Website:

Imao Corporation

Website:

Imao Corporation

Catalog excerpts

Value Creator Quick Shaft Clamps

Open the catalog to page 1

ONE-TOUCH SPINDLE LOCKS QUICK SHAFT-LOCKING CLAMPS QUICK SHAFT-LOCKING CLAMPS (Pneumatic) PNEUMATIC SHAFT LOCKING CLAMPS PNEUMATIC SHAFT LOCKING CLAMPS SENSOR BRACKETS

Open the catalog to page 2

Value Creator

Open the catalog to page 3

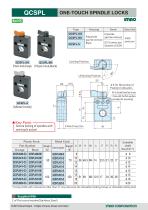

QCSPL ONE-TOUCH SPINDLE LOCKS QCSPL-S (Metal knob) 8 (Width of Clamp Collar) ★Key Point Secure locking of spindles with one-touch action! Supplied With 2 of Flat round washer(Stainless Steel)

Open the catalog to page 4

Feature ・One-touch Spindle Locks enable quick and secure locking of shafts with one click of the knob. ・When One-touch Spindle Lock is operated, the knob clicks and the shaft is locked with a steady force. This provides reliable locking of shafts. ・The knob position and the indication line clearly indicate lock/unlock position. ■Conventional Method ■One-Touch Spindle Locks Just turn the knob. The indication line aligns when One-touch Spindle Lock is locked. For locking of sliding shaft Can be used with Position Indicator Suitable position indicators Note: To mount position indicators to...

Open the catalog to page 5

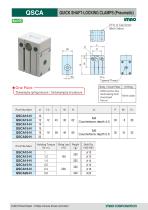

QUICK SHAFT-LOCKING CLAMPS Body / Handle Part Number Part Number

Open the catalog to page 6

Supplied With Four hex. socket setscrews ■As the handle is turned down, it pushes the locking block toward the shaft for clamping. When the handle is released, the flat spring allows the locking block to be returned to the original position. ■Both faces can be used for installation. Two sides with two tapped holes can also be used for installation(remove the setscrews). Do not give hammer taps to the handle or extend the handle with a pipe or the like for easier clamping, to avoid any damage. Dimensions between the shaft-hole center and the sides are not precise. When installing a Quick...

Open the catalog to page 7

QUICK SHAFT-LOCKING CLAMPS (Pneumatic) 2-For di Cap Screw (Both Sides) Body / Cover Plate ★One Point Clamping by spring pressure / Undamping by air pressure

Open the catalog to page 8

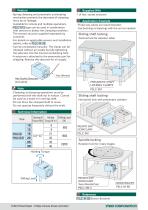

■How to Install Shaft Mounting Holes Air Threaded Plug Slide the clamp over the shaft at the Screwing the plug completely unclamped mode, and then fix the into the hole allows locking body using the 2 mounting holes. the shaft. Supplying air allows compressing the spring to get the shaft unlocked. Feature ・Air pressure to be applied : 0.5 - 0.7MPa Recommended to use with a three-way valve. ・The mechanism of spring-pressure clamping and air-pressure unclamping prevents shaft-locking force from getting lowered. ・Connecting air plumbing to multiple Quick Shaft-Locking Clamps installed allows...

Open the catalog to page 9

PNEUMATIC SHAFT LOCKING CLAMPS ★ Key Point - For automation of shaft locking. Low pressure type also available. Body, Clamp Shaft

Open the catalog to page 10

Application Example ■Spring clamping and pneumatic unclamping mechanism prevents the decrease of clamping force by air leakage. ■Available for remote and multiple operations. ■Perfect for use in limited space. ■IPSLC-3L1 type can be used with 0.3 MPa air pressure. ■Clamping/unclamping operations must be performed with the shaft not in motion. Cannot be used as a brake of a moving shaft. ■Do not force the clamped shaft to move. ■Do not operate frequently without the shaft. ■Manual unclamping is not possible. ■The 03 identification mark is used to distinguish IPSLC-3L I from I PSLC-5LI....

Open the catalog to page 11

PNEUMATIC SHAFT LOCKING CLAMPS (Standard, Single Acting) (Sensor Mountable, Single Acting) ★Key Point For automation of shaft locking. Usable with sensors. For 2-M Hex-Socket Head Cap Screw 2-M3×0.5 Mounting Hole for Sensor Brackets Clamping Shaft A5052 aluminum A5056 aluminum S45C steel Anodized Anodized Electroless nickel plated (Standard, Single Acting) Slots for Magnetic Sensors (Sensor Mountable, Single Acting) Pneumatic Port *) (For Manual Release) *) Delivered with the setscrew installed. See the Feature section for details. Part Number Standard Type Sensor Mountable Type Weight...

Open the catalog to page 12

Supplied With ■Spring clamping and pneumatic unclamping mechanism prevents the decrease of clamping force by air leakage. ■Available for remote and multiple operations. ■PSLC-M-Sl type can be used in combination with sensors to detect the clamping condition. The sensors must be supplied separately by customer. ■ For details on applicable sensors and installation details, refer to |PSLC-M-S~Bl ■Can be undamped manually. The clamp can be released without air supply by fully tightening the setscrew into the manual unclamping hole. ■A setscrew is attached to the pneumatic port for shipping....

Open the catalog to page 13

Stainless Steel . SENSOR BRACKETS Body SUS304 stainless steel Part Number *) Magnetic Proximity Sensors manufactured by ASA ELECTRONICS INDUSTRY CO., LTD. L-shaped sensors cannot be used with these brackets. Please refer to their catalog for details of sensors. Supplied With ■Clamping conditions can be detected by using applicable sensors. ■Sensor must be supplied separately by the customer. 2 of M3x0.5-5L Hex socket button head screw PSLC-M-S I PNEUMATIC SHAFT LOCKING CLAMPS (Sensor Mountable) ■ Remove the screws from the sensor cases with a slotted screwdriver and fix the sensors to...

Open the catalog to page 14

imflOCORPORATIOn www.imao.com /en 2002 Senbiki, Seki, Gifu 501-3954, Japan Tel : +81 575 28 5823

Open the catalog to page 15All Imao Corporation catalogs and technical brochures

-

Modular Pull Clamping System

35 Pages

-

MECHANICAL LINEAR ACTUATORS

49 Pages

-

PNEUMATIC CLAMPS

36 Pages

-

ONE-TOUCH SLIDING LOCKS

28 Pages

-

Spring Clamps

23 Pages

-

NUTRUNNER CLAMPS

24 Pages

-

ONE-TOUCH SLIDING LOCKS

35 Pages

-

5-Axis Clamping Systems

15 Pages

-

Machinable Collet Clamps

38 Pages

-

Side Clamps

27 Pages

-

Torque Limiting Knobs & Handles

16 Pages

-

Flex Locators

38 Pages

-

ONE-TOUCH CLAMPS

54 Pages

-

WORK SUPPORTS

24 Pages

-

PNEUMATIC CLAMPING FASTENERS

26 Pages

-

Bearing Guide Rollers

35 Pages

-

TENSIONERS

40 Pages

-

CLAMPS

106 Pages

-

HANDWHEELS & HANDLES

29 Pages

-

SCREWS & NUTS

13 Pages

-

CLAMPING KNOBS

23 Pages

-

LOCATING PARTS

14 Pages

-

GRIPPERS

19 Pages