Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

MSW-B MS1B-B PLUS CNC-Multi spindle turning machines for high productivity better, parts.faster.

Open the catalog to page 1

INDEX MS16-6 / INDEX MS16-6 plus CNC multi-spindle machine: More dynamics, less secondary times! The INDEX MS16-6 / INDES MS16-6 plus combines the flexi- can be managed with the ease of an ultra-modern open-front bility of modern INDEX CNC multi-spindle technology with INDEX CNC multi-spindle machine. the familiar productivity of cam-controlled machines. With 5 Shortest possible changeovers, ultra-high dynamics and low- extremely rigid CNC grooving slides, optionally also drilling est secondary times are the basis of minimal cost per part. slides instead of grooving slides, and further...

Open the catalog to page 2

Open front, flexible and productive – the machine design of the INDEX MS16-6 Extremely high power density for maximum production output with minimum footprint • Freely accessible and setup-friendly work area • Grooving or drilling slide for maximum cutting performance with minimum machining time • Quick tool setup by INDEX W-serration • Spindle drum with individual drives of the work spindles • Cross-slide for flexible complete machining • CNC cutoff slide with extended stroke for rear end machining • Max. 2 highly dynamic synchronous spindles with extremely short acceleration and...

Open the catalog to page 3

INDEX MS16-6 / INDEX MS16-6 plus The core – Top precision from INDEX Our hallmark – the spindle drum Independent speeds The compact spindle drum ensures maximum precision in During machining, it is always possible to program the opti- each position through the use of a three-piece Hirth coupling. mum speed, which can still be varied during cutting, for each The core is composed of 6 fluid-cooled motorized spindles spindle position and each cutting edge of the tool. The result integrated in the spindle drum. An infinitely variable speed is optimum chipping, maximum surface quality, short...

Open the catalog to page 4

INDEX MS16-6 / INDEX MS16-6 plus Impressively fast and flexible With dynamics and numerous machining options at low unit cost • A maximum of 12 tool carriers with 1 or 2 travel axes • Max. 2 fast synchronous spindles for rear end machining • Several tools per cross-slide possible • Variable use of tool carriers, internal-external, stationary or driven • C-axis machining possible in every spindle position • Polygon turning and other machining options INDEX MS16-6 integrated bar feeder for even shorter cycle times Configuration as a single synchronized machine Configuration as a double...

Open the catalog to page 6

INDEX MS16-6 / INDEX MS16-6 plus Polygonal turning Polygonal turning is possible in longitudinal and grooving processes, even in high-alloy materials Example: hexagonal turning i = 2:1, referring to the speed ratio of the cutter head to the workpiece Milling Milling with driven tool, also in conjunction with C-axis mode (Transmit) Elliptical deburring of cross-drill holes Uniform deburring (even chip removal) of cross-drill holes based on interpolation of the C-axis, X-axis, and Z-axis with driven tool.

Open the catalog to page 8

Simply more possibilities The work area—almost limitless machining capa- Machining examples bilities in each spindle 1. External copy turning – Internal drilling The tool carrier arrangement in the work area allows unrestricted use of several stationary or live tools – also for external machining – on each spindle. The possible Internal turning machining operations are thus limited only by the tool holder. As a result, you can specify all production steps in all spindle positions. Another advantage: unhindered chip flow. External turning Performance as we understand it Maximum productivity...

Open the catalog to page 9

INDEX MS16-6 / INDEX MS16-6 plus Workpiece handling systems 3-axis-linear shuttle for directed parts removal Damage-free, rapid and position-oriented parts removal by a linear and rotary motion. The workpiece is transferred from the synchronous spindle in position 6 to the external handling system. Fixed system parts removal Rapid parts removal by a fixed slide with pneumatic chip protection in spindle position 6 Pneumatic parts removal Adjustable parts removal with a pneumatic lift in spindle position 6

Open the catalog to page 10

The cockpit for easy integration of the machine in your business organization. Focus on production and control – Industry 4.0 included. The iXpanel operating concept provides access to networked production. With iXpanel your staff always has all relevant information for efficient production right at the machine. iXpanel is already included in the standard and can be individually extended. So you can use iXpanel as you want it for your business organization – that’s Industry 4.0 tailored to your needs. Future-proof. iXpanel integrates the latest control generation SIEMENS S840D sl. Use...

Open the catalog to page 12

INDEX W4s if Tjnsrn «arof mmsh Fll nsfirsumi STANDARD included as standard OPTION Industry 4.0 features m Setup sheet Order documents Customer data Workpiece counter Production status Virtual Machine 3D simulation Information center Maintenance & care User management Programming help VirtualPro Custom Programming applications + many more standard features

Open the catalog to page 13

Working spindles Max. bar diameter mm Integr. bar feed in position 6 and / or 1 / stroke mm Tool carrier / cross slide max. Slide travel X mm Tool carrier / cross slide max. Slide travel X mm Tool carrier / drilling slide max. Slide travel Z mm Tool carrier / cutoff slide max. Slide travel X mm Tool carrier / cutoff and back-boring slide max. Slide travel X mm Number of tools for rear end machining / synchronous spindle or Dimensions, weight and connection values (for maximum configuration level, without bar guide or loading magazine) Power consumption Control INDEX C200 sl (based on...

Open the catalog to page 14

Working spindles Max. bar diameter mm Tool carrier / cross slide max. Slide travel X mm Tool carrier / cross slide max. Slide travel X mm Tool carrier / drilling slide max. Slide travel Z mm Tool carrier / cutoff slide max. Slide travel X mm Tool carrier / cutoff and back-boring slide max. Slide travel X mm Number of tools for rear end machining / synchronous spindle or Dimensions, weight, and connection values (for maximum configuration level, without bar guide or loading magazine) Power consumption Control INDEX C200-4D (based on Siemens S840D sl) with Teleservice feature, spindle stop,...

Open the catalog to page 15All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS22-8

16 Pages

-

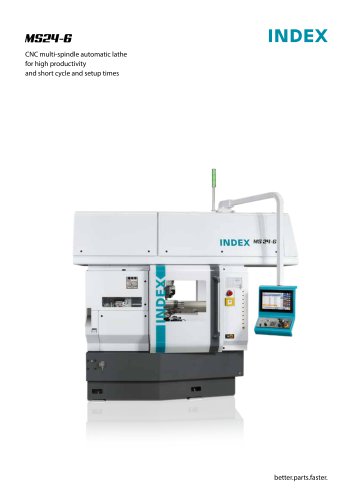

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G200.3 / INDEX G220

13 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

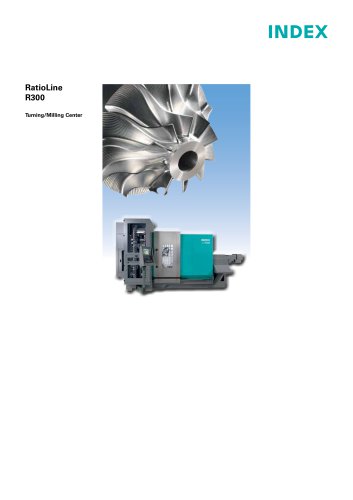

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages