Catalog excerpts

Hydraulic Tensioners

Open the catalog to page 1

Because ensuring a leak-free solution is critical. It has to be Hydratight. For more than 100 years, Hydratight has provided world-class bolted joint solutions, assessing and managing joints to ensure leak-free start-ups. Today, we continue to set international standards in joint integrity—but we’re so much more than just a bolting and on-site machining company. Because even the tiniest leak can be costly and time consuming to repair, we manage every joint on a project for leak-free start-ups and production, which in turn removes the threat of environmental impact caused by unsafe joints....

Open the catalog to page 2

Tensioning Solutions Hydratight’s extensive line of tensioners are suitable for either topside or subsea applications. Our tools are available through sales, rental, or with on-site technical support. Safe, reliable, and repeatable, the use of hydraulic tensioners offers many advantages over less accurate tightening methods: • Direct: Tension is applied directly to stretch the bolt, so no need to fight against friction or losses. • Accurate: The applied load is controlled very accurately, because it is directly proportional to the pressure applied to the tensioner. • Calculated: The load...

Open the catalog to page 3

HydraMax® Tensioners With its compact fit and high load generation, Hydratight’s HydraMax® Topside Tensioner has been cleverly designed to fit all standard flanges, including ANSI, API and compact flanges based on Norsok L005. HydraMax® tools have been designed to generate high bolt loads associated with compact flanges, while providing versatility for maximum bolt coverage. Incorporating the proven sealing technology used in Hydratight’s Aquajack® Tensioner line, the HydraMax® series combines the reassurance of trusted technology with the usability of simple service operations. Although...

Open the catalog to page 4

Hydratight’s HL Tensioners provide a simple, safe, accurate and time saving method for tightening topside bolts and studs, maximising economy and versatility by utilising common hydraulic heads with interchangeable bridges, sockets and pullers. Common hydraulic heads of the HL Tensioners enable the maximum number of bolt diameters to be covered with the minimum number of tools. Colour coding of the hydraulic heads ensures easy identification. Features: • Maximum working pressure 1034 bar (15 000 psi) • All tools have 15 mm (0.59") stroke except HT02 stroke = 6 mm (0.24") and HT01 stroke = 8...

Open the catalog to page 7

AquaMax® Tensioners Hydratight’s AquaMax® Subsea Tensioners are tools specifically designed to tension compact flanges as well as all standard ANSI, API and MSS* types. AquaMax® offers a high load capacity on a wide variety of applications—up to 30% more than traditional tensioners. Comprising 19 bolt diameter specific tools, with eight tools forming the core range, AquaMax® Tensioners feature Hydratight’s Aquajack® industry leading quick fastening nut technology, guaranteed to save time and increase efficiency. Primarily for use on subsea applications, each tool within the core...

Open the catalog to page 9

AquaMax® Tensioners * Requires reaction nut step-up washer.

Open the catalog to page 10

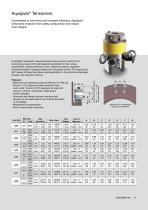

Hydratight's Aquajack® subsea tensioners allow divers to perform the tensioning process with tools designed specifically for their unique requirements. Easily positioned in poor visibility conditions, Aquajack® tensioners feature a compact design and long piston stroke. The unique Split Nut® design of these tools allows rapid application to long bolts and damaged threads, and rapid tool removal. Features: • Maximum tool operating pressure 1500 bar (21 750 psi) • 30 mm (1.18") maximum piston stroke for tools AJ2 to AJ8; 20 mm (0.79") maximum for tools AJ0 and AJ1; all tools incorporate...

Open the catalog to page 11

Our global network means that you can rely on the right people, products, and services wherever you are in the world. Email us at: solutions@hydratight.com Or find your local representative at: hydratight.com/contact Hydratight provides support through strategic service centers, and in additional locations worldwide through channel partners.

Open the catalog to page 12All Hydratight catalogs and technical brochures

-

Portable Boring Bar Brochure

8 Pages

-

Torque Solutions

16 Pages

-

Wind Energy Brochure

8 Pages

-

Subsea Solutions Brochure

12 Pages

-

MORGRIP® Connector Brochure

8 Pages

-

Hydratight Corporate Brochure

26 Pages

-

Ultrasonic Load Monitoring

8 Pages

-

Electric Tensioner Pump

1 Pages

-

Hydraulic Tensioner Pump

1 Pages

-

PowaPak Air Ultra

2 Pages

-

digital turning tool

2 Pages

-

jims

16 Pages

-

Rental Services

4 Pages

-

corporate brochure

28 Pages

-

Hydratight Nuclear Brochure

8 Pages

-

Wind Energy Brochure

8 Pages

-

Subsea Brochure

12 Pages

-

Product and Service Brochure

8 Pages

-

Nutsplitter

1 Pages

-

Drive Motors

1 Pages

-

Hydraulic Power Supply Units

1 Pages

-

Trunnion Grinder

1 Pages

-

Tire Grinder

1 Pages

-

Hand Hole Grinder

1 Pages

-

Oval Manway Seat Grinder

1 Pages

-

XYZ Keyway Cutter

1 Pages

-

Keyway Cutting Machine

1 Pages

-

314 Beveler

1 Pages

-

BU Facer

1 Pages

-

Mini Mill

1 Pages

-

Portable Milling Machine

1 Pages

-

QD Boring Bar

1 Pages

-

Portable Boring Bar

1 Pages

-

Pedestal Valve Boring Bar

1 Pages

-

Axial Feed Module

1 Pages

-

Clamshell Casing Cutters

1 Pages

-

MM180 Clamshell

1 Pages

-

HD Clamshell

1 Pages

-

MS clamshell

1 Pages

-

NB clamshell

1 Pages

-

MC clamshell

1 Pages

-

DL Ricci Clamshell Brochure

7 Pages

-

PowaPak Electric data sheet

2 Pages

-

PowerPak Air Ultra

2 Pages

-

PowaPak Air

2 Pages

-

Torque Brochure

8 Pages

-

Aquajack Tech Data Sheet

1 Pages

-

PS Tensioner

1 Pages

-

HL Tensioner

1 Pages

-

TensionMax

12 Pages

-

QuickFace brochure

2 Pages

-

GTB2 BEVELLER – DATA SHEET

1 Pages

-

LowProfileTBS

1 Pages

-

RicciMachiningCatalog

42 Pages

-

PortableMilling

1 Pages

Archived catalogs

-

Mini Mill

1 Pages

-

Hand Hole Grinder

1 Pages

-

End Prep Facer

1 Pages

-

BU Facer

1 Pages

-

Axial Feed Module

1 Pages

-

MS Clamshell

1 Pages

-

MC Clamshell

1 Pages