Catalog excerpts

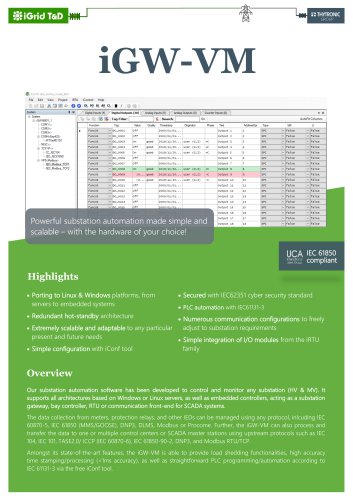

iGW-VM iRTU iControl Help D1 Dn fll Ana 1/ | < / Digital Inputs [4) )"’ Digital Outputs [30) [ Analog Inputs (0) | Analog Outputs (□) \y' Counter Inputs (0) | Quality Timestamp AddressOpr Type AutoFit Columns » iConf<test_online_mode_BO> File Edit View Project □ L " U Highlights • Secured with IEC62351 cyber security standard • PLC automation with IEC61131-3 • Numerous communication configurations to freely adjust to substation requirements • Simple integration of I/O modules from the iRTU family Overview Our substation automation software has been developed to control and monitor any substation (HV & MV). It supports all architectures based on Windows or Linux servers, as well as embedded controllers, acting as a substation gateway, bay controller, RTU or communication front-end for SCADA systems. The data collection from meters, protection relays, and other IEDs can be managed using any protocol, inlcuding IEC 60870-5, IEC 61850 (MMS/GOOSE), DNP3, DLMS, Modbus or Procome. Further, the iGW-VM can also process and transfer the data to one or multiple control centers or SCADA master stations using upstream protocols such as IEC 104, IEC 101, TASE2.0/ ICCP (IEC 60870-6), IEC 61850-90-2, DNP3, and Modbus RTU/TCP. Amongst its state-of-the-art features, the iGW-VM is able to provide load shedding functionalities, high accuracy time stamping/processing (<1ms accuracy), as well as straightforward PLC programming/automation according to IEC 61131-3 via the free iConf tool. Porting to Linux & Windows platforms, from servers to embedded systems • Redundant hot-standby architecture • Extremely scalable and adaptable to any particular present and future needs • Simple configuration with iConf too

Open the catalog to page 1

Communication Protocols The iGW-VM can be used as a simple link between serially connected physical devices and logical IEC 61850 devices, as it can be simply configured to map any signal from all sorts of data models onto IEC 61850 logical nodes, whilst also providing IEEE1588 / PTP time synchronization. The iGW was designed to use a high number of protocols and communicate with several control centers at once. Thanks to its full iGrid protocol stack, the iGW-VM can also convert any standard or legacy protocol such as IEC 608705-103, SPAbus, Modbus or DLMS to IEC 61850 GOOSE or MMS, making...

Open the catalog to page 2

Jg i Conf< PHUOCHUUngayl 2-9> e Edit View Project iRTU i Control Help E-- System <E)~ PHUOCHUU ■ COMIo C0M2O C0M3O -C0M4O -COMSo COMGo -C0M7O COMSo ^ Digital Inputs Y" Digital Outputs y Analog Inputs Y" Analog Outputs Y" Counter Inputs ^KFormulaes ] iGrid products, including devices operating with iGW-VM can all be locally and remotely configured and maintained via USB or Ethernet, using iGrid's free iConf tool or standard software tools such as telnet. Alternatively, configuration data can be up- or downloaded via USB flash drive, FTP manager or iConf. We recommend using the iConf tool...

Open the catalog to page 3

Protocol Stack Easy configuration with iConf tool Master/Slave Modbus TCP/UDP and JBUS (master) Master/Slave ModbusRTU Command console with full information on packet exchanges, Local or remote maintenance via USB or Ethernet port Master DLMS Operating System OS Linux or Windows based servers Master Spabus, Mlink, Procome Command console with full information on packet exchanges, on all available protocols SNMP Agent/Manager Internal web server, allowing real time monitoring of the system and all its internal parameters Communication Ports Ethernet and serial port management iGComms...

Open the catalog to page 4All IGrid T&D catalogs and technical brochures

-

iGW

4 Pages

-

iRTUe

4 Pages

-

iGWlite

4 Pages

-

iControl SCADA

4 Pages

-

iRTU

4 Pages