Website:

Hydropa

Website:

Hydropa

Catalog excerpts

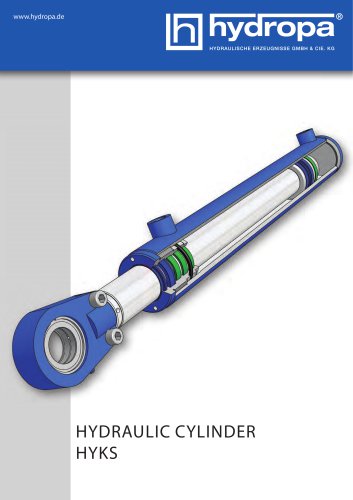

The hydraulic cylinder, as a link between hydraulic control Page and the machine, is suitable for use in many areas of industry, such as pressing and joining applications, the chemi- General 3 cal industry or tool making. Hydraulic cylinders can also be used without a problem in areas having extremely high or Operating instructions 4 low ambient temperatures. Basis of calculations for hydraulic cylinders 6 The Hydropa HYKS series of hydraulic cylinders exhibit a sturdy welded/bolted construction with honed and seam- Technical data 8 less cylinder barrels and ground, precision...

Open the catalog to page 2

300 bar 0,5 m/s to 4 m/s -30° C to +80° C any piston-0 > 50 mm transducer or inductive proximity switch GENERAL CHARACTERISTICS Piston diameter: 40 to 200 mm Perm. max. operating pressure: 250 bar,,.----'''' Test pressure: Piston speed: Temperature range: Mounting position: Damping adjustable: Distance measurement: • PTFE • POM • PU The seals are designed for use with hydraulic oils in accordance with DIN 51524 and DIN 51525 and a temperature range of -30 ° C to +80 ° C. Seals for other temperature ranges and operating media as well as for other cylinder and rod materials are...

Open the catalog to page 3

OPERATING INSTRUCTIONS STORAGE In order to ensure a long shelf life of the bearing surfaces and seals of hydraulic cylinders, and to protect them against corrosion, the piston rods should be retracted and the cylinders filled completely with oil. It is important to ensure that no air is trapped in the cylinder and that the connections are sealed airtight. The piston rod thread, the free rod end, and ball and socket joints should be coated lightly with anti-corrosion grease. If the cylinders are stored at fluctuating ambient temperatures, they must be protected with a pressure relief valve...

Open the catalog to page 4

HYDRAULISCHE ERZEUGNISSE GMBH & CIE. KG REPLACMENT PARTS When ordering spare parts, always include the imprinted order number, which is located to the right of the base-end connection (in reference to the piston rod). PLEASE NOTE : Installation, repair and commissioning of cylinders may be carried out only by trained specialist personnel with the necessary expertise. Hydropa assumes no liability for any damage resulting from installation, repairs and commissioning, which were not carried out or commissioned by Hydropa.

Open the catalog to page 5

PISTON FORCES PISTON SPEED p = pressure A = effective piston surface F = effective piston force d1 = piston diameter d2 = piston rod diameter µ = efficiency factor of the cylinder Q = volumetric flow rate A = effective piston surface v = piston speed Effective piston force: F=p*A*μ Piston speed: v=Q/A given: Hydraulic cylinder with d1 = 100 mm, d2 = 70 mm, μ = 0.85, p = 60 bar [ 1 bar = 10 N/cm2 ] given: Hydraulic cylinder with d1 = 50 mm, d2 = 36 mm, Q = 12 l/min needed: Effective piston force (F) needed: Piston speed (v) retraction: retraction: F=p*A*μ = 600 N/cm2 * ( π * ( ( 10 cm )2 - (...

Open the catalog to page 7

TECHNICAL DATA Buckling calculation The calculation of buckling SK is carried out according to Euler, whereby in simplified terms the piston rod and tube can be regarded as a slender rod. Euler case 2 using articulated / swivel eye as an example (A + add. meas.) Euler case 3 using head flange as an example The tables show the permissible stroke in mm at buckling stress (compressive stress) according to Euler with 3.5 times the safety factor and flexibly guided load. : per. stroke length in mm : modulus of elasticity 2,1 * 105 for steel in N/mm2 : moment of area im mm4 for circular...

Open the catalog to page 8

Mounting type head flange HYC-

Open the catalog to page 9

MOUNTING METHODS Optional: Piston rod eye, fork head We also build other models according to customer specifications. articulated eye, base end HYC-...-G-... base flange HYC-...-B-... head flange HYC-...-K-... swivel eye, base end HYC-...-S-... tangential feet HYC-...-T-...

Open the catalog to page 10

HYDRAULISCHE ERZEUGNISSE GMBH & CIE. KG PRODUCT KEY HYDRAULIC CYLINDER SERIES: HYC 1 MOUNTING TYPE G = articulated eye S = swivel eye K = head flange B = base flange M = trunnion T = tangential feet 2 PISTON DIAMETER (mm) 3 ROD DIAMETER (mm) ... =piston rod material 20MnV6 (standard) 4 ROD DIAMETER (mm) (for synchronous cylinder only) ... = piston rod material 20MnV6 (standard) 5 STROKE (mm) 6 OIL PORT THREAD = pipe thread = metric thread 7 TYPE OF MOUNTING ON PISTON ROD „no specification'^ Piston rod thread GIHR-K = Piston rod eye,clampable SA-K = Swivel eye, clampable GK =...

Open the catalog to page 11

DIFFERENTIAL CYLINDER WITH ARTICULATED / SWIVEL EYE HYC-G Venting Damping- and Differential cylinder with articulated / swivel eye

Open the catalog to page 12

HYDRAULISCHE ERZEUGNISSE GMBH & CIE. KG DIFFERENTIAL CYLINDER WITH BASE FLANGE Differential cylinder with base flange Type

Open the catalog to page 13

DIFFERENTIAL CYLINDER WITH HEAD FLANGE L + Stroke

Open the catalog to page 14

HYDRAULISCHE ERZEUGNISSE GMBH & CIE. KG Differential cylinder with trunnion Type

Open the catalog to page 15

Differential cylinder with tangential feet

Open the catalog to page 16

HYDRAULISCHE ERZEUGNISSE GMBH & CIE. KG

Open the catalog to page 17

END POSITION SENSING AND LINEAR POSITION MEASUREMENT SYSTEM END POSITION SENSOR + available either with plug-in connector or moulded PU cable + high operational safety due to the detection of end position directly at the piston + lower installation costs, no external mechanism necessary + can be integrated into all series LINEAR POSITION MEASUREMENT SYSTEM + impervious to shock, vibration, temperature, contamination and moisture + wear and maintenance-free due to non-contact detection of the measuring position + absolute output signal, even after a power interruption, no homing run required...

Open the catalog to page 18

CYLINDER REQUEST FORM name of company _________________________________ postal code/city previous order customer number _________________________________ series: HYKS o venting both ends Mounting type: o base-end bearing o trunnion o articulated eye, clampable o tangential feet o swivel eye, clampable o custom mount o fork head, clampable o seal with retaining function o stainless steel, chrome-plated o seal for fire resistant fluids Technical data: Stroke speed: test pressure Type of use: purpose of the cylinder: _____________________________________________ installation location: o...

Open the catalog to page 19All Hydropa catalogs and technical brochures

-

Data sheet HYKS-Series

20 Pages

-

Data sheet MPF 100

3 Pages

-

Data sheet MPF 030

3 Pages

-

Data sheet Accessiors

34 Pages

-

Data sheet ZA6RE

1 Pages

-

Data sheet ZAH6-R

4 Pages

-

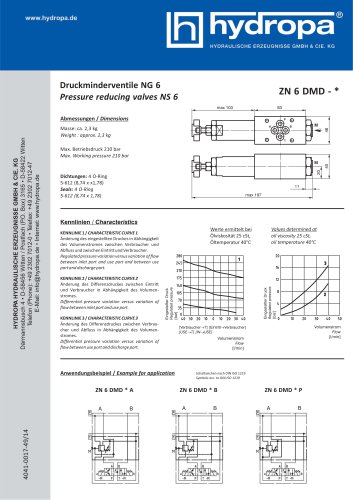

Data sheet ZN6DMD

1 Pages

-

Data sheet ZN6DB-VS AB

1 Pages

-

Data sheet ZN6DB-VS A/B/P

1 Pages

-

Data sheet ZN6DB

1 Pages

-

Data sheet ZN6DR

4 Pages

-

Data sheet WE10AH

11 Pages

-

Data sheet WE6AH

14 Pages

-

Data sheet SPA/SPG pumps

9 Pages

-

Datenblatt DS-104 / EX

8 Pages

-

Data sheet DS-802

2 Pages

-

Datenblatt DS-4*7 / 4*2

10 Pages

-

Data sheet DS-507/502

8 Pages

-

Data sheet DS-307/302

8 Pages

-

Data sheet DS-117/112

8 Pages

-

Data sheet HY-3.SM

16 Pages

-

Overview special power packs

4 Pages

-

Data sheet KA-Power packs

4 Pages

-

DS-307 / 302

8 Pages

-

DS-507 / 502

8 Pages

-

DS-4*7 / 4*2

4 Pages

-

WE 10 AH

11 Pages

-

HYDRAULIC CYLINDERS

20 Pages

-

DS-117 / DS-112

8 Pages

-

2 SPG

9 Pages

-

ZAH10 DR

1 Pages

-

WE6AH

14 Pages

-

DMH-630 R

11 Pages

-

Hand pumps

12 Pages

-

ZN 6 DBS - * - AB

1 Pages

-

ZA 6 RE -*

1 Pages

-

Z 6 R *

1 Pages

-

ZN 6 DMD - *

1 Pages

-

ZN 6 DB - *

1 Pages

-

ZN 6 DR-*

4 Pages

-

3 SP-B

4 Pages

-

2 SP-B

4 Pages

-

1 SP-B

4 Pages

-

DS-802/M/B

2 Pages

-

DS-4*7/4*2

4 Pages

-

DS-507 / DS-502

8 Pages

-

DS-307 / DS-302

8 Pages

-

Special - Power Packs

4 Pages

-

KOMPAKT-AGGREGATE

4 Pages

-

HYDRAULIC MOTORS

16 Pages

-

ATEX-PRESSURE SWITCH

1 Pages

-

SPECIAL POWER PACKS

4 Pages

-

MINI POWER PACKS

12 Pages

Archived catalogs

-

DS-117/112

8 Pages

-

Rotary Actuators

16 Pages