Catalog excerpts

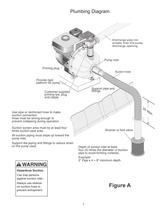

Please Note: It is illegal to ship or transport any hazardous chemicals without United States Environmental Protection Agency Licensing. NOTICE: Settling and/or shifting during operation cancause piping to place excessive strain on the pump and may damage pump case. Set pump on hard level surface. Non-level surfaces may cause the oil sensor in the engine to shut down the unit. 1.Always drain and flush pumps before servicing ordisassembling for any reason.2.Before returning unit for repair, drain out all liquids andflush unit with neutralizing liquid. Then, drain the pump. Attach a tag or...

Open the catalog to page 2

Hazardous Suction. Can trap personsagainst suction inlet.Always use straineron suction hose to prevent entrapment. > 3 size="-1">

Open the catalog to page 3

1.Fuel: Check fuel level in tank, and do not over fill. Usefresh, clean automotive fuel. 1.Idle the engine for 3 to 5 minutes to warm it up. 2.Open the throttle lever to the upper zone after enginehas warmed up.3.Once the pump has primed, you will note a load on theengine; adjust rpms to proper speed for your pumping application. Note: DO NOT FILLFUELTANK WHEN ENGINE IS RUNNING. 2.Engine Oil: Before checking or refilling with engine oil,make sure the engine is stopped and placed on a stable, level surface. Use oil recommended for ambient air temperatures that the engine will be running at....

Open the catalog to page 4

Always flush pump with water or neutralizing agentbefore servicing.PUMPHOUSING DISASSEMBLY Seal replacement requires that the pump be fullyremoved from the engine. Observe carefully the disassembly process to ensure an easy assembly process. Replace all worn and eroded parts.1.Remove spark plug wire from the spark plug forsafety consideration. Remove the 10 bolts and nuts holding the pump casing to the casing cover using a 10mm socket and a 10mm open end wrench. Tap pump casing on the discharge port with a rubber hammer, if necessary, to break it loose from the casing cover. Remove o-ring...

Open the catalog to page 5

Fig. 6 Fig. 7 Fig. 8 Fig. 9 Fig. 10 SEALREPLACEMENTAND PUMPHOUSING ASSEMBLY1.Install slinger ring on engine shaft. (See Figure 5.) 2.Lubricate and install the o-ring around back side ofmetal portion of the seal (See Figure 6). Insert the stationary portion of the new mechanical seal by carefully pushing only on the outer metal ring as you press it into the casing cover. Use a tool with 1-1/2" ID, such as 1-1/2" diameter PVC pipe, 4" long that fits over the carbon face of the seal, but pushes only on the metal ring to insert the seal. The carbon surface of the seal must be facing you during...

Open the catalog to page 6

PROBABLE CAUSE SYMPTOMENGINEPUMPSYSTEM ABCDEFGHIJKLMNOP XXXXXXX Pump works for a while, then stops XXXXXX CAUSECORRECTIVE ACTION 1. ENGINE A.Speed too low.Refer to engine section. B.Rotating and/or reciprocating parts drag.Refer to engine section. C.Speed too high.Maximum engine speed not to exceed engine manufacturers recommendation. D.Loose or broken parts.Refer to engine section. 2. PUMP E.Not primed.Reprime, inspect suction system for air leaks, and/or check assembly. F.Pump takes too long to prime.Check for air leaks or defective check valve.G.Flow through pump completely Locate and...

Open the catalog to page 7

Add Gasoline Fill gas tank with clean, fresh gasoline. This should beunleaded fuel that has an octane rating of 86 or higher. Donot fill the tank to overflowing. Clean up any spilledgasoline before starting the engine. > Engine Safety Precautions: > Fire and explosion hazard. Gasoline canexplode. Store gasoline away from the engine. Add gaso- line to the engine only when the engine is off. > Burn hazard. H ot surface. The engine getsvery hot during operation. Do not touch the engine sur- faces. Keep children away. Allow the engine to cool before moving it indoors. > Deadly fumes. C arbon...

Open the catalog to page 8

Hypro ("Hypro") warrants to the original purchaser of its products (the "Purchaser") that such products will be free from defects in materialandworkmanship under normal use for the period of one (1) year for all products except: oil crankcase plunger pumps will be free fromdefects in material and workmanship under normal use for the period of five (5) years, and accessories will be free from defects in materialand workmanship under normal use for the period of ninety (90) days. In addition, Hypro warrants to the purchaser all forged brass pump manifolds will be free from defects in material...

Open the catalog to page 12All Hypro Pressure Cleaning catalogs and technical brochures

-

PRODUCT CATALOG

236 Pages

-

Transfer Pumps

7 Pages

-

Gear Driven

3 Pages

-

Centrifugal Pumps

41 Pages

-

9302 Series

2 Pages

Archived catalogs

-

ULD Sales Sheet

2 Pages

-

ESI Sales Sheet

2 Pages

-

TwinCap Sales Sheet

2 Pages

-

HP Stainless Steel Nozzles

2 Pages

-

UAS Ceramic Nozzles

2 Pages

-

9302 Series Sales Sheet

2 Pages

-

Hydraulic Pump Selection Guide

38 Pages

-

Foam Marker OIPM

20 Pages

-

Cleanload OIPM

12 Pages

-

Series 2100 Versa-Twin OIPM

16 Pages

-

Hydraulic Pressure Washer OIPM

20 Pages

-

PowerLine Plunger OIPM

24 Pages

-

2535S OIPM

12 Pages

-

Series 5200 Piston Pump OIPM

8 Pages

-

Series 5300 OIPM

20 Pages

-

DBS & DBA Diaphragm Pump OIPM

20 Pages