 3 Dimensions, mass, and connected power (at maximum equipment level, without bar guide or loading magazine) Connected power Controller Siemens S840D Solution Line, with teleservice, spindle stop, C-axis as standard Polygon turning, gear hobbing, tool monitoring, Y-axis, transmit function Speed limitations are necessary, depending on bar diameter, bar guide, and workpiece clamping.

Open the catalog to page 14All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

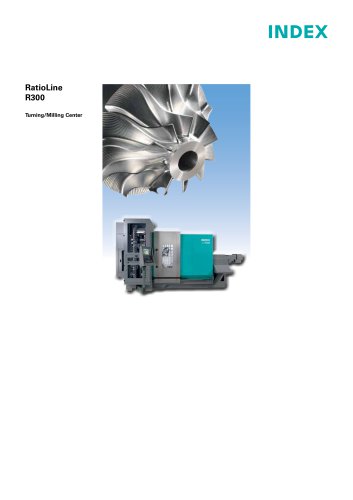

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages