Website:

HUSKY INJECTION MOLDING SYSTEMS

Website:

HUSKY INJECTION MOLDING SYSTEMS

Catalog excerpts

Hot Runners and Temperature Controllers Better parts, faster cycles Complete tooling solutions Application specific solutions Pristine gate quality Fastest cycles Fast color change Accurate, reliable temperature control Resin testing Mold-filling analysis Mold process optimization Proactive maintenance and refurbishment Leakproof guarantee It all starts with the part Husky works to gain a detailed understanding of a customers' business and project requirements at the tooling level. This parts first approach reflects our goal of offering melt delivery solutions optimized for each application—helping customers bring products to market faster while achieving the highest levels of quality at the lowest part cost. Our value-added services include in-depth application review and recommendation, resin testing, flow simulation, finite element analysis, 24-hour service parts support and local service. Offering a complete tooling solution, Husky hot runners are available in both hot tip and valve gate configurations depending on application requirements and are available as complete hot halves consisting of a manifold, Ultra nozzles and plates, supported by an integrated Altanium® temperature controller. Our technologies help customers to minimize waste and increase production efficiencies. By optimizing the entire melt delivery system we can ensure best gate quality, cavity-tocavity balance and fast color changes.

Open the catalog to page 1

Complete hot halves with plates Every hot runner we build is optimized for its specific application. Our complete systems are fully tested prior to shipment, are delivered ready to bolt on and run and are backed by a three-year leakproof guarantee. With a regular three-year refurbishment process, we can offer our customers an extended life-time leakproof guarantee. Our systems experience includes: • Low cavitation • PRONTO® systems for fast delivery and reduced cost • High cavitation • Tight pitch • Stack systems up to 2 x 96-drops • Multi color and multi-material • Variety of stem...

Open the catalog to page 2

Products Ultra nozzles Husky’s market-proven Ultra nozzle family is engineered for reliability and performance. Ultra nozzles use advanced tip technology and optimized materials to deliver exceptional performance. Ultra nozzles offer the flexibility of hot tip and valve gate solutions with standard gating options available over a wide range of applications. • Five nozzle sizes • Melt channel diameters from 4 mm to 18 mm (0.16" – 0.7") • Over 50 gating styles • More than 30 standard nozzle lengths Custom and configurable hot runners All Husky hot runners are optimized for customer specific...

Open the catalog to page 3

Support Flow simulation Predicting filling behavior at the part design stage can reduce trial and error and development costs, as well as improve speed to market. Our flow simulation team offers a complete solutions approach to improving productivity. Flow simulation examines polymer flow behavior when injected into the cavity (fill, pack, cool analysis) and once ejected (warpage analysis). Our dedicated team is able to review filling behavior providing the following benefits: Part design • Determine the optimal number of gates, gate location and size, weld line location, fiber orientation...

Open the catalog to page 4

Local Husky facilities provide up-front testing capabilities to help ensure tooling programs are successful. Regular hot runner refurbishment ensures peak performance. Refurbishment Proper maintenance can significantly extend tool life. Husky’s refurbishment services provide a cost-effective solution to ensure improved productivity and uptime. With our experience, advanced equipment and factory support, we can restore your system to “like new” condition. This costeffective service includes: • Manifold, plate and component inspection • Cleaning and part replacement • Assembly and final...

Open the catalog to page 5

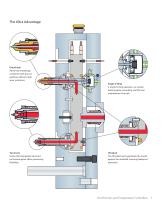

The Ultra Advantage UltraGuide For valve gate applications, UltraGuide® technology pre-aligns the valve stem prior to entering the gate area achieving excellent gate quality. • Reduced gate and stem wear—up to five million cycles with no visible wear • Cylindrical shut-off for superior gate quality across a range of operating temperatures • Thermally conductive tip component for easy start-up and wide processing window Ease of maintenance Ultra Nozzles for hot tips and valve gates allow for convenient maintenance and replacement of wear items. • Tips, tip retainers, nozzle thermocouples and...

Open the catalog to page 6

UltraGuide Advanced metallurgy combined with precise guidance delivers high wear resistance. Single O-Ring A single O-Ring operates in a cooled backing plate, extending seal life and maintenance intervals. Tip inserts Easily interchangeable tip insert on thermal gates offers processing flexibility. UltraSeal The UltraSeal spring preloads the nozzle against the manifold, ensuring leakproof operation. Hot Runners and Temperature Controllers

Open the catalog to page 7

Altanium Temperature Controllers Altanium controllers are designed to provide the most accurate temperature control possible using distributed control and Active Reasoning Technology (ART). Distributed control offers the fastest reaction times by placing the heater signals and power switching directly on the control board. ART optimizes the control of each individual heater in the mold, automatically selecting the best possible algorithm for each heater. Recognized as the easiest controller to operate, Altanium features simple to navigate user interfaces. With accurate temperature control...

Open the catalog to page 8All HUSKY INJECTION MOLDING SYSTEMS catalogs and technical brochures

-

Altanium Neo5

182 Pages

-

Schöttli® Medical Molds

16 Pages

-

UltraSync-E Technology

2 Pages

-

UNIFY™

2 Pages

-

Shotscope NX

2 Pages

-

ultra helix valve gate

4 Pages

-

Pro-Act Program

4 Pages

-

PowerPro G

2 Pages

-

H-PET AE System

4 Pages

-

Altanium Servo Control

4 Pages

-

Ultra SideGate

2 Pages

-

Ultra Helix TM Valve Gate

2 Pages

-

Ultra 350 Nozzles

2 Pages

-

Ultra 1000 Nozzles

2 Pages

-

Ultra 250 Nozzles

2 Pages

-

Express conversion Programs

2 Pages

-

Encore program

4 Pages

-

Ultra SideGate

2 Pages

-

UNIFY

2 Pages

-

Top Entry Robots

2 Pages

-

Thinwall Packaging

4 Pages

-

Specialty Closures

2 Pages

-

ShotscopeNX

2 Pages

-

PRONTO Hot Runners

4 Pages

-

ProAct Program

4 Pages

-

Machine Audits

2 Pages

-

HyPET Recycled Flake

2 Pages

-

HyPET Preform Systems

4 Pages

-

Hylectric Machines

4 Pages

-

HyCAP Beverage Closures

4 Pages

-

Ultra Valve Gate Technology

4 Pages

-

H-MED AE

2 Pages

-

Altanium Neo2

2 Pages

-

Company Overview

26 Pages

Archived catalogs

-

Altanium Delta3

2 Pages