Catalog excerpts

The CORiTEC 150i series WHAT ARE THE DIFFERENCES? CORiTEC 150i PRO PC Touchscreen Integrated PC Premilled Abutments Dry processing Metal processing* Integrated water tank Ionizer Auto calibration Automated cleaning function Chip tray *limited metal processing (blank) in preparation

Open the catalog to page 2

Features Minimum compressed air requirement WHETHER WET OR DRY MACHINING, BLOCK OR BLANK FORM, THE CORiTEC 150i SERIES IMPRESSES IN ALL AREAS. UNLIMITED FLEXIBILITY IN MILLING AND GRINDING – THAT'S THE PROMISE OF THE CORiTEC 150i SERIES Each restoration is fabricated with optimum precision and, at the same time, the flexibility opens up an almost free choice of materials and indications. Milling and grinding of zirconium, plastics and metal** is possible, as is the machining of CAD/CAM blocks and Pre-milled abutments. The CORiTEC 150i offers an unrivalled variety of applications in a very...

Open the catalog to page 3

MORE PERFORMANCE, MAXIMUM FLEXIBILITY AND EXTENDED APPLICATION POSSIBILITIES WITH MINIMAL SPACE REQUIREMENTS An exceptional ratio of power, speed and precision – this is what the powerful high-frequency spindle with 750 W and 100.000 rpm offers. Thanks to the quick-clamping system, the various holder systems can be changed quickly and easily – while maintaining the same precision. Time-consuming calibrations are therefore unnecessary. A VARIETY OF HOLDING SYSTEMS OFFERS MAXIMUM FLEXIBILITY FOR MAXIMUM CHALLENGES Also new is the support of the half-open blank holder, the so-called "C-Clamp"....

Open the catalog to page 4

CORiTEC 150i PRO THE FLEXIBLE MILLING SYSTEM IN CONFINED SPACES The extremely stable design of the mono-block cast body enables precise machining with round blanks and block forms. The machine‘s small dimensions and 5-axis simultaneous technology offers a unique ratio of machine size and functionality. Convince yourself of the performance of the CORiTEC 150i for your laboratory!

Open the catalog to page 5

ERGONOMIC HANDLING simple graphical touchscreen operation EASY CLEANING fully coated enclosed wet cell POWERFUL PERFORMANCE high end spindle for milling and grinding work up to 100.000 rpm HALF-OPEN BLANK HOLDER "C-CLAMP" (OPTIONAL) INTEGRATED WATER TANK AND FILTRATION INTEGRATED TEMPERATURE COMPENSATION Novel, closed mono-block cast body for highest stability and precision No external PC required Half-open blank holder "C-Clamp" (optional) Ionizer inclusive High precision due to integrated temperature compensation Wet and dry machining possible Minimum external compressed air, only 3 bar...

Open the catalog to page 6

T5/ T10/ T17 - 1.5 I 3.0 mm shaft milling tool (l = 15 mm), universal T11 - 2.5 I 3.0 mm radius milling tool (single blade, slide coated) up to 25 mm PMMA WAX Zr SINT COMP T98 - 2.5 I 3.0 mm shaft milling tool (l = 20 mm, three blades) PMMA WAX Zr SINT COMP T23 - 0.6 I 3.0 mm radius grinding tool (conical, diamond) T22 - 1.0 I 3.0 mm radius grinding tool (diamond) T15/ T42/ T52 - 0.6 I 3.0 mm radius milling tool (conical) T14/ T41/ T51 - 1.0 I 3.0 mm radius milling tool (diamond coated) T21 - 2.5 I 3.0 mm radius grinding tool (diamond) T33/ T43/ T53 - 0.3 I 3.0 mm radius milling tool...

Open the catalog to page 7

CORiTEC Materials CORiTEC ZR (ZIRCONIUM DIOXIDE) JUVORA PEEK (POLYETHERETHERKETONE) Covers all indications for dental restorations of up to 16 units. Ideally suited for monolithic restorations. • Clamp-retained constructions • Juvora PEEK in its basic colour (brown-beige) • Highest biological compatibility • Highly translucent zirconium dioxide for natural esthetics • Increased strength compared to lithium dioxide Zr ht+ Disc (highly translucent) Zr transpa Disc (pre-colored translucent) CORiTEC WAX DISC (WAX, GRAY) CORiTEC Wax Disc is not suitable for intraoral application. After milling,...

Open the catalog to page 8

CORiTEC SmartControl™ SMART CONTROL OF MACHINE SOFTWARE SmartControl™ one touch ahead! The newly developed control software „SmartControl™“ provides absolutely intuitive operation of our milling machines. From selecting the job to milling or querying the machine status; the self-explanatory and optimized handling makes it possible to start operating the machine in the shortest possible time. Starting a milling process requires only two clicks – benefit from the smart time savings for your workflow! Optimized for touchscreen operation Modern touch control design Easiest operation through...

Open the catalog to page 9

Full integrated workflow OPEN TO ALL COMMON SCANNERS Applications & holders HALF-OPEN BLANK HOLDER (C-CLAMP) • Enables 5-axis machining up to 90 degrees axis adjustment • Extension of the technical possibilities of your milling machine UNIVERSAL HOLDER FOR TURN-MILL-GRINDING PROCESSING scanner • High precision • Improved surface quality • Tool-saving machining PREFABRICATED ABUTMENTS Short production times Production of abutments in very simple processes High accuracy of fit due to prefabricated implant interface DESS Abutmentholder NT-Preform® Abutment (nt-trading) PreFace® Abutment...

Open the catalog to page 10

Sintering furnaces Suction system iVAC silent & iVAC silent PRO The iSINT eco stands for economy and offers high-quality technology, matching accessories for high standards at a fair price. Compact and with a small footprint, the iSINT eco sintering oven still has sufficient capacity for a sintering bowl Ø100 mm for approx. 25 units. The door stop can be mounted at the right or left side. The system is equipped with a teflon filter catridge, automatic filter cleaning and a dust drawer. With the suction power of 160m³/h the iVAC silent is perfectly suited for your CORiTEC 150i and is even...

Open the catalog to page 11

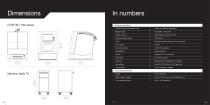

Mechanics / electronics Hilling and grinding tools with 3 mm tool shaft Tool changer Tool length control Windows based SmartControl™ integrated CNC software Cooling liquid Maximum spindle speed Spindle / power 5 axes, simultaneous processing Rotation angle Number of axes and operation type Connecting requirements Line voltage / frequency Width x depth x height 90 cm 35.4 inch

Open the catalog to page 12

Sales and support partner worldwide Represented for you in over 100 countries. imes-icore® GmbH has been a leading manufacturer and technology partner since 2003 in the field of dental CAD/CAM systems and solutions. With its unique range of dental milling and grinding systems, imes-icore® offers a perfect selection for all individual requirements of dental laboratories, milling centres and dental practices of all sizes. Our “Open-System” product philosophy makes it possible to easily integrate our milling machines into your existing workflow and to integrate them with your open scanners and...

Open the catalog to page 13All Imes-icore GmbH catalogs and technical brochures

-

isyCAM 2.8

1 Pages

-

vacuum clamping systems

2 Pages

-

PLATINUM X5

2 Pages

-

i-las Engraving Module

2 Pages

-

Milling Automation

2 Pages

-

WIN-Remote

1 Pages

-

Point laser sensor CONOPROBE

2 Pages

-

CNC water jet cutting

4 Pages

-

Platinum 1000

2 Pages

-

PREMIUM 4030 µ graphite

8 Pages

-

Premium 3020

2 Pages

-

FLATCOM series

2 Pages

-

EUROMOD series

2 Pages

-

ICV 4030

2 Pages

-

ICP-Series 3020/4030

2 Pages

-

SFY/ SPY series

2 Pages

-

GPY series

4 Pages

-

GFV / GFY series

2 Pages

-

catalogue 2012

187 Pages