Website:

IMKO Micromodultechnik

Website:

IMKO Micromodultechnik

Catalog excerpts

ATEX-Products ATEX Guideline 2014/34/EU| The right moisture sensor for every application Moisture Sensor Experts II 2 D Ex tb IIIC T75°C Db conformable EPS 20 ATEX 1 237 X

Open the catalog to page 1

X Founded in 1984 as an engineering company, IMKO GmbH has been working on moisture measurement for over 30 years now. X Based on the unique TRIME-TDR technology, IMKO experts developed sensors for science and meteorology in the early 90s. A few years later, the product range was extended with solutions for measuring moisture in grain, primarily for applications in the agricultural sector. X Si nce the introduction of the SONO series in 2010, IMKO GmbH now offers a product portfolio that enables moisture measurement in any material, even for detection of just a few drops of water in solids,...

Open the catalog to page 2

IMKO – Application fields Bulk solids

Open the catalog to page 3

The IMKO TRIME-TDR measurement method The sensors developed by IMKO are based on measurement with Time Domain Reflectometry, or TDR for short. In principle, this measurement method is suitable for a range of applications, such as cable break detection or even measurement of fill levels. When applied specifically for measuring moisture in bulk solids and liquids, the physical effect is used, which correlates the propagation speed of electromagnetic waves with the dielectric properties of the material to be measured. Since water has a significantly higher dielectric constant than the...

Open the catalog to page 4

TDR measurement with the patented TRIME method Implementing a TDR measurement is usually associated with significant technical effort. Very accurate pulses must be generated and the measurement requires the utmost in precision. Therefore, for a long time, TDR technology remained a laboratory measurement method kept back for science. Measuring devices based on TDR were not only very expensive, but also large and unsuitable for field use. The TDR technology optimized by IMKO specifically for material moisture measurement, the TRIME method (Time Domain Reflectometry with Intelligent...

Open the catalog to page 5

The SONO probe as a "moisture tomograph” The guided radar wave (in green) propagates at approximately the speed of light. The sensor measures the material layer by layer discoidally and transverse to the sensor surface, as is familiar from a computer tomograph, for example. This method results in a sensor with an exactly defined measurement field, which can measure without errors even in the event of fluctuating fines or varying grain size. By measuring transverse to the sensor surface, the mechanical condition of the sensor surface does not represent a disturbance variable, i.e. the...

Open the catalog to page 6

SONO process moisture probes for the bulk solids industry Increase your plant safety and save time and resources through innovative sensor technologies All foodstuffs and bulk solids contain a proportion of water. The moisture content not only determines the quality of products, but also their shelf life and due to the weight, their price. Legal requirements lay down the framework. With material moisture measurement, you can determine the water content in your foodstuffs and bulk solids. IMKO is presenting a new generation of moisture probes in the form of its SONO probes. These were...

Open the catalog to page 7

Predictive sensor networking through intelligent device communication SONO-Ex Probes enable easy and user-friendly sensor networking Standard RS485 interfaces often pose significant challenges. They are not galvanically isolated and there is always the risk of ground loops or interference pulses, which can result in significant safety problems. For long cable lengths in particular, a shielded and twisted cable must be used. Depending on the wiring plan (topology), a 100 Ohm terminating resistor must be installed at sensitive locations in the RS485 network when there are individual spurs. In...

Open the catalog to page 9

Application field for SONO-Ex MIX Mini probes SONO-Ex MIX Mini series enables: x Direct moisture measurement in the material, even at hard-to-reach areas of your process x Continuous recording and monitoring of moisture content and temperature x Improved and more accurate process control during all steps x Improved process stability and thus lower product losses (over-drying: structural loss; under-drying: moulding) x Cost savings by improved energy efficiency (due to less overdrying) The SONO-Ex MIX Mini HC is the ideal humidity probe for determination of material moisture in more compact...

Open the catalog to page 10

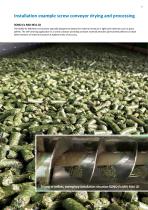

Installation example screw conveyor drying and processing SONO-Ex MIX Mini LD The SONO-Ex MIX Mini LD has been specially designed to detect the material moisture in light bulk materials such as grasspellets. The self-cleaning application in a screw conveyor providing constant material densities permanently delivers an ideal determination of material moisture at highest levels of accuracy. Drying of pellets, exemplary installation situation SONO-Ex MIX Mini LD

Open the catalog to page 11

Installation example in sawdust and wood chips/wood pellets, powders, flours, dusts Using SONO-Ex GS1 enables: x Direct moisture measurement in the material, even at hard-to-reach places x Continuous recording and monitoring of moisture content and temperature x Improved and more accurate process control during all work processes x Increased process stability and thus lower scrap rates x Cost savings due to increased energy efficiency (due to less over-drying) Drying bulk solids in belt dryers When drying bulk solids with belt dryers, an air-permeable belt is filled with the product to be...

Open the catalog to page 12

Installation example screw conveyor in goods with a particularly low density The SONO-Ex GS1 with its particularly large measuring field was specially designed to detect the material moisture of bulk materials with very low density. The self-cleaning application under constant material densities permanently ensures an optimal determination of highly accurate measuring values. Also the measurement of flours, dusts and pigments is an ideal application field for the SONO-Ex GS1. If the SONO-Ex GS1 probe is installed along the screw conveyor on the discharge, an installation angle of 30° is...

Open the catalog to page 13All IMKO Micromodultechnik catalogs and technical brochures

-

SONO-WZ

4 Pages

-

SONO VARIO

4 Pages

-

SONO MIX

4 Pages

-

Flyer SONO WZ_EN

2 Pages

-

IMKO BULK SOLIDS BROCHURE

16 Pages

-

IMKO CONSTRUCTION BROCHURE

20 Pages

-

IMKO SOIL BROCHURE

28 Pages

Archived catalogs

-

SONO MIX MINI LD EN

2 Pages

-

SONO VARIO LD EN

2 Pages

-

SONO VARIO XTREM

2 Pages

-

SONO-MIX MIXER PROBE

7 Pages

-

SONO-MIX MINI

2 Pages

-

PICO-PROFILE T3PN

4 Pages

-

SONO-MIX

8 Pages