Website:

Hyperion Materials & Technologies

Website:

Hyperion Materials & Technologies

Group: KKR

Catalog excerpts

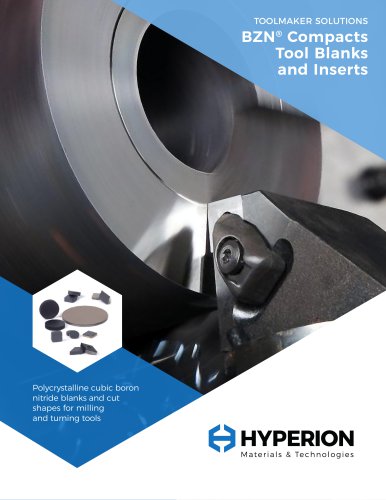

BZN Compacts Tool Blanks and Inserts Polycrystalline cubic boron nitride blanks and cut shapes for milling and turning tools

Open the catalog to page 1

Hyperion manufactures a complete line of high quality polycrystalline cubic boron nitride (PCBN) products for machining ferrous materials. The BZN Compacts product line is designed to provide significantly increased tool life, consistent surface finish, and dimensional control. As a direct result, overall part cost can be significantly decreased, while at the same time gains in productivity as well as cost savings in the total manufacturing operation are successfully achieved. BZN Compacts tool blanks and inserts are available in a wide range of shapes, sizes, and grades for fabrication...

Open the catalog to page 2

- High abrasion resistance - Wear resistance BZN 6000 - Excellent edge quality and retention - Superior impact strength - Produces fine surface finishes - Severe interrupted cuts - Pearlitic gray cast iron - Tool and die steels - Hard facing alloys - Sintered alloys - Finishing of Ni- and Co-based superalloys - Turning of sintered carbide (>16% Co content) - Excellent impact resistance - Good chemical stability - Continuous to interrupted cuts - Cast iron - Powder metal alloys - Tool steel milling - Improved microstructural homogeneity - Superior impact resistance - Improved wear and...

Open the catalog to page 3

BENEFITS OF BZN® COMPACTS CARBIDE SUPPORTED GRADE - Superior edge toughness - Suitable for both roughing and finishing cuts Continuous to medium interruption Hardened steels Powder metal machining CV joint applications (milling and turning) Typical speeds @ 140-220 m/min - Superior edge toughness - Good flank and crater wear resistance - Suitable for both roughing and finishing cuts Mild to heavy interruption Valve seat machining CV joint applications Typical speeds @ 80-150 m/min SOLID PCBN GRADE - Tailored particle distribution for higher cutting speeds - High fracture toughness - Excellent...

Open the catalog to page 4

EDM AND LASER CUT SEMI-FINISHED INSERTS PRODUCT CODE REFERENCE BZN 7000S/7400S grades are laser cut as the material is not conductible. Therefore, the IC is oversized due to laser chipping and kerf, Additional sizes and shapes may be available upon request. BZN HPT130, HPT135, V-Series, and VS-Series can be ordered as full top inserts upon request. Maximum thickness is 3.2 mm. To see size and availability, please visit www.HyperionMT.com. THICK BZN 9100 COMPACTS FOR ENDMILLS Thick BZN 9100 Compacts cut parts offer a tungsten carbide base with a thicker CBN layer. The BZN 9100 Compacts parts...

Open the catalog to page 5

BZN V-SERIES COMPACTS Machining of hardened steels continues to be ever more challenging as alloying compositions change and machine tools and fabrication features evolve. The variety of applications at any end user requires a stocking of multiple PCBN grades. Thus, there is an inherent need for PCBN grades that can adequately cover these wide ranging applications. With this motivation, Hyperion introduced the BZN V-Series, i.e., Versatility-Series, to allow customers maximum flexibility in machining of hardened ferrous materials. The BZN V-Series grades are designed to provide versatility...

Open the catalog to page 6

BZN V20 PCBN GRADE FOR HARDENED STEEL MACHINING - Designed for continuous to mild interrupted turning - Excellent balance of flank and crater wear resistance - Good chipping resistance - Suitable for both wet and dry conditions. Work Material - 100Cr6, HRc 60-62 Insert CNGA120408 Vc = 130 m/min, ap = 0.25 mm, f = 0.1 mm/rev, dry Work Material - 100Cr6, HRc 58 Taper bearing Vc = 200 m/min, ap = 0.17 mm, f = 0.15-0.2 mm/rev, wet APPLICATIONS BZN Grade V20 is recommended for machining: - Hardened steel (wet and dry) - Valve seat materials - Cold work tool steels. GRADE SUMMARY Grade To see...

Open the catalog to page 7

BZN V25 PCBN GRADE FOR HARDENED STEEL MACHINING - Designed for continuous to medium interrupted applications - Good flank and crater wear resistance at higher cutting speeds - Superior edge toughness - Suitable for both roughing and finishing cuts. Work Material - 21NiCrMoS2, HRc 58-62 Insert CNGA120408 Vc = 200 m/min, ap = 0.15 mm, f = 0.2 mm/rev, dry Work Material - 100Cr6, HRc 60-62 Interrupted turning Vc = 160 m/min, ap = 0.2 mm, f = 0.15 mm/rev APPLICATIONS BZN Grade V25 is recommended for: - Medium interrupted turning - Powder metal machining - CV joint applications. GRADE SUMMARY...

Open the catalog to page 8

BZN V35 PCBN GRADE FOR HARDENED STEEL MACHINING - Designed for mild to heavy interrupted applications - Superior edge toughness - Suitable for both roughing and finishing cuts. Competitor PCBN Competitor PCBN DISTANCE MACHINED (km) Work Material - 100Cr6, HRc 60-62 Interrupted turning Vc = 160 m/min, ap = 0.2 mm, f = 0.15 mm/rev Powder Metal Valve Seat Machining Vc = 100 m/min, f = 0.1 mm/rev Plunge cut APPLICATIONS BZN Grade V35 is recommended for: - Heavy interrupted turning - Valve seat machining - CV joint applications. GRADE SUMMARY Grade To see size and availability, please visit...

Open the catalog to page 9

CUTTING SERVICES HYPERION UTILIZES THE LATEST IN EDM TECHNOLOGY Our service shop is capable of performing precision cutting services: - Complete your cut order in five business days or less from the day the order is received. - Each piece is cleaned and visually inspected to ensure you receive the highest level of quality and to minimize your internal processing time. - Precision cutting of PCBN blanks includes standard shapes, customer special shapes, through holes, tight tolerance, relief angles and carbide chamfers. Standard cut product tolerance for PCBN * Special = if not standard...

Open the catalog to page 10

TS-PCBN 1903-004 ENG LT Copyright © Hyperion Materials & Technologies - All rights reserved HYPERION Materials & Technologies

Open the catalog to page 12All Hyperion Materials & Technologies catalogs and technical brochures

-

Carbide Rod_HyperionMT

48 Pages

-

Cutting Insert Saw Tips

8 Pages

-

BZN Compacts - Cutting Inserts

12 Pages

-

Insert Blanks_EN_HyperionMT

8 Pages

-

Carbide Gear Hob Blanks

2 Pages