Website:

IMO GmbH & Co. KG.

Website:

IMO GmbH & Co. KG.

Group: IMO

Catalog excerpts

Special products for specialty vehicles Customer-specific IMO slew drives and slewing rings have proved their worth for years in fire-fighting and rescue deployment with their long service life and reliability. A single-row ball slewing ring with internal gear is being used in the turntable ladder shown below Special vehicles Fire department & rescue • • • • • • • turntable ladders elevated rescue platforms rescue crane / davits masts water cannons elevated launchers gangways / rescue bridges … single row and double row ball slewing rings 3-row roller slewing rings external gear, internal gear or without gear customer-specific designs Telescopic gangways for service an

Open the catalog to page 1

Your Advantages for purchasing • • • customer-specific solutions possible one unit instead of individual components low overall costs long service life extremely sturdy low maintenance costs modular system compact & space-saving reduces construction & installation costs closed housing, high level of working and operational safety ready for installation with an elegant shape runs smoothly without jerking IMO made in Gremsdorf, Germany More than 25 years on your side. Elevated rescue platform equipped with a WD-L slew drive pinion and worm driven versions closed housing for harsh...

Open the catalog to page 2

Ride on the safe side With it's proven customized solutions, IMO offers the highest safety standards with the best performance and functionality for amusement park rides of all kinds. WD-L slew drive for the seating area of a 3-D movie theater pinion and worm driven versions closed housing for highest level of safety max. torques up to 450 kNm max. breakaway torque load up to 1200 kNm raceway diameters up to approx. 1000 mm Rotary, swivel, and slewing tasks in one compact solution. Available in a broad palette of economical standard solutions or as a customized solution. amusement park...

Open the catalog to page 3

Your Advantages for purchasing • development with the spotlight on cost-efficient solutions delivery times you can rely on short reaction times reduced servicing costs longer service life worldwide service & spare parts advice from experienced engineers shock resistant and vibration-resistant mounting runs smoothly and without jerking calculation method regularly checked by certification organizations, e.g. TÜV highest degree of operational safety customized sturdy solutions maximum durability low overall costs IMO made in Gremsdorf, Germany More than 25 years on your side. Certifications •...

Open the catalog to page 4

Slew on the safe side IMO slew drives ensure the most efficient possible transmission of high power and torque inside a compact, closed unit. • easy motor assembly • fully encapsulated Forestry and Agriculture WD-L series: 8 sizes, torque from 3.2 to 42.8 kNm a fully enclosed unit self-contained component – no separate sub-components perfectly fitting parts fast installation protective housing screw it on, connect it up and you're ready to go An IMO WD-L series slew drive at work: smooth, jolt-free movement – no stick/slip effect unlimited slewing range maximum safety through full...

Open the catalog to page 5

Slewing Rings single and double-row ball slewing rings • • • long service life exceptional operating safety reduced costs over the product's lifetime Available in a wide range of standard sizes or as customized special solutions; optimized for the agricultural and forestry sector. IMO slewing rings and slew drives in action: The felling head and the swiveling driver cabin for the swivel arm's axle. IMO made in Gremsdorf, Germany These products are currently in use in wood choppers and in combination forestry vehicles: Slew Drives More than 25 years on your side. with integrated driving...

Open the catalog to page 6

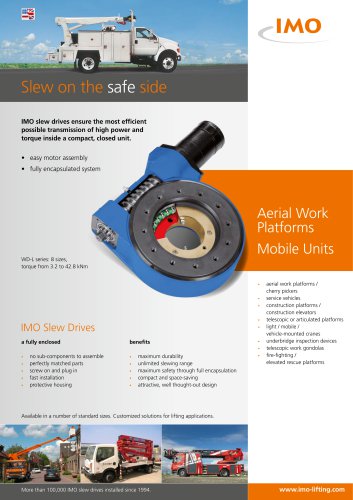

Slew on the safe side IMO slew drives ensure the most efficient possible transmission of high power and torque inside a compact, closed unit. • easy motor assembly • fully encapsulated system Aerial Work Platforms Mobile Units WD-L series: 8 sizes, torque from 3.2 to 42.8 kNm IMO Slew Drives a fully enclosed no sub-components to assemble perfectly matched parts screw on and plug in fast installation protective housing maximum durability unlimited slewing range maximum safety through full encapsulation compact and space-saving attractive, well thought-out design aerial work platforms / cherry...

Open the catalog to page 7

Your advantages for purchasing • • cost efficient all in a single unit (including slewing ring, motor, brake etc.) perfect, pre-adjusted components proven standard solutions low complexity low maintenance fully encapsulated and protected longer service life pre-configured and pre-lubed robust design a drop-in-solution fully pre-configured unit compact & space-saving developed by expert specialists application-specific advice no stick-/slip effect – smooth, jerk-free slewing maximum durability enclosed housing prevents dirt unlimited slewing range low maintenance costs integrated design IMO made...

Open the catalog to page 8

Slew on the safe side Customer-specific slewing rings by IMO have been impressing the crane industry for more than 25 years with their long service life and reliability. Slewing rings for cranes diameters over 6 m external gears, internal gears or without gears single row and double row ball slewing rings 3-row roller slewing rings gear rims customer-specific versions Mobile crane Harbor crane Handling crane Construction crane

Open the catalog to page 9

Your Advantages for purchasing • • • focus on cost-efficient solutions delivery times you can rely on short reaction times reduced servicing costs long service life worldwide service & spare parts customer-specific versions special seals to prevent ingress of dirt and coarse particles FE analysis of adjacent structure customized sturdy solutions high levels of operational safety highest level of resilience low overall costs IMO made in Gremsdorf, Germany More than 25 years on your side. A double row ball slewing ring is used in this loading crane The superstructure is rotated using a single...

Open the catalog to page 10All IMO GmbH & Co. KG. catalogs and technical brochures

-

Bottling Industry

2 Pages

-

Funrides

2 Pages

-

IMO Slew Drives for Steering

2 Pages

-

Offshore Cranes

2 Pages

-

IMO Slew Drives for Lifting

2 Pages

-

Public Transportation

2 Pages