Catalog excerpts

WARNING: Gasoline is a Highly Combustible Fuel.The Improper Use, Handling, or Storage of Gasoline Can be Dangerous. Never Touch or Fill a Hot Engine. 11.Use only pipe, hose and fittings rated for themaximum psi rating of the pump.12.Do not use these pumps for pumping water or otherliquids for human or animal consumption. WARNING: Pump must not be run dry. 1.Always drain and flush pump before servicing ordisassembling for any reason (see instructions).2.Always drain and flush pumps prior to returning unitfor repair.3.Never store pumps containing hazardous chemicals.4.Before returning pump...

Open the catalog to page 2

GAS ENGINE MOUNT Models 9510Pand 9513P9510Pfits most 8 hp gas engines with flange mount and 1" shafts; 9513Pfits most 5 hp gas engines with flange mount and 3/4" shaft. To install pump onto gas engine, first apply anti-seizecompound to gas engine shaft and to inside of pump hollow shaft. Insert key into engine shaft. Next, slide pump onto engine shaft and secure with four hex head bolts. NOTE: Do not force pump onto shaft. Tighten set screws on pump shaft through slots in flange. Check to make sure pump rotates freely by slowly turning over the gas engine. To Prevent Corrosion Flush Pump...

Open the catalog to page 4

Cleanup Of Pump Housing 1.Using the circular bottle-type wire brush with air or handdrill, clean the discharge port, suction port and the sealing areas of the o-ring on the pump casing and mounting flange. [The last step should not be performed on the polypropylene models.]2.After wire brush cleaning, it is recommended that the pumpcasing and mounting flange be further cleaned in a solvent tank to remove rust and corrosion particles. Pump Shaft and Bearing Assembly Removal andReplacement Reassemble if drive end is not to be repaired.Be extremely careful with the new seal. Take special care...

Open the catalog to page 5

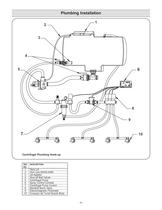

REF.DESCRIPTION NO. 1Tank Lid 2Vent Line #3430-0456 3Jet Agitator 4Shut-off Ball Valves 5Centrifugal Pump 6Spray Control Console 7Centrifugal Pump Control 8Manifold Boom Valve 9Electromagnetic Flowmeter10Compact Jet Turret Nozzle Body -6- >

Open the catalog to page 6

Nozzle Bodies Nozzle bodies with shut-off check valves are recommended to eliminate dripping from the spray tips when the boom valves are shut down. Boom Section Valves For rapid response and reliability,we recommend electric plunger valves be used for boom control. The valves should be sized accordingly to minimize the pressure drop and maximize the flow rate. The boom tubing or hose should be sized accordingly to ensure that a pressure drop in the lines does not occur,causing inconsistent pressures at the nozzles. Agitation Flowmeter The centrifugal pump control contains a manual...

Open the catalog to page 7

THIS WARRANTYIS EXCLUSIVE. HYPRO MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, INCLUDING BUT NOTLIMITED TO ANYWARRANTYOF MERCHANTABILITYOR FITNESS FOR APARTICULAR PURPOSE. Hypros obligation under this warranty is, at HyproҒs option, to either repair or replace the product upon return of the entireproduct to the Hypro factory in accordance with the return procedures set forth below. THIS IS THE EXCLUSIVE REMEDYFORANYBREACH OF WARRANTY.IN NO EVENT SHALLHYPRO BE LIABLE FOR ANYINCIDENTALOR CONSEQUENTIALDAMAGES OF ANYKIND,WHETHER FOR BREACH OF ANYWARRANTY, FOR NEGLIGENCE, ON THE BASIS OF STRICT...

Open the catalog to page 8All Hypro Pressure Cleaning catalogs and technical brochures

-

PRODUCT CATALOG

236 Pages

-

Transfer Pumps

7 Pages

-

Gear Driven

3 Pages

-

Centrifugal Pumps

41 Pages

-

9302 Series

2 Pages

Archived catalogs

-

ULD Sales Sheet

2 Pages

-

ESI Sales Sheet

2 Pages

-

TwinCap Sales Sheet

2 Pages

-

HP Stainless Steel Nozzles

2 Pages

-

UAS Ceramic Nozzles

2 Pages

-

9302 Series Sales Sheet

2 Pages

-

Hydraulic Pump Selection Guide

38 Pages

-

Foam Marker OIPM

20 Pages

-

Cleanload OIPM

12 Pages

-

Series 2100 Versa-Twin OIPM

16 Pages

-

Hydraulic Pressure Washer OIPM

20 Pages

-

PowerLine Plunger OIPM

24 Pages

-

2535S OIPM

12 Pages

-

Series 5200 Piston Pump OIPM

8 Pages

-

Series 5300 OIPM

20 Pages

-

DBS & DBA Diaphragm Pump OIPM

20 Pages