Catalog excerpts

Specialists of Precision Gundrilling Gundrill tool Gundrill tool MFT 750 /6 CR Drilling diameter range min-max Drilling depth max. (Ø 1,5 - 3 mm) Drilling depth max. (Ø 3 - 6 mm) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. I.M.S.A. srl - Via Don G. dell’Acqua, 2/D - 23890 Barzago (Lc) - Italy Tel. +39 031.860444 - info@imsaitaly.com - www.imsaitaly.com MACHINES FOR CENTERLINE DRILLING OF CYLINDRICAL PARTS Drilling diameter range min-max Drilling depth max. Workpiece counter-rotation Drilling spindle IMSA Deep Hole Drilling Machines for centerline drilling: a series of custom-tailored machines IMSA“MFT”Deep Hole Drilling Machines are dedicated to cylindrical parts such as transmission housings, cam shafts, gear shafts, injectors, lubricators, couplings, valves, drive valves ... in general, all solids of revolution with a deep drilling in their axis. The automatic gun drilling machines of IMSA series MFT are customized for drilling depth, diameters, number of spindles; our range starts from machines for small lots to highproductivity lines. We also propose different solutions for automated load, as a completion to the supply. Single-spindle Gundrill tool Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Gundrill tool MFT 750 /2T CR MFT 1500 /2T CR Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Drilling heads Oil pressure max. Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Gundrill tool Drilling diameter range min-max • deep hole drilling method “BTA/STS” for our MFTB series The BTA Drilling Method Learn more at: https://www.imsaitaly.com/en/articles/the-deep-drilling-process Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindles 2x Drilling heads Oil pressure max. Single-spindle BTA-STS MFTB 1000 /51 CR MFTB 1500 /51 CR MFTB 2000 /51 CR • deep hole drilling by “gun drill tool” for our MFT Series Gundrill tool The advantages of IMSA centerline deep drilling machines IMSA machines for centerline drilling of round workpieces use two different drilling methods according to different diameters: Gundrill tool Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. • max. structure rigidity and drilling tool height always at zero; • specific IMSA functions for deep drilling process control; • autofocus movable steadyrests for an optimal tool guide during the drilling operation; • accurate oil management, by automatic system for oil cooling and filtering, as standard equipment; • depending on machine model; the counter-rotation of the workpiece in respect of the tool, gives a better drilling concentricity as a result; • on request, solutions with independent drilling units; • auto-loading systems are available on request Single-spindle BTA-STS Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Single-spindle BTA-STS Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Single-spindle BTA-STS Single-spindle Gundrill tool + BTA-STS tool MFTB 1000 /51 CR GDK MFTB 1500 /51 CR GDK MFTB 2000 /51 CR GDK Drilling diameter range min-max with gundrill tool 8 - 24 mm Drilling diameter range min-max with BTA-STS tool 18 - 51 mm Drilling depth (respectively) 1000/ 1500/ 2000 mm Workpiece counter-rotation 80 rpm Locking hydraulic Drilling spindle 22,0 kW - 3.500 rpm Oil pressure max. 50 / 80 bar ITALIAN TECHNOLOGY In the intermediate diameter range between the Gun Drilling and the BTA Drilling, we propose a Double-Setup flexible solution we called IMSA “GDK” System. This enables you to better take advantage of both tool types. Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max. Single-spindle BTA-STS Drilling diameter range min-max Drilling depth (respectively) Workpiece counter-rotation Locking Drilling spindle Oil pressure max.

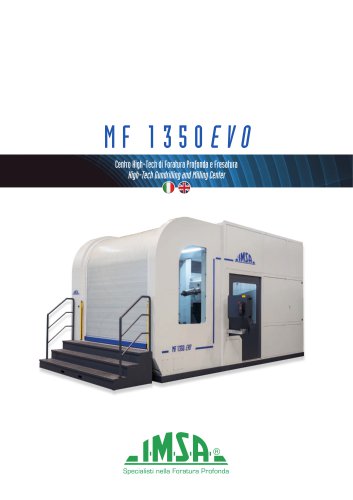

Open the catalog to page 1All IMSA srl catalogs and technical brochures

-

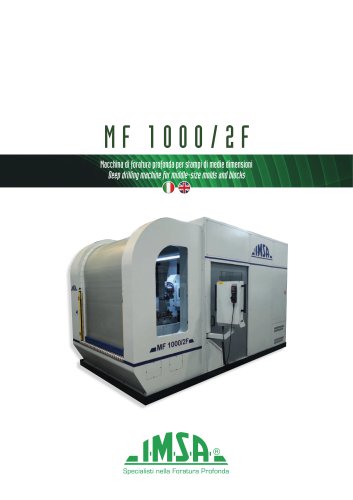

MF 1000/2F

9 Pages

-

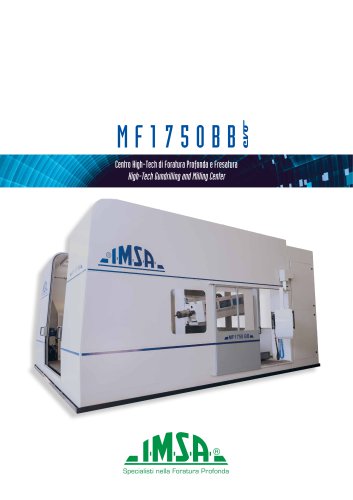

MF1750BB | 1750mm, Ø5-50mm

11 Pages