Website:

IMMA Global A.S

Website:

IMMA Global A.S

Group: IMMA Global Group

Catalog excerpts

^ IMMAGLOBAL IMMA's mining, crushing and screening solutions assures the latest technology in terms of material, casting, equipment , after-sales, components with the most competitive pricing from a customer-based engineering company. IMMA comes up with cooperations supplied by in-house and global reputable manufacturers. That enables IMMA's project: A wide range of solutions for the projects Solutions for aggregates, ores, enrichment, fine screening Reliable and sustainable quality above standards Best Return-Of-Investment Minimized running cost Worldwide spare part and maintenance...

Open the catalog to page 2

State of Art “Crushers” Jaw Crusher / IMC Series Up to 1200 tph | 450mm to 1200 mm Cone Crusher / MCH Series Up to 780 tph | 10mm to 350mm Hydraulic Impact Crusher / INP Series Up to 1000 tph | Up 1200mm Vertical Shaft Impact Crusher / IVS Series Up to 750 tph | 45mm to 80mm Double Roll Crusher Up to 3.000 tp

Open the catalog to page 3

Mineral Process & Enrichment Best in the class for process and enrichment solutions Highest efficiency and productivity Enrichment process from 1mm to 45 micron Unique solutions for: Construction Chemicals Moist Clay Emery and Silica Sand Perlite Limestone Gypsum Olivine Zeolite Magnesite Bentonite Pomice

Open the catalog to page 4

Jaw Crushers IMC Series CAPACITY : 70-1.200 tph FEEDING SIZE : Up to 1200 mm Optimized crushing chamber, feed and crushing efficiency! Energy saving up to 30% Strong bearings for long life endurance Stable and solid eccentric shaft forging & billet processing Mn22% casting and plates Centralized lubrication, Gasket type discharge adjustment Low noise & less dust and Easy Maintenance Rack diversification by welded heavy frame or modular removable frame, Integrated motor base design, occupying smaller area Deep-V Cavity design to increase, crushing efficiency by moment of inertia and Crushing...

Open the catalog to page 5

1 feed hopper 2 fixed jaw plate 3 installation leg 4 toggle plate 5 discharge open adjusting device G pull rod 7 safety guard 8 V belt 9 motor 10 flying pulley 11 frame 12 tension block 13 bolts for lining plate 14 top side lining plate 15 below side lining plate 16 safety guard Eccentric Shaft Speed (rpm)

Open the catalog to page 6

Cone Crushers MCH Series CAPACITY : 70-1.200 tph FEEDING SIZE : Up to 1200x1600 mm Large crushing ratio, High production efficiency: High eccentricity, large crushing ratio, fast speed, up to 750 RPM Improved production capacity by 30%~40%; Hydraulic protection and hydraulic cavity cleaning, High automation, Reduced downtime; Integrated hydraulic lubrication, thin oil lubrication system design, the use of U\T labyrinth seal and positive pressure fan to ensure reliable dust; To achieve flexible cavity type switching through replacing liner, cutting ring, fastening bolts; Reasonable...

Open the catalog to page 7

Cone Crushers MCH Series 1 upper frame 2 lower frame 3 cone part 4 driving part 5 hydraulic cylinder 6 feeding hopper 7 eccentric bushing 8 sealing device Model Cavity Type Motor Power Capacity at CSS (Close Side Setting) (t/h) 13mm 16mm 19mm SC: Standard Course, EC: Extra Course, SM: Standard Medium, MF: Medium Fine, SF: Standard Fine

Open the catalog to page 8

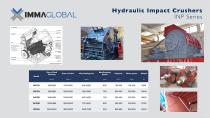

Hydraulic I mpact Crushers INP Series ► CAPACITY: 100-2.000 tph . FEEDING SIZE: Up to 1.500 mm ► Coarse, medium and fine crushing with large crushing ratio and good grain shape of finished products. ► Optimize heavy-duty rotor design, increased rotational inertia and improved productivity ► Unique locking device of wedge plate hammer to obtain a convenient disassemble, safe and reliability Flexible configuration for entire models by two or three cavities, cavity type and wear-resistant plate hammers Hydraulic design equipped to open the frame and adjust discharging port conveniently;...

Open the catalog to page 9

Hydraulic Impact Crushers INP Series Model Size of Feed Opening (mm) Rotor size D*L Max feeding size (mm) Capacity Motor power Weight (t/h) (kw) INP1110 1020x820

Open the catalog to page 10

Vertical Shaft Impact CrushersIVS Series CAPACITY : 70-955t/h MAX FEEDING SIZE : 30-60mm PROCESS: Aggregate, iron ore, copper ore, cement, artificial sand, fluorite, limestone, slag, etc. Vertical shaft impact crusher / sand maker Highest efficiency for sand making & ore processing High-quality finished product crushing Multi-purpose usage in one machine Multi-stage crushing to optimize product quality High safety protection level Convenient maintenance Easy installation

Open the catalog to page 11

IMMAGLOBAL Vertical Shaft Impact Crushers IVS Series 1 lift device 2 sling tray 3 crushing cavity 4 pedal brocket 5 motor 6 motor seat 7 V belt pulley 8 bearing cylinder 9 bracket 10 frame 11 rotor 12 feed hopper

Open the catalog to page 12

CAPACITY: 60-255 tph MAX FEEDING SIZE: 25mm Key element to obtain milling after crushing. Strong adaptability to materials, continuous production, Large capacity and crushing ratio (Up to 300), Easy to adjust the fineness of the grinding product; Suitable for dry and wet operation; Simple structure, solid, reliable operation, simple maintenance and management, high operating rate; Strong sealing, can be negative pressure operation. Ball Mills BM Series

Open the catalog to page 13

Ball Mills IBM Series Model Loading Feeding Size Discharge Capacity Capacity (t) (mm) Size (mm) (tph) 1 cylindrical shell 2 lining plate 3 inlet 4 feed screw 5 bearing cover 6 bearing seat 7 roller 8 rack 9 plate 10 driving seat 11 overbridge bearing seat 12 small gear 13 speed reductor 14 shaft coupling 15 motor 16 big gear 17 lining plate

Open the catalog to page 14

Vibrating Screens TE Series Designed to have a wide range of applications with high capacities Industrial protected vibromotor, Steel spring wire, Labyrinth tapped SS 4140 screen gears, Welded solid structure Constant chassis and solid structure Reliable spare parts and tools, Long-lived and minimized operation cost, Standard Models: Model 2TE1640: 1600 mm x 4000 mm with 2 decks Model 4TE2060: 2000 mm x 6000 mm with 4 decks Model 3TE1650: 1600 mm x 5000 mm with 3 decks Model 3TE2460: 2400 mm x 6000 mm with 3 decks Model 3TE2050: 2000 mm x 5000 mm with 3 decks Model 4TE2460: 2400 mm x 6000...

Open the catalog to page 15

^ IMMAGLOBAL ► CAPACITY: Up to 850 tph * Economical cost-effective along with high efficiency ► Developed by Japanese technology ► Simple, basic and compact structure * Smooth operation without vibration, good mute effect; ► Large processing capacity, strong sorting ability, small installation inclination, * Unplugged screen with accurate particle size sorting; . Simple mesh replacing ► Equipped with bag-breaking props for solid waste screening with no winding. Trommel GTS Series Model Drum Diameter Speed Capacity Power

Open the catalog to page 16All IMMA Global A.S catalogs and technical brochures

-

IMMA Fine - Micronized Screens

10 Pages

-

Certificates

5 Pages

-

IMMA Cryogenic Tanks & Stations

15 Pages

-

IMMA Tanker Semi-Trailers

2 Pages

-

Silo Semi-Trailer

2 Pages

-

Tank Remourque / Trailers

3 Pages

-

Flatbed Semi-Trailers

3 Pages

-

Concrete Batching Plant

15 Pages

-

Concrete Pump Boom Trailer

3 Pages

-

IMMA Over-head Cranes

8 Pages

-

IMMA Steel Works

14 Pages

-

CRUSHING & SCREENING

10 Pages

-

CONCRETE BATCHING & PROCESSING

11 Pages

Archived catalogs

-

PUMP TRAILER "ALTER" Sériés

2 Pages