Catalog excerpts

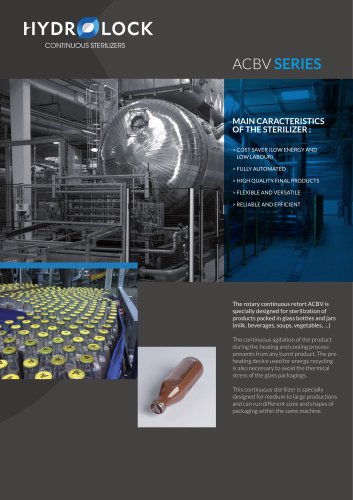

CONTINUOUS STERILIZERS ACCT SERIES MAIN CARACTERISTICS OF THE STERILIZER : > COST SAVER (LOW ENERGY AND LOW LABOUR) > FULLY AUTOMATED > HIGH QUALITY FINAL PRODUCTS > FLEXIBLE AND VERSATILE The rotary continuous retort ACCT is specially designed for sterilization of food packed in tin cans of retortable plastic trays and bowls. The continuous agitation of the product during the heating and cooling process prevents from any burnt product. The continuous and agitated process allows HTST processes (High Temperature Short Time) which are recognized to improve organoleptic qualities and colours. This continuous sterilizer is specially designed for medium to large productions and can run different sizes and different materials within the same machine depending on packaging.

Open the catalog to page 1

ACCT SERIES > Automated loading and unloading > No lag time (or waiting time) > User friendly HMI with maintenance trackers > Continuous control and record of critical parameters > Multi recipe system > Remote access for maintenance > Certifications CE, TUV, ASME > Multi PLC brands available ( Rockwell, Schneider, Siemens ...) > Special design on request Tubular carriers for cans PRODUCTION SPEED Speed given for 15 min holding time and 1/2H cans D73xH110mm - equivalent to 15 Oz 8 rue des Fontenelles, Parc d’activité de la forêt 44140 LE BIGNON FRANCE

Open the catalog to page 2All HYDROLOCK catalogs and technical brochures

-

General brochure

4 Pages

-

STERIPILOT 60 - ENGLISH

2 Pages

-

HYDROLOCK - ACS SERIES

2 Pages