Website:

INDEX Drehmaschinen

Website:

INDEX Drehmaschinen

Group: Index Group

Catalog excerpts

G200.3, G220 Turn-mill centers for high productivity and flexibility better.parts. faster.

Open the catalog to page 1

New dimensions in turning and milling The INDEX G200/G220 is an innovative turn-mill center in and thus for excellent machining results with high productiv- The large work area is unique in this class and impresses with a class of its own—especially when it comes to efficient ity. Three tool carriers with a tool pool of up to 169 tools pro- its sophisticated features that allow simultaneous machining • Identical main and counter spindles production of small to medium-sized workpieces with high vide maximum flexibility for complete machining of complex using all three tool carriers with no...

Open the catalog to page 2

Best performance for applications in the automotive, aerospace, and machinery industries INDEX provides optimal solutions for flexible and efficient production. Its engineers have integrated years of experience leveraged from many industries into the product development process. Products and processes are then tailored to specific customer needs through feasibility Motor housing Steel Ø 98 mm x 125 mm Output shaft Steel Ø 68 mm x 180 mm studies, efficiency analyses, and, above all, close collaboration with the customer. INDEX products are modular in design and highly flexible, giving...

Open the catalog to page 3

Complete machining based on a modular system The modular system in this series offers a wide range of The INDEX G220 features a powerful motor milling spindle options. Up to 3 tool carriers can be integrated into the work capable of simultaneous 5-axis machining. area, and all of them can be equipped with a Y axis. The work area offers ample space to machine any kind of The ergonomic setup and operating concept played a major workpiece, accommodating parts up to a length of 900 mm. The powerful main and counter spindles are designed for bar All the relevant components are easily accessible...

Open the catalog to page 4

The components Main and counter spindles Upper and lower turret steady rests (optional) • Upper steady rest clamping range: 6-70 mm • Lower steady rests clamping range: 6-70 mm Upper turret with 12 stations (INDEX G200) Workpiece handling unit for single gripper (optional) • 12 live stations, each VDI 30 with W-serration • Integrated 2-axis workpiece handling unit • X axis: 260 mm, rapid traverse rate: 30 m/min • Y axis: +80/-60 mm, rapid traverse rate: 20 m/min • Z axis: 1,020 mm, rapid traverse rate: 50 m/min Lower turrets with 12 stations each Workpiece handling unit for double gripper...

Open the catalog to page 5

Large degrees of freedom in the working area for a wide range of machining options INDEX G220 Simultaneous machining with 3 tools for maximum productivity INDEX G220 Use of tools up to 300 mm long in the motor milling spindle, e.g., for deep-hole drilling applications with the highest precision INDEX G200 Turret steady rests provide for flexible shaft machining INDEX G200, G220 Dipping the lower tool carriers out of the way maximizes freedom from collisions

Open the catalog to page 6

Tool magazine with up to 103/13 tions HSK-T63 / H Work area Vertical walls for optimum chip flow Motor milling spindle HSK-T63 or HSK-T40 Y-B quill with torque motor for higl precision Workpiece handling unit 2-axis/3-axis with single or double gripper Work area with turning length 900 mm Tool turret 12 tool locations each / VDI30/7,500 rpm/ 9 kW/20 Nm (25% DC) Optional: turret steady rest/15 tool locations/VDI 25 Mineral cast bed in monoblock design for excellent rigidity and thermal stability Turret slides with linear axes: Y +/-50 mm / X 180 mm

Open the catalog to page 7

The cooling concept: efficient use of energy Integrated automation solutions for efficient production Removal of finished parts The integrated workpiece (or feeding) using a work- handling unit is available as shaft or flange parts cooling principles: unloading, as well as for the removal of remnants. The • Targeted heat dissipa- system is designed for parts • Climate-neutral dissipa- The INDEX cold water for production hall heating dissipation/climate control are cooled directly with heat loss energy in a cen- energy, the INDEX cold tral location, where it can water interface provides a...

Open the catalog to page 8

Robot cell Intelligent automation—even more flexibility and efficiency With the iXcenter robot cell, blanks and finished parts can be fed and discharged quickly, safely and flexibly. The overall sequence between the machine and the robot cell is created using predefined macros in the NC program. Work area access is provided to the robot via the working area door that opens and closes automatically. The unit's modular design offers the flexibility to integrate various processes. Accessible spindles and tool carriers on the iXcenter make you best prepared to set up your machine. They also...

Open the catalog to page 9

The cockpit for easy integration of the machine in your business organization CUSTOMER Focus on production and control—Industry 4.0 included The iXpanel operating concept provides access to networked production. With iXpanel, your operators always have all relevant information for efficient production right at the machine. iXpanel is included with the standard version and can be enhanced with custom options. You can use iXpanel just as you require it for your business organization—that’s Industry 4.0 tailored to suit your needs. iXpanel integrates the latest control generation SIEMENS...

Open the catalog to page 10

INDEX G220 work area (with motor milling spindle at top) Dimensions in mm 85 90 INDEX G200 work area (with tool turret at top) Dimensions in mm min. 120

Open the catalog to page 11

Technical data Installation plan for INDEX G200/G220 Chip conveyor at right and workpiece handling unit Turning length Main spindle and counter spindle Spindle clearance Spindle nose ISO 702/1 Chuck diameter Upper tool carrier Motor milling spindle Tooling system X slide travel, rapid traverse rate, feed force Y slide travel, rapid traverse rate, feed force Z slide travel, rapid traverse rate, feed force B axis swivel range, rapid traverse rate Lower tool carrier, left/right Number of stations (live) X slide travel, rapid traverse rate, feed force Y slide travel, rapid traverse rate, feed...

Open the catalog to page 12All INDEX Drehmaschinen catalogs and technical brochures

-

INDEX MBL76

3 Pages

-

INDEX MS16-6 & INDEX MS16-6 Plus

16 Pages

-

INDEX MS22-8

16 Pages

-

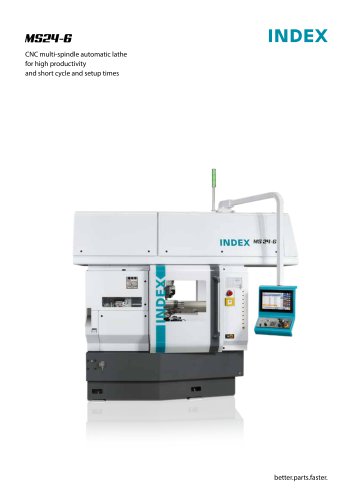

INDEX MS24-6

16 Pages

-

INDEX MS32-6

16 Pages

-

INDEX MS40-6

16 Pages

-

INDEX MS40-8

16 Pages

-

INDEX MS52-6

9 Pages

-

INDEX G300 / G320

13 Pages

-

INDEX G400 / G420

13 Pages

-

INDEX G500 / G520

11 Pages

-

INDEX R200

9 Pages

-

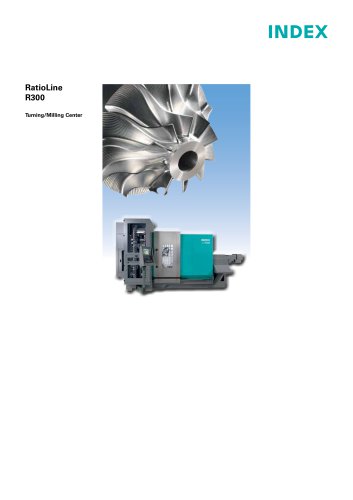

INDEX R300

16 Pages

-

TRAUB TNX200 / TRAUB TNX220

13 Pages

-

TRAUB TNX65

16 Pages

-

INDEX C200

11 Pages

-

INDEX C100

11 Pages

-

INDEX ABC

11 Pages

-

TRAUB TNA500

11 Pages

-

INDEX B500

11 Pages

-

INDEX B400

11 Pages

-

TRAUB TNA400

11 Pages

-

TRAUB TNL20

20 Pages

-

TRAUB TNL32

13 Pages

-

TRAUB TNL32 compact

11 Pages

-

TRAUB TNL12

9 Pages