Website:

HYDRAFORCE

Website:

HYDRAFORCE

Catalog excerpts

FIVE-YEAR LIMITED WARRANTY All HydraForce products carry a five-year limited warranty against defects in material and workmanship. For full warranty information see page the last page of this catalog.

Open the catalog to page 2

A Word About Safety WARNING READ THIS DOCUMENT BEFORE INSTALLING OR USING HYDRAFORCE PRODUCTS. IMPROPER SELECTION, IMPROPER USE, USE BY ANYONE OTHER THAN TRAINED USERS HAVING APPROPRIATE TECHNICAL AND MECHANICAL EXPERTISE, OR FAILURE OF HYDRAFORCE PRODUCTS OR RELATED ITEMS RESULTING THEREFROM CAN CAUSE DAMAGE TO EQUIPMENT OR PROPERTY, SERIOUS PERSONAL INJURY, OR DEATH. This document and other information from HydraForce, its subsidiaries and authorized distributors (collectively “HydraForce”) together only provide product installation guidelines and product or system usage options, each of...

Open the catalog to page 3

is a new concept in hydraulic controls from HydraForce. It takes the best combination of cartridge valves and integrates them into optimally designed manifolds for cylinder and motor control. INTEGR8 is the fastest way to arrive at efficient, reliable hydraulic control solutions. Here's how to INTEGR8 your application: 1. Start with the function you need - flow control or directional control, direct-acting or pilot-operated. 2. Choose the INTEGR8 component for the function, using the Table of Contents in this catalog. If you are using i-Design to build your circuit, select the INTEGR8...

Open the catalog to page 4

INTEGR8 - Engineered Hydraulic Control Solutions Here are 8 reasons to INTEGR8: Innovation - Expand your creative options with the largest range of performance-optimized cartridge valves in the industry. Cartridge valve and manifold system technologies provide performance options and feature flexibility unsurpassed by alternative valve configurations. System Efficiency - Cartridge valves can be combined and uniquely packaged to optimize machine efficiency, improve operator control, and integrate multiple functions into a common control scheme. Different-sized components can be inter-mixed...

Open the catalog to page 5

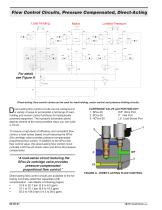

Flow Control Circuits, Pressure Compensated, Direct-Acting Direct-acting, flow control valves can be used for load-holding, motor control and pressure limiting circuits. irect-acting flow control circuits can be configured in a variety of ways to accomplish a full range of loadholding and motion control functions for hydraulically powered equipment. The hydraulic schematic above depicts several of the many possible ways you can build a circuit. To ensure a high-level of efficiency and consistent flow control, a load-sense based circuit featuring the SPxx20x cartridge valve provides...

Open the catalog to page 6

Theory of Operation - Direct-Acting Flow Control For simplicity, the load hold valve downstream of the work port (WP) has been omitted. In Figure A - DIRECTACTING FLOW CONTROL, all products are shown at rest and with no pressure applied to the inlet. Schematic showing flow control WP In Figure B - DE-ENERGIZED, the pump is on and system pressure is fed to the inlet of the flow control valve. The compensator closes to block the flow of oil to the SP flow control. When the solenoid coil is energized (Figure C ENERGIZED), oil is allowed to flow to the work port. The control pressure drop...

Open the catalog to page 7

Direct-Acting, Pressure Compensated, Normally Closed DESCRIPTION A combination of valves working together to provide optimal control of hydraulically powered functions. This direct-acting, pressure-compensated product controls flow proportionally in response to a change in current. Valves in circuit include: SPxx-20x flow control valve ECxx-32 pressure compensator HCVxx-20 check valve For applications requiring low work port leakage, the use of a pilot-operated check valve or counter balance valve is suggested. CARTRIDGE VALVE and PORTING KEY 1 2 3 WP Work Port LS Load Sense Port P Inlet...

Open the catalog to page 8

Performance Charts - Standard Fine Metering SPxx-20 SP08-20 Flow vs. Pressure Compensation with EC08-32 @ 1200 mA 250 psi —— 150 psi 80 psi SP08-20 Flow vs. Current with EC08-32 Compensator 80 psi 250 psi —— 150 psi 18.9/5.0 PRESSURE bar/psi FLOW lpm/gpm FLOW lpm/gpm SP08-20 Pressure Drop With Current at 100% FLOW lpm/gpm DIFFERENTIAL PRESSURE bar/psi SP10-20 Flow vs. Pressure Compensation with EC12-32 @ 1200 mA 220 psi —— 80 psi SP10-20 Flow vs. Current Compensation with EC12-32 220 psi —— 80 psi PRESSURE bar/psi FLOW lpm/gpm FLOW lpm/gpm SP10-20 Pressure Drop With Current at 100% SP12-20...

Open the catalog to page 9

Performance Charts - Linear Metering Option SPxx-20A SP08-20A Flow vs. Pressure Compensation with EC08-32 @ 1200 mA 250 psi —— 150 psi 80 psi SP08-20A Flow vs. Current with EC08-32 Compensator 250 psi —— 150 psi 80 psi SP08-20A Pressure Drop With Current at 100% 45.5/650 PRESSURE bar/psi FLOW lpm/gpm FLOW lpm/gpm DIFFERENTIAL PRESSURE bar/psi SP10-20A Flow vs. Current Compensation with EC12-32 220 psi —— 80 psi PRESSURE bar/psi FLOW lpm/gpm SP10-20A Pressure Drop With Current at 100% FLOW lpm/gpm DIFFERENTIAL PRESSURE bar/psi SP12-20A Flow vs. Current with EC16-32 Compensator 200 psi —— 80...

Open the catalog to page 10

Ordering Information - SPxx-20 and SPxx-20A Metering Options Flow vs. current performance for standard fine and linear metering is charted on the adjacent graph. To specify the Linear Metering Option, add an "A" to the valve model code. See the To Order section. FLOW lpm/gpm (Increasing) HydraForce offers a choice of two metering options on its SPxx-20 cartridge valves. The standard metering option provides fine metering for smooth control. For applications that require extra flow capacity rather than fine metering, a linear metering option is available. TO ORDER To order, refer to ordering...

Open the catalog to page 11

Direct-Acting, Pressure Compensated, Normally Open DESCRIPTION A combination of valves working together to provide optimal control of hydraulically powered functions. This direct-acting, pressure-compensated product controls flow proportionally in response to a change in current. Valves in circuit include: SPxx-21x flow control valve ECxx-32 pressure compensator HCVxx-20 check valve For applications requiring low work port leakage, the use of a pilot-operated check valve or counter balance valve is suggested. CARTRIDGE VALVE and PORTING KEY 1 2 3 WP Work Port LS Load Sense Port P Inlet Port...

Open the catalog to page 12All HYDRAFORCE catalogs and technical brochures

-

INTEGR8

4 Pages

-

H-Series High Pressure Valves

12 Pages

-

HTD10-40

4 Pages

-

Full Line Products Guide

28 Pages

-

Material Handling Solutions

4 Pages

-

Harvesting

8 Pages

-

Wheel Loaders

8 Pages

-

Excavators

8 Pages

-

Tractors

8 Pages

-

2-002

1 Pages

-

Directional Sandwich Valves

4 Pages