Catalog excerpts

Hypro medium pressure diaphragm pumps are recom- mended for spraying herbicides, pesticides, liquid fertiliz- ers, and many other hard-to-handle fluids. Low-cost maintenance and almost wear-free operation make these pumps ideal for a wide variety of spraying jobs. Pressure and output are designed for optimum perform- ance of small to medium-sized sprayers. Hypro medium pressure diaphragm pumps can beadapted for male 1-3/8" splined shaft, female 1-3/8" splined shaft, 1" solid shaft, or gear reduction drive options. See kits on page 2. Pumps include a pulsation dampener except for Models 9910-D303, D403, and D503. > Max flow: 3.5 gpm Max pressure: 290 psi Max speed: 3600 rpm 2diaphragms complete with control unit Max flow: 6 gpm Max pressure: 290 psi Max speed: 650 rpm (D252)3600 rpm (D252GRGI) 2diaphragms Max flow: 9 gpm Max pressure: 580 psi Max speed: 550 rpm (D30)3600 rpm (D30GRGI) 2diaphragms > Max flow: 14 gpm Max pressure: 580 psi Max speed: 550 rpm 2diaphragms Max flow: 15 gpm Max pressure: 580 psi Max speed: 550 rpm (D503)3600 rpm (D503GRGI) 3diaphragms Max flow: 7.9 gpm (D303)10.6 gpm (D403) Max pressure: 580 psi Max speed: 550 rpm (D303 & D403)3600 rpm (D303GRGI & D403GRGI) 3diaphragms >

Open the catalog to page 1

Always drain and flush pump before servicing ordisassembling for any reason (see instructions).ՕAlways drain and flush pumps prior to returningunit for repair.Never store pumps containing hazardous chem-icals. ՕDo not pump at pressures higher than the max-imum recommended pressure.Operate the pump between a temperature rangeof 45oto 140oF[7oto 60oC].ՕMake certain that the power source conforms tothe requirements of your equipment.Provide adequate protection in guarding aroundthe moving parts such as shafts and pulleys.ՕDisconnect the power before servicing. Release all pressure within the...

Open the catalog to page 3

box body (Ref. 8). The plugs (Ref. 9) and vent plug(Ref. 13) are all interchangeable for gear reducer mounting convenience.8. Fill the gear case with 90W gear lube. To properlyfill, first tighten bottom plug (Ref. 9); then remove one side plug (Ref. 9) and vent plug (Ref. 13). Filluntil the gear lube is no higher than the mark on thedipstick.9. Replace and tighten the side plug and the vent plug.10. Please apply anti-seize to the motor shaft prior to installing the gearbox. > The Model 9910-KIT1990 control unit is designed forcontrol of pressures to 290 psi and flows up to 6 gpm. It mounts...

Open the catalog to page 7

clamping should be used on all outlet hose connec-tions. 2. Place o-rings (Ref. 110) into groove of relief valvebody (Ref. 105) and discharge flange housing (Ref. 101).3.Assemble the control unit and discharge flangehousing onto the bracket and secure with the bolts and nuts provided.4. Use the high pressure hose to connect pump dis-charge port hose barb to the control unit inlet port hose barb. > Hypro recommends a blue thread locking compound onall threaded fasteners that do not require lock washers. 1. Install mounting bracket (Ref. 29) in desired locationand secure with bolts (Ref. 31)...

Open the catalog to page 8

4. The relief valve bypass port should be connectedback to the liquid tank without restrictions. Do not hook bypass line back to the inlet port or inlet hose.5. Allow the pump to start under low pressure byremoving restrictions on the outlet of the pump. 6. Start the pump and let it run for approximately oneminute at low pressure; then stop the pump and check the oil level in the sight glass. Add Hypro oil if necessary. 7.Adjust the pump to the desired pressure by chang-ing the relief valve setting on the control unit, relief valve or unloader. On pump D252, (See Figure 7) first back out...

Open the catalog to page 9

Remove the oil fill cap, turn the pump upside down and rotate the shaft until oil stops flowing out. (D252 gear reduction oil requirements: use 80-90 wt. gear lube and fill to level hole on gear reduction side.) > D12GRGI and D252 1.After usage, flush the pump with clean water.2. Hypro diaphragm pumps come with oil in thecrankcase. Hypro recommends changing oil after 40 hours of break-in operation and every three months or 500 hours, whichever comes first. Use Hypro oil (part number 2160-0038). Hypro oil is a specially formulated, high-grade, non-detergent, SAE 30 weight oil formulated to...

Open the catalog to page 10

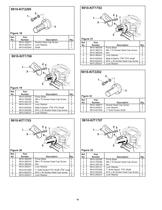

Ref.PartNo.NumberDescriptionQty. 19910-160671Socket Head Cap Screw3 29910-200231Lock Washer3 39910-6216001" Solid Keyed Shaft1 > Ref.PartNo.NumberDescriptionQty. Ref.PartNo.NumberDescriptionQty. 19910-380200Pump Base 2 29910-380210M8 x 75 Socket Head Cap Screw2 39910-380240Nut249910-380241Lock Washer259910-6216001" Solid Keyed PTO Shaft 23/8" long169910-620470M10 x 30 Socket Head Cap Screw3 79910-200231Lock Washer3 19910-320392Pump Base 2 29910-750060M8 x 75 Socket Head Cap Screw2 39910-320130Nut249910-320131Lock Washer259910-6216001" Solid Keyed PTO Shaft1 69910-540300M10 x 30 Socket Head...

Open the catalog to page 18

Bypass hose barb connect directly to tank without restrictions or ball valves. >

Open the catalog to page 20

NOTE: When ordering parts, giveQUANTITY, PARTNUMBER, DESCRIPTION, and COMPLETE MODELNUMBER. Reference numbers are used ONLYto identifyparts in the drawing and are NOTto be used as order numbers. >

Open the catalog to page 24

NOTE: When ordering parts, giveQUANTITY,PARTNUMBER, DESCRIPTION, and COMPLETE MODELNUMBER. Reference numbers are used ONLYto identify parts in the drawing and are NOT to be used as order numbers. >

Open the catalog to page 30

Hypro warrants to the original purchaser of its products (the PurchaserӔ) that such products will be free from defects in materialand workmanship under normal use for the period of one (1) year for all products except: oil crankcase plunger pumps will be free from defects in material and workmanship under normal use for the period of five (5) years, and accessories will be free from defects in material and workmanship under normal use for the period of ninety (90) days. In addition, Hypro warrants to thepurchaser all forged brass pump manifolds will be free from defects in material and...

Open the catalog to page 32All Hypro Pressure Cleaning catalogs and technical brochures

-

PRODUCT CATALOG

236 Pages

-

Transfer Pumps

7 Pages

-

Gear Driven

3 Pages

-

Centrifugal Pumps

41 Pages

-

9302 Series

2 Pages

Archived catalogs

-

ULD Sales Sheet

2 Pages

-

ESI Sales Sheet

2 Pages

-

TwinCap Sales Sheet

2 Pages

-

HP Stainless Steel Nozzles

2 Pages

-

UAS Ceramic Nozzles

2 Pages

-

9302 Series Sales Sheet

2 Pages

-

Hydraulic Pump Selection Guide

38 Pages

-

Foam Marker OIPM

20 Pages

-

Cleanload OIPM

12 Pages

-

Series 2100 Versa-Twin OIPM

16 Pages

-

Hydraulic Pressure Washer OIPM

20 Pages

-

PowerLine Plunger OIPM

24 Pages

-

2535S OIPM

12 Pages

-

Series 5200 Piston Pump OIPM

8 Pages

-

Series 5300 OIPM

20 Pages

-

DBS & DBA Diaphragm Pump OIPM

20 Pages