Catalog excerpts

Critical Engineering

Open the catalog to page 1

Company ‣ Established 1960 in Gorle, Bergamo (Italy) ‣ Acquired by IMI 2002, part of IMI Critical Engineering ‣ Opened a Quarter Turn division near Piacenza (Italy) ‣ Since 2014 located in Levate, Bergamo (Italy) ‣ Several International Patents, Certifications & Approvals ‣ Key Markets are Oil & Gas and Power ‣ Development, Design and Production of Pneumatic Actuation Control Systems for Severe Services ‣ Over 90% of compressor antisurge valves in LNG WW are fitted with STI actuation cont

Open the catalog to page 2

Company ‣ Area 15,000 m²: 12.000 m² workshop & 3.000 m² offices ‣ More than 115 employee

Open the catalog to page 3

What we do… “An actuator is a type of motor for moving or controlling a mechanism or system. It is operated by a source of energy, usually in the form of an electric current, hydraulic fluid pressure or pneumatic pressure, and converts that energy into some kind of motion.” STI core business is development, design and manufacture of pneumatic actuators to operate modulating equipments such as valves, dampers, fans inlet drives and other devices. We focused on demanding applications in terms of forces, speed, accuracy, or a combination of them. This requires not just the “muscle” (the...

Open the catalog to page 4

ftRE^T Solutions \ Critical Engineering Energia Cost* Azul Sinfeib Patronaa Floating LNG-1 Shin Minato Peoyang Tae< Qorgon LNQ North Weet Escobar Gaaport

Open the catalog to page 5

complete pneumatic control systems for critical Critical Engineering special equipments

Open the catalog to page 6

following customer's and project's market and in major Vendor's List with ftRE^T Solutions \ Critical Engineering A SutoMtary of Kimtt PBMMOTI Corporation VENDORS & CONTRACTOR This document certifies that the manufacturing facility of have been assessed and approved to supply of the following producl(s) for KNPC Product Description 16 45 VALVE ACTUATORS PNEUMATIC PLEASE REFER OVERLEAF FOR INSTRUCTIONS TO THE VENDOR

Open the catalog to page 7

Critical Engineering

Open the catalog to page 8

Applications UP / Midstream O&G ‣ Compressor anti-surge ‣ Hot gas bypass ‣ Choke valves ‣ Gas to flare ‣ Dampers for fans ‣ Louvers POWER ‣ Turbine bypass systems ‣ Steam damper heating ‣ Boiler level control (inc. Nuclear) ‣ Pump recirculation ‣ Emergency shut down ‣ Line isolation ‣ Dam

Open the catalog to page 9

Competitor’s actuator Competitor actuator called “PUZZLE” Various Accessories Various different companies Positioner: Company A Linkage: poor without engineering (Company B) Air-lock: not integrated dangerous execution (Company C) Cylinder: Company

Open the catalog to page 10

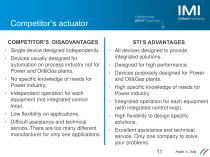

Competitor’s actuator COMPETITOR’S DISADVANTAGES ‣ Single device designed independently. ‣ Devices usually designed for automation on process industry not for Power and Oil&Gas plants. ‣ No specific knowledge of needs for Power industry. ‣ Independent operation for each equipment (not integrated control loop). ‣ Low flexibility on applications. ‣ Difficult assistance and technical service. There are too many different manufacturer for only one applications. STI’S ADVANTAGES All devices designed to provide integrated solutions. Designed for high performance. Devices purposely designed for...

Open the catalog to page 11

Control drive Quarter turn V – large enclosed actuator L – enclosed actuator APL – lever actuator Q – high torque actuator – damper actuator BD – derivative booster BV – big volume booster BW – ultra high capacity booster CO – 3-way valve GR – manual override MC – motion converte

Open the catalog to page 12

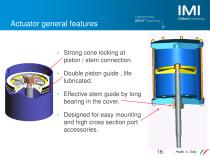

Actuator general features ‣ Double piston guide system, patented life self lubricated. ‣ Strong cone locking at piston / stem connection. ‣ Lower bearing guide system and effective stem guide by long bearing in the cover for spring actuator. ‣ Specific safety spring design. ‣ Most of actuators have manifold mounting connection

Open the catalog to page 13

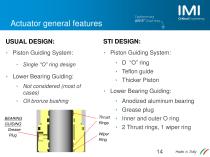

Actuator general features USUAL DESIGN: ‣ Piston Guiding System: ‣ Piston Guiding System: ‣ D “O” ring ‣ Single “O” ring design ‣ Teflon guide ‣ Lower Bearing Guiding: ‣ Not considered (most of ‣ Thicker Piston ‣ Lower Bearing Guiding: ‣ Anodized aluminum bearing ‣ Grease plug BEARING GUIDING Grease Plug Thrust Rings ‣ Inner and outer O ring ‣ 2 Thrust ri

Open the catalog to page 14

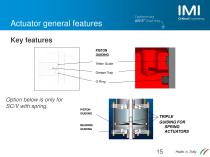

Actuator general features Key features PISTON GUIDING Teflon Guide Grease Trap O-Ring Option below is only for SC/V with spring. PISTON GUIDING BEARING GUIDING TRIPLE GUIDING FOR SPRING ACTUATORS

Open the catalog to page 15

Actuator general features ‣ Strong cone locking at piston / stem connection. ‣ Double piston guide , life lubricated. ‣ Effective stem guide by long bearing in the cover. ‣ Designed for easy mounting and high cross section port accessories

Open the catalog to page 16

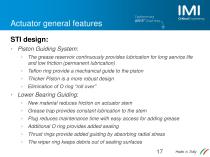

Actuator general features STI design: ‣ Piston Guiding System: ‣ The grease reservoir continuously provides lubrication for long service life and low friction (permanent lubrication) Teflon ring provide a mechanical guide to the piston Thicker Piston is a more robust design Elimination of O ring “roll over” ‣ Lower Bearing Guiding: ‣ New material reduces friction on actuator stem Grease trap provides constant lubrication to the stem Plug reduces maintenance time with easy access for adding grease Additional O ring provides added sealing Thrust rings provide added guiding by absorbing radial...

Open the catalog to page 17

Actuator general features ‣ No spring torque by means of bearing. Triple guide for less radial stress. Safety disassembling system. Strong cone locking at piston / stem connection. Double piston guide , life lubricated. Designed for easy mounting and high cross section port accesso

Open the catalog to page 18

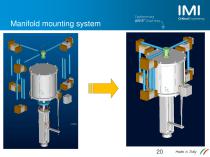

Actuator general features MANIFOLD MOUNTING SYSTEM: A plug-in system is used to apply the accessories in order to: ‣ maximize the port size connection (Max CV); reduce the actuator overall dimension; have an easy and fast mounting; reduce the use of hoses and fittings; minimize vibration effe

Open the catalog to page 19

Manifold mounting system

Open the catalog to page 20

Linear actuator – SC Series SC – Damper actuator ‣ Designed to meet SIL3 requirements as a “single device” ‣ ATEX 94/9/EC and PED 97/23/EC compliance ‣ Operating pressure: max 1.000 kPa ‣ Standard operating temperature: -20°C to +70°C ‣ Thrust: up to 850.000 N SCV – Valve actuator ‣ Designed to meet SIL3 requirements as a “single device” ‣ ATEX 94/9/EC and PED 97/23/EC compliance ‣ GOST certification ‣ Operating pressure: pneumatic version up to 10 barg ‣ Standard operating temperature: -20°C to 70

Open the catalog to page 21All IMI STI catalogs and technical brochures

-

Stepper Motor Actuators SM

4 Pages

-

Air quality

5 Pages

-

Brochure RTC

4 Pages

-

Brochure_CS

2 Pages

-

Brochure_AL

2 Pages

-

Company_profile

10 Pages

-

Brochure accessories

40 Pages

Archived catalogs

-

231 guidelines_STI_30-9-2015

8 Pages